UV aging test chamber technical parameters:

Here is the technical parameter list of the ChiuVention UV Aging Chamber. If you need uv test chamber with other parameters, please contact us directly. Our technical team and sales team can solve these things quickly and perfectly.

| Temperature Range: | RT+10℃~70℃ |

| Temperature Uniformity: | ±3℃ |

| Temperature Fluctuation: | ±0.5℃ |

| Humidity Range: | ≥75%RH |

| Distance Between The Center of The Lamp: | 65~70mm |

| Spicemen Center And Lamp: | 55mm |

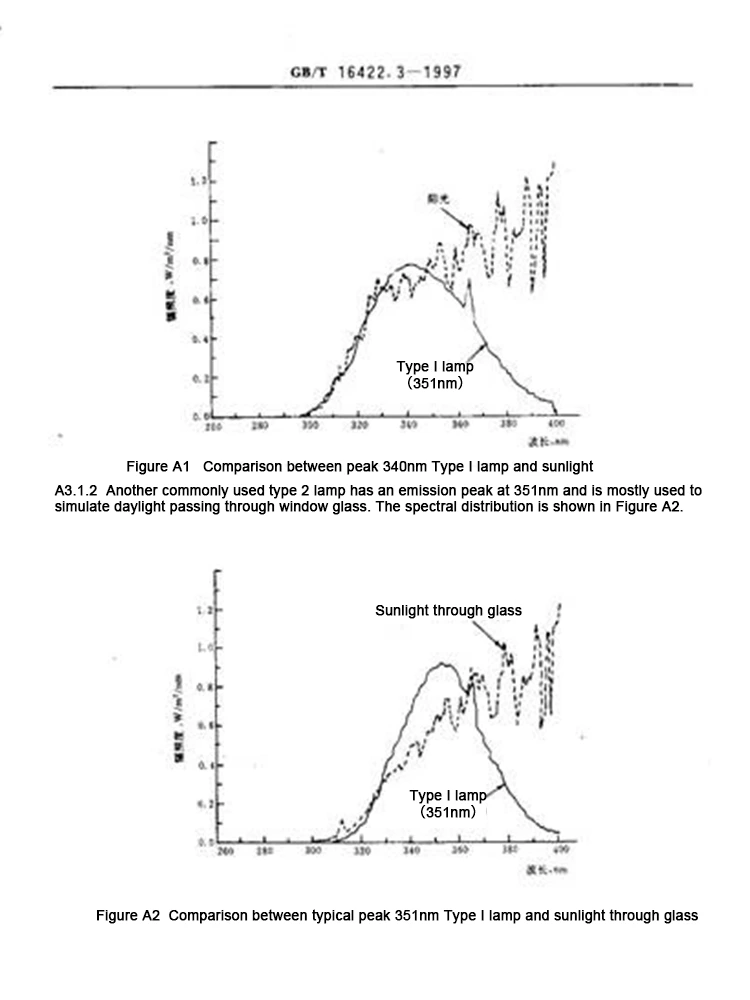

| Ultraviolet Lamp: | UV-A 340 |

| Wavelength: | 320-400 nm (domestic) |

| Standard Spicemen: | 75×150mm |

| Irradiation Intensity: | 0.55 ~ 1.0W / C ㎡ within adjustable. |

| Spray System: | Spray water for 18 minutes, and stop spraying for 102 minutes. Besides, you can set the time. |

| Test Cycle: | Usually, UV irradiation at high temperatures and dark humid condensation cycles with 100% relative humidity. |

Structure and material of UV accelerated aging chamber:

- Studio Size: 450 × 1165 × 500mm (Depth × Width × Height)

- External Dimensions: D600xW1325xH1480mm

- Inner Liner Material: SUS304 Stainless Steel Plate

Shell Material: SUS304 Stainless Steel Plate - Lamp: UVA-340 UV Lamp, Two Rows Of 8, 40W/Only (8 In Total) (Q-Lab, Usa)

- Water Source And Consumption: Clean Water Or Distilled Water 8 Liters / Day (Customer To Provide)

- Control System: The Company’s Own Research And Development Of Touch Screen PLC Controller

- Main Components: Omron And Chint

uV light test chamber Safety Protection Device:

- Earth Leakage Protection

- Overload Power Failure Protection

- Over-Temperature Protection

- Audible Alarm

- Water Shortage, Grounding Protection

Why Choose ChiuVention UV aging tester?

One Machine Multi-purpose, Wide Range of Applications:

It can apply to coatings, inks, paints, and plastics. Also, it applies to adhesives, cars, and cosmetics. It also applies to metals, electronics, drugs, pigments, fabrics, and more.

Full Energy-saving State Operation, Energy Saving and Power Saving:

The refrigerant is environmentally friendly. It has fine control over the flow rate. This allows it to achieve full energy-saving control. Cut power use by balancing temperature and humidity. It saves energy and the environment.

Customized Service:

As a UV test chamber manufacturer, we can provide the OEM UV weather test chamber. If you have special needs, such as UV aging capacity or required specs, please contact us. We can also help with quality control, production capacity, and other key factors. We can manufacture test chambers according to your requirements.

3 Major Devices Real Simulation of Environmental Climate:

UV lamps: 8 UV lamps, simulating the sun irradiation

Heating: including heating module, simulating high temperature situation

Rain: pinhole spraying system, simulating the rain effect

Realistic Simulation of Sunlight, Rain and Dew, Damage to Various Materials:

UV chamber only takes a few days or weeks to reproduce the damage that takes months or years to occur outdoors. It includes fading, discoloration, and loss of brightness. Also, chalking, cracking, blurring, and embrittlement. There are also oxidation and loss of strength.

3 Wide Design, No Fear of Challenges:

Voltage Versatility: Different regions with different voltages can operate normally

Humidity Adaptability: Whether desert or rainforest, our technology remains effective in diverse environmental conditions.

Temperature Resilience: To cope with the global climate, no fear of heat and cold can operate stably.

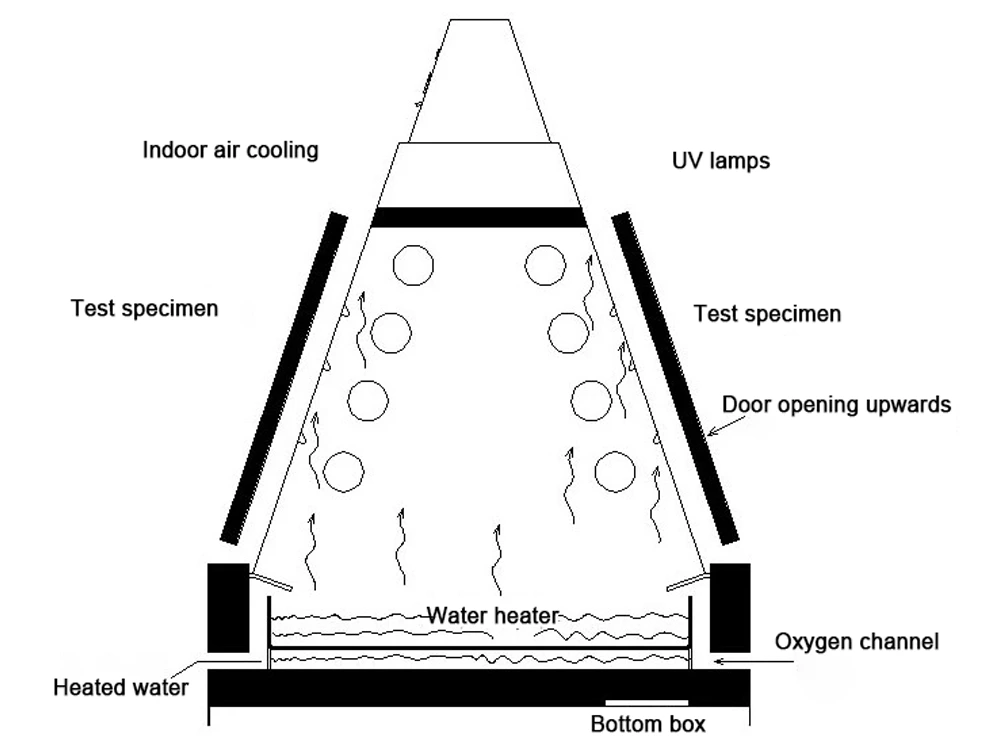

Accelerated UV chamber Product construction:

- We use corrosion-resistant metal materials to build the chamber structure. It includes 8 fluorescent UV lamps. It also has a water tray, a test sample holder, a system to control temperature and time, and an indicator.

- The test sample and its bracket form the box’s inner wall. And their backs are exposed to the cool air at room temperature. This is due to the temperature difference between the test sample and the air inside the box. Condensation forms on the test sample’s surface. It makes stable conditions. The test box should produce natural air convection. This happens by the bottom, through the box’s outer wall, and the test sample’s channel.

- The low water tray of the heating box generates the water steam. The water depth is not more than 25 mm, and there is an automatic controller for the water supply. And the water tray should be cleaned regularly to prevent water scale formation.

- Measure the sensor on the black plate. Put the black plate in the center of the test area. The thermometer measures 30 to 80℃ with a tolerance of ±1℃. Light and condensation phase control should be carried out separately, with the condensation phase by the heating water temperature control.

- We should put the UV weathering chamber in the test room. The room has a temperature of 15~35℃. It should be 300mm away from the wall. We should also protect it from other heat sources. The air in the test room should not be strongly circulated not to affect the light and condensation conditions.

UV light aging Test conditions:

To ensure proper testing conditions and maintenance of the test frame, follow these steps:

Set Up The Test Frame And Test Sample.

Set up the test frame in a good spot. Make sure it is stable and has proper access to the lamp and the test chamber. Attach the test sample securely to the test frame. It should face the fluorescent lamp directly. Make sure to put the sample correctly for accurate testing. If the sample does not fill the frame, fill the rest with a blackboard or another suitable material. This will help keep the test chamber closed and minimize external interference. Position the blackboard to fill the empty space within the sample frame.

Set The Desired Test Temperature.

You can choose from three temperatures: 50°C, 60°C (best), or 70°C. For condensation, 50°C is suggested. Ensure the temperature tolerance uniformity is maintained within ±3°C during the test. This will help ensure consistent and accurate results.

Select The Desired Cycle For The Light And Condensation Stages.

You can choose between 4 hours of light and 4 hours of wetness. Or, you can have 8 hours of light followed by 4 hours of wetness.

Monitor the operating hours of the fluorescent lamps.

When a row of lamps reaches 400 to 450 operating hours, it’s time to replace that row. This helps maintain consistent lighting conditions throughout the test.

Precautions of UV Aging Test Chamber:

- Note the operating hours of the fluorescent lamps. After reaching 400 to 450 operating hours, it is time to replace each row of lamps. The other lamps follow the lamp cycle and replacement mode. They compensate for the loss caused by lamp aging. This mode of operation ensures that the service life of each lamp is 1600 to 1800H.

- During lamp replacement, dry and clean the water tray to prevent the formation of scale. Remove any water, debris, or scale that may have accumulated. This will ensure optimal performance and longevity of the test setup.

- Put the new fluorescent lamps into their proper positions. Follow the recommended lamp cycle and replacement mode. These will make up for lamp aging. This will help maintain the service life of each lamp between 1600 and 1800 hours.

- Double-check all connections. Check the water tray is clean. Ensure the test frame is ready to use.

Test Samples and Performance Evaluation (UV Aging Test Chamber):

- Assessment of appearance: Primarily evaluates the appearance of paint, plastic and rubber. It can also evaluate other items as necessary. You can also check gloss, color, and chalking. As well, you can check for spotting, blistering, cracking, and size changes. You should use the instrument for quantitative project testing. It’s for things like gloss, color, and difference.

- We assess mechanical and other properties. We test rubber for tensile strength, elongation, and hardness. We also test for plastic impact strength. We test for elongation at break, and for tensile and bending strength. We may also need to specify other performance tests.

UV accelerated aging chamber Test area diagram:

Lamp distribution: (4 imported lamps on each side, a total of 8)

The lamps are in four rows, in two rows. The lamps in each row are in parallel. The distance between the centers of the lamps is 70 mm.

The lamp power is 40W and the length of the lamp is 1200 mm. The range of uniform working area of the test chamber is 900×210 mm.

Spray head distribution: The spray head distribution is shown in this figure. It has 4 round spray nozzles on each side, 8 in total. They are in the middle of the horizontal line.

Sample Rack Test Area: 21 sample racks, each specification: 75X150MM. (ten on one side, eleven on the other)

The nearest parallel surface of the lamp surface fixes and installs the test sample at a distance of 50 mm.

The test box remains fixed in size, measuring 75 mm wide, 100 mm high, and 2.5 mm thick.

Spectral Distribution Chart:

Equipment Overall Structure Diagram

uV testing Equipment to meet the standards:

ChiuVention accelerated aging test chamber meets the following standards:

- GB/T14522-93 National Standard of the People’s Republic of China “Plastics, paints, rubber materials, artificial climate accelerated test methods for mechanical industrial products”.

- GB/T16422.31997eqv ISO 4892-3:1994 “Plastics laboratory light exposure test methods”.

- This product conforms to the standard: GB/T 14522-93 ASTM G 154, ISO 4892-1 ISO 11507 ASTMD 4329

UV Aging Test Chamber factory Pre-sale instructions:

About the Product

We guarantee the product is new and genuine. Besides, we will debug the whole machine, then pack and ship. Please rest assured that the purchase.

Appearance of UV Aging Chamber

We carefully pack the outer packaging. Then, we deliver it to our long-term logistics partner.

Color Chromatic Aberration Problem

The shooting will be due to the scene and brightness causing color difference. You can find customer service to shoot the video. Please prevail in kind, thank you for your understanding.

After-sales Service About UV Weathering test Chamber

UV Test Chamber Quality Assurance Period:

The equipment’s quality assurance period is one year. It is calculated from the date of the acceptance report. Both parties sign the report.

After-sales Guarantee for Our Accelerated Weathering Tester:

- The warranty has passed or the failure was human-caused. After finding the fault, the company quotes the repair cost to the customer. They base the cost on the difficulty and parts’ price. If the customer agrees, the technician quickly makes the repair.

- During the warranty period, the seller is responsible for failures. The failures are caused by the equipment itself. They will solve them. Equipment damage due to operating errors or other human factors is not included. After the warranty ends, fixing the equipment will cost for spare parts and a service fee.

FAQ About UV testing machine

The UV aging chamber tests how well a product can resist ultraviolet rays. It uses eight 40W UV fluorescent lamps to simulate sunlight or artificial light. This is mainly for non-metallic material products.

The aging chamber uses a xenon lamp. It can simulate the full sunlight spectrum. This lets it reproduce the destructive light waves in different environments. Compared with UV aging chambers, it also simulates sunlight. But, it embodies “full sunlight” more. This is because it can produce UV, visible light, and infrared light. In short, the xenon lamp aging chamber simulates sunlight. The UV aging chamber imitates the sun’s damaging effect.

UV aging chambers simulate UV radiation from sunlight. They perform accelerated aging tests on materials. This will predict the materials’ durability in the natural environment. Compared to the natural environment, you can control the test conditions in a UV aging tester. So, in a shorter time, the tester can see how materials age under different UV intensities. This allows for quicker and more accurate assessment of materials’ performance. But, the UV aging tester’s results are incomplete. They do not fully show how the material performs in nature. UV radiation, temperature, and humidity in nature will impact the material. They will cause it to age. These factors may not be fully simulated in the UV weathering tester. So, UV aging tester test results should be a reference. They should not be an absolute standard.

The length of a UV ageing test and how many hours it is equivalent to are relative. This depends on the equipment, test conditions, and material properties. Generally, 1 hour of UV ageing test equals about 27 days of natural climate exposure. UV rays are part of solar radiation. UV rays vary in intensity and frequency. This varies with the time and location of climate exposure. Therefore, evaluations and comparisons need to be made on a case-by-case basis.

- UV aging test chamber operation process, be sure to maintain an adequate water supply.

- The test phase should minimize the time to open the door.

- The sensing device inside the chamber does not suffer a strong impact.

- Non-specialised operators shall not be operated at will.

- Please get in touch with us when the equipment is not able to solve the problem by yourself.

- Ultraviolet radiation is a strong hazard, especially for the eyes. Therefore, the operator should minimize exposure to ultraviolet radiation. Contact time should be less than 1 minute. It is recommended that the operator with protective goggles and sheaths.

- When the equipment is not working, you should keep it dry. Therefore, it is necessary to drain the water after operation and dry the studio and box.

- After using, you should use the plastic cover to avoid dust intrusion. If there is dust, you also need to remove it.

- UV-A, UV-B, and UV-C and other ultraviolet light wavelengths better simulate outdoor aging. They speed up the aging of the material and greatly shorten the test cycle.

- The tester can do many aging tests quickly. It speeds up the material’s aging. It can also quickly assess the material’s weathering and life.

- The UV aging test chamber has a temperature and humidity system. It can be set to match different conditions. At the same time, you can also adjust the UV intensity and time. Do this to meet the test needs of different materials.

- Ultraviolet aging tester records the parameters of the material in the aging process, such as temperature, humidity, UV irradiation intensity and so on. These data can be used to analyze and assess the aging performance of the material and provide a scientific basis.

- Through the use of UV aging tester, can be obtained in a shorter period of time the aging performance data of the material, thus reducing the time and cost of the actual exposure test.

The UV aging test chamber simulates sunlight’s UV radiation. It helps to test the effects on various materials. This simulation allows for assessing materials’ weather resistance and light stability. Materials exposed to prolonged sunlight may undergo oxidation. They also may fade and wear. The UV tester lets researchers and manufacturers conduct controlled experiments. They replicate these conditions in a lab..

We can summarize the primary functions of the UV aging test chamber as follows:

Simulation of UV Radiation:

The chamber replicates the UV component of sunlight. It subjects materials to controlled doses of UV radiation.

Weather Resistance Testing:

It enables the evaluation of how materials withstand long-term exposure to UV rays. This test helps predict their performance in outdoor environments.

Light Stability Assessment:

The chamber allows for examining materials’ colorfastness and stability under simulated sunlight. This test is particularly relevant for products exposed to outdoor conditions.

Preventive Testing:

Manufacturers can pre-test materials to identify potential oxidation, fading, or degradation issues. This test contributes to proactive quality control.

Laboratory Experimentation:

Researchers can conduct better experiments to understand UV radiation’s impact on different materials. This test helps in developing more resilient, durable products.

The UV aging test chamber is crucial for quality assurance. It helps enhance product quality and optimize manufacturing processes. It provides insights into the effects of UV exposure on materials.

The UV tester works by simulating the ultraviolet component of sunlight to test samples. You can set different temperatures and humidity to simulate various weather conditions. This helps achieve the effect of testing in a natural environment. The sample’s surface will be exposed to UV rays during the test. They have a similar effect on the material as sunlight radiation. Observing changes in the sample helps understand the material’s weathering and light stability properties.

1. Automotive Industry:

Used to test the weather and UV resistance of automotive exteriors to ensure the stability and safety of automotive use in different climatic conditions.

2. Plastic Industry:

It is used to test the weather and UV resistance of plastic products to ensure that they are not easy to use in outdoor environments and do not rupture.

3. Coating Industry:

Used to test the weather and UV resistance of coating materials to ensure that the coating does not quickly fade and flake outdoors.

4. Electronics Industry:

Used to test electronic products’ weather and UV resistance to ensure that they are not easily aged and fail when used outdoors.

5. Construction Industry:

This industry tests construction materials’ weather and UV resistance to ensure that they are not easily aged and damaged when used outdoors.

- Temperature Calibration:

First of all, the temperature control system of the test chamber needs to be calibrated. Calibration can use a standard thermometer to measure the temperature of all places inside the test chamber. It can then compare this temperature with the one shown by the chamber’s control system. If there is a difference, the control system needs to be adjusted so that it can accurately control the temperature inside the test box. - Humidity Calibration:

You must regularly calibrate the humidity system. It’s in the UV aging test chamber and is also necessary. You can use a standard hygrometer to measure the humidity inside the test chamber. Then, compare it with the humidity shown by the test chamber system. If there is a difference, make the right adjustments. They will ensure that the test chamber’s humidity can be controlled. - UV Radiation Calibration:

Calibrate the UV lamp. It is a key factor in testing how materials weather. So, we need to calibrate the UV lamp’s intensity and wavelength often. You can use a pro UV radiometer to measure the UV radiation in the test chamber. Then, compare it with the standard values from the manufacturer. If there is a difference, the UV radiation lamp needs to be adjusted or replaced. Time Calibration:

The test chamber also needs to calibrate the time control system. Calibration can be done by comparing the time inside the test chamber with the standard time. If there is a deviation, the time control system must be fixed. This is to ensure that it can show and control the time in the test chamber.

Calibration of the UV weathering tester should be carried out by a professional technician with the relevant knowledge and experience. You should determine the calibration frequency based on the use of the test chamber and the manufacturer’s requirements, and it is generally recommended to carry out calibration once a year.

After calibrating, you should develop corresponding calibration records that include the calibration date, calibration personnel, calibration data, and other information. You can use these records as the basis for inspecting and tracking test results.

Regularly calibrating the UV aging test chamber can ensure its condition and the accuracy of the test results. It can also improve the credibility and repeatability of the test data. In practice, meeting the calibration specification is vital. It ensures the test’s quality.

(1) Select a suitable UV lamp to ensure its radiation covers the entire product surface.

(2) Place the product to be tested in the test equipment to ensure that the exposed area of the product is uniform.

(3) According to the actual use of the environment, set the appropriate irradiation dose and maintain a certain period of irradiation.

(4) Remove the product periodically and conduct various performance tests, such as those for weather resistance, appearance changes, and material strength.

(5) Repeat the cycle until the end of the test conditions.

(6) Compare the data before and after the test to evaluate the durability and performance changes of the product.

(1) The test equipment should be equipped with control and monitoring functions for parameters such as radiation, temperature and humidity to ensure the accuracy and reliability of the test.

(2) Choose suitable UV lamps to ensure that the radiation emitted can match the actual use of the environment.

(3) The test process needs to be closely controlled to avoid the influence of external factors on the test results.

(4) After the end of the test, to carry out comprehensive data analysis and summary, to provide reference for product improvement.

- Ultraviolet light is harmful to the human body, in the operation of the equipment should pay particular attention to try to avoid ultraviolet light, the use of equipment, personnel should wear goggles and gloves.

- The test box door is prohibited to open unless special circumstances.

- In the exposure of sunlight, only for the test of ultraviolet light, not including visible light and other sunlight, etc., the thermal effect produced by ultraviolet light is very small, the test temperature will not play a big role, so its temperature is mainly determined by the surrounding air temperature, affecting the exposure of ultraviolet light line test.

- The ultraviolet aging test requires a variety of ultraviolet lamps, different lamps emit ultraviolet light is not the same, will affect the test results, domestic lamps and imported lamps compared to imported lamps are more complete, the use of a longer period of time.

- After the equipment failure, should immediately stop the equipment running, check the fault solution and then restart.

UV lamps in use, sometimes the lamp is not lit, sometimes lit or flickering. This is because the fluorescent UV aging tester generally use electronic ballast, electronic ballast wiring for jack type. So some times because the details of the production process is not very good, it is easy to lead in the lamp corner line in the connection with the electronic ballast there is no reliable hidden trouble, in the future use of the process will appear gap offline, poor contact and other issues. Or because the lamp voltage is too high and the transformer does not match, please measure the lamp power and related parameters.

UV lamps in use, sometimes the lamp is not lit, sometimes lit or flickering. This is because the UV tester uses electronic ballasts. The ballasts have jack-type wiring. Sometimes, bad production details cause the lamp corner line to lead into the ballast. The ballast has no reliable hidden trouble. In the future, gaps, poor contact, and other issues will appear in use. Or, the lamp voltage is too high and the transformer does not match. Please measure the lamp power and related values.

(1) UV lamp aging, need to replace the UV lamp;

(2) UV lamp power density is small, need to replace high-power UV lamp;

(3) UV paint photoinitiator is not enough, change UV paint;

(4) short curing time or low ambient temperature, lengthen the curing time;

(5) the distance between the lamp and the object is too far, increase the ambient temperature to adjust the distance.

1) The lamp operating current is too high, please re-select the correct voltage;

2) Lamp surface with dirt or splash dirt at high temperatures, pay attention to the lamp surface cleaning;

3) False connection, reconnect;

4) Short circuit, reconnect;

(5) Power supply voltage mismatch, need to replace the lamp.

The fluorescent UV aging tester has a water tank. It is used to hold water for heating. This simulates the nighttime condensing in nature. The tank is stainless steel. So, the operator, when operating the equipment, adds tap water instead of deionised water as specified. The operation will lead to the equipment’s use in about 3 years. The sink will rust because the heated water’s poor quality corrodes it. This forms rust until the sink and other things rust through.

Deionised water is not used as the rules say. Tap water is used instead. So, the heating tube is in tap water and high-temperature tap water for a long time. The heating tube is made of steel. It is filled with magnesium powder. So, heating tap water long-term causes the surface of the heating tube to corrode. It is made of stainless steel. It causes rust.

1. In the installation of the equipment, our products must be prepared with other neighbouring environmental testing equipment or walls to retain a certain space between the range, in order to facilitate its work.

2. In order to make the equipment in the experiment, can be balanced and stable to play out its function and performance advantages, our environment temperature should be selected in the perennial temperature of 13 ℃ ~ 25 ℃ this range, relative humidity is not greater than 80 per cent, bear in mind that the installation of the ambient temperature of the temperature can not be too large, so as not to cause the accuracy of the experiment, caused by the unnecessary error; 3.

3. Before installation, we must use the level tester in the installation of the ground test to see if its level is balanced, is not in line with the equipment should be installed in the level of the ground standards.

4. Installation of the environmental requirements of the same as other environmental testing equipment, must be in the absence of direct sunlight, well-ventilated places.

5. The environment where the equipment is located, the surrounding air can not contain dust, impurities and other particles.

6. The equipment can not be installed in combustible materials, explosives and high-temperature heat source place, so as to avoid equipment explosion, endangering the personal safety of technicians.

The calibration of a UV ageing tester involves a number of aspects to ensure the accuracy and reliability of the test. The calibration process consists of the following main aspects:

UV Radiation Calibration: this refers to the calibration of the intensity of radiation produced by UV lamps. A calibrated radiometer is usually used to measure the UV radiation intensity to ensure that it meets the required standards. When calibrating, the radiometer needs to be placed in the irradiated area of the UV lamp, the measurement results recorded, and the distance of the UV lamp adjusted or the lamp replaced according to the results, so that the UV radiation intensity meets the standard requirements.

Temperature control calibration: involves controlling the temperature inside the test chamber within specified limits. A calibrated thermometer or temperature sensor is used to measure the temperature inside the test chamber at different locations and the measurement results are recorded. The temperature controller inside the chamber is then adjusted based on the measurements so that it accurately controls the temperature.

Humidity control calibration: This refers to controlling the humidity inside the test chamber within a specified range. A calibrated hygrometer or humidity sensor is used to measure the humidity inside the test chamber at different locations and the measurement results are recorded. The humidity controller inside the chamber is then adjusted according to the measurement results so that it can accurately control the humidity.

Calibration process: Specifically at the operational level, for example, for the QUV UV aging tester, the calibration process includes pausing the test, installing the blackboard temperature plate, loosening the temperature sensor cover screws, placing the machine’s temperature sensor in a thermowell along with the calibrated thermometer, and waiting for the sensor temperature to stabilise to carry out a temperature via the control panel Calibration.

Follow Standard Operating Procedures: Standard operating procedures need to be followed when calibrating, according to the instrument’s instruction manual. For calibration equipment such as radiometers, thermometers, hygrometers, etc., they should be regularly inspected and calibrated so as to ensure their accuracy and reliability. Regular calibration of the UV aging tester is recommended to ensure the accuracy and reliability of the instrument.

The above steps and precautions can effectively ensure that the calibration of the UV aging tester is accurate, thus providing strong data support for the weathering and durability assessment of materials.

The use of a UV Weathering Tester involves several steps to ensure the accuracy and safety of the test. The following are the basic steps in using a UV Aging Tester:

Equipment Positioning and Power Connection: First, place the equipment in a smooth position and make sure it is level. Then, switch on the main power cord, taking care to distinguish the zero wire, and push the circuit breaker on the case or circuit board.

Water Filling and Sample Placement: Connect the external pure water hose to the water inlet of the unit, and the water tank at the bottom of the unit will automatically fill with water. Next, place the samples on the sample rack, if there are not many samples, you can turn on the front light only.

Setting parameters: After closing the door of the box, turn on the power switch on the panel, at this time the instrument displays the main menu. Set parameters such as temperature, irradiance, etc. as required.

Start the equipment: after completing the parameter setting, start the equipment. Specific temperature, irradiance settings and instrument operation can refer to the instrument manual.

Sample Removal: At the end of the total test time, all instruments stop working, at this time you can open the door of the bin to remove the test article2.

CAUTION: During use, care should be taken to keep the equipment clean and maintained to ensure the accuracy of the test. At the same time, follow the safety operation procedures to avoid safety hazards in the testing process.

By following the above steps, the UV aging tester can be effectively used to conduct weathering tests on materials, thereby assessing the performance and life of the materials in the actual use environment.

1. The influence. of environmental humidity:

UV aging test chamber in different environmental humidity standards, a variety of raw materials, architectural coatings, and plastics and other chemical substances, photochemical deterioration of the effect of a huge difference, and they are the same as each other on the provisions of the environmental humidity standards, and therefore the actual environmental humidity standards by the relevant standards expressly provided.

2. Influence of support frame and installation:

The thermal characteristics of the various support frame and installation methods, the temperature of the test specimen will have a serious impact on the composition of the test specimen, should also be taken into account sufficiently, so that its thermal conductivity characteristics can mean the typical application of the specific conditions. Most of the test specimens are installed in the actual requirements of the thermal characteristics of a variety of rising support frame or padded bracket, the padded bracket and installation methods and specimen placement and other detailed provisions should be related to the requirements of the standard.

3 The temperature

Ultraviolet aging test box direct link or stop the light link, the box temperature should be required by the experimental procedure flow (A, B or C) to control, the relevant standards should be according to the machine and equipment, or components of the booking of the main purpose of the requirements of the direct link in the need to exceed the temperature of 40 degrees or 55 degrees.

4. Cyclone rate

Close to the surface of the test piece of the cyclone rate size in addition to affecting the test piece of the temperature, and even also make the monitor radiation intensity of the open temperature difference between the pile of significant deviations. Typically, a rate of 1 m/s causes the temperature of the thermoelectric stack to decrease by about 20%. See in the reasonable manipulation of the box temperature (or) the standard in addition, to solve the cyclone rate of various aspects of the test, and as far as possible to choose a low rate. When adjusting the temperature in the box, the wall of the box can be cooled by heating or water to prevent the selection of high speed cyclone.

5.Ultraviolet aging test chamber surface environmental pollution

Dust and other surface air pollutants will be more serious, changing the digestion and absorption characteristics of the surface layer of the illuminated object. Unless otherwise required, the test should ensure that the specimen is cleaned up, but when identifying the effectiveness of surface air pollutants, the relevant standards should require the specimen to be treated with metal surface treatment and other necessary contents.

6. In the ozone and other environmental pollution vapour

Ultraviolet aging test chamber in the lamp source in the short-wave ultraviolet radiation source caused by ozone, generally according to the effect of positive spectrometer kinetic energy all over the radiation source filter discharged out of the environmental test chamber, because the ozone and other environmental pollution vapour will affect some of the deterioration of raw materials in the whole process, unless otherwise required by the relevant standards, it is necessary to discharge this harmful substance out of the box on the.

UV aging test chamber instrumentation are installed in the top of the equipment, so there is a problem: in the equipment for heating work, sometimes a test will be done continuously for several days, or even weeks, the laboratory temperature can reach 60 ℃, and some laboratories do not install air conditioning, in the hot summer heat is rising, resulting in instrumentation will be subjected to high temperature for a long time ravaged by the long term in the high-temperature environment, the instrument is easy to malfunction.