UV chambers are one kind of aging test equipment. It uses fluorescent UV lamps to perform accelerated weathering tests on materials. It simulates the UV radiation and condensation to get the material weathering results. The test samples were exposed to moisture and sunlight and subjected to reciprocal cycling. At the same time, the test was conducted by increasing the temperature. Sunlight is simulated by fluorescent UV lamps. Moisture effects are then simulated by spraying or condensation. Non-metallic materials can be subject to artificial light and sunlight aging tests in the UV chamber.

UV Aging Tester

Product Principle and Function Of UV Aging Chamber

The UV tester simulates the environmental conditions of the natural climate. Such as UV, darkness, high temperature, condensation, high humidity, and rain. By reproducing these conditions and combining them into one cycle. It allowed us to perform several cycles. During this process, the lamp amplitude illumination, and spray status can track. It quickly simulates the condition of items in the outdoors for extended periods of time. See whether the product has discoloration, chalking, blurring, strength loss, and other phenomena. Also, the destructive power of dew and rain reproduces. UV light makes up only 5% of sunlight, but it is a major contributor to the loss of durability of outdoor products.

UV lamps are categorized into different types. The types of UV lamps are classified according to the total energy of the UV light. A fluorescent UV lamp that emits less than 2% of its total light output below 300nm is referred to as a UVA lamp. A fluorescent UV lamp that emits less than 300nm and more than 10% of the total light output, is referred to as a UVB lamp. In general, short-wave UV is the more commonly used. UV lamps generally produce ultraviolet light; infrared and visible light are not produced. Test results will vary with different lamps. UV lamps should select for the actual exposure application.

Conditions of Use in UV Weathering Climate Chambers

- The ambient temperature: 5 ℃ ~ +28 ℃ (average temperature within 24 hours ≤ 28 ℃);.

- Ambient humidity: ≤ 85%.

- The machine placed before and after the right and left 80 centimeters can not place things.

UV aging tester main function:

- Illumination (irradiance can display, adjusted, and calibrated)

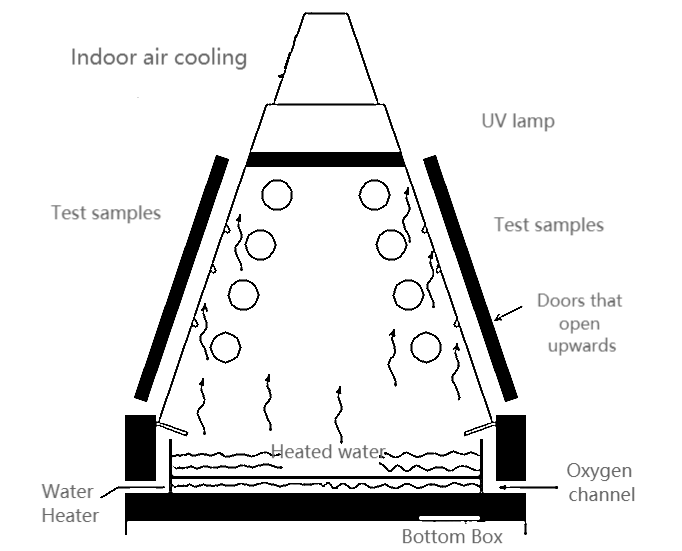

- Condensation (Heated water pan produces water vapor in the box. A temperature difference is created between the inside and outside of the box. The temperature difference causes dew to form on the surface of the sample plate)

- Spray (8 nozzles, total flow rate of 7L/min, simulating natural rain)

Distribution of sprinkler heads

Types of uv aging test chamber

UV aging testers can divide into four types according to the test standard and demand. Benchtop UV aging, UV weathering, photovoltaic UV, and photovoltaic UV wet freezing are these four. According to the test chamber for different standards and industries to differentiate between.

Benchtop UV aging:

do a pure UV aging irradiation test.

UV weathering:

It mainly simulates condensation and UV radiation. The results of material aging are obtained by conducting accelerated aging tests.

Photovoltaic UV:

For the photovoltaic and solar industry to do the aging test.

Photovoltaic UV wet freeze:

As an indispensable test instrument for the PV module industry. It can do photovoltaic module thermal cycle, wet freeze cycle, and double 85 test. It confirms the negative temperature impact after high temperature and humidity. And thermal failure and fatigue of components due to repetitive temperature changes. Besides, it determines the thermal stress of PV modules to high humidity. It also tests the component’s long-term resistance to moisture penetration.

Test conditions:

- Test specimen fixture on the test frame. When the specimen faces the fluorescent lamp without filling the sample frame. The inner wall of the chamber must remain closed and the sample holder filled with chalkboards.

- Test temperature. The light can use 50, 60, 70 ℃ three kinds of temperature, priority recommended 60 ℃. 50°C is the temperature of the condensation stage. ±3°C is the tolerance uniformity of the temperature.

- Two cycles of illumination and condensation can choose. 4H condensation and 4H light or 4H condensation and 8H light.

- Each row of lamps needs to replace after the first light 400~450H. Other lamps cycled and replaced to compensate for lamp aging losses. This allows each lamp to maintain a service life of 1600 to 1800H.

- To avoid the formation of scale, the water tray should keep clean and dry when replacing lamps.

Lamp Distribution

Evaluate test samples and performance:

1. Assessing Appearance:

Coatings are primarily rated for appearance. Rubber and plastics can also evaluate for appearance if necessary. The items to check are gloss, color change, chalking, blistering, and dimensional stability. Should try to use instruments for quantitative project testing, such as gloss, and colorimeter.

2. Mechanical and other performance evaluation:

General rubber materials for tensile strength, hardness measurement, elongation at break, and bending strength. If necessary, other performance test items can specify.

Two types of exposure

The specimen surface temperature is an important parameter when doing the aging test. Generally, high temperatures speed up the degradation process of polymers. The test temperature should depend on the material and the aging properties. Carbon arc and xenon lamps emit more infrared light than fluorescent UV lamps. Convection heating of the specimen surface by hot air. Thus, the temperature difference between air and the surface of the specimen won’t be significant. The equipment is available in the following two exposure methods. Customers can also choose other ways. But, the exposure conditions in the test conditions should state.

Folding exposure method 1

The specimen was subjected to a light exposure period. Then enter the cycle test without irradiation period. The test period must conduct under the provisions of the relevant standards. If the cycling conditions are not specified, the following cycles are recommended.

It should irradiate for 4 or 8 hours at a black standard temperature of 60°C ± 3°C. Then unirradiated condensation exposure for 4 hours required at a black label temperature of 50°C ± 3°C.

Note:

Some polymers (e.g. PVC) have age degradation that is sensitive to temperature. Irradiation exposure temperatures below 60°C are recommended to simulate colder climates. To ensure that conditions are balanced across exposure periods. Irradiation or condensation exposures choose with the least exposure period of 2h.

Overall structure of the equipment

Folding exposure method 2

Continuous cyclic test with irradiation exposure timed water spray. The test period is specified under the relevant standard. If the cycle conditions are not specified, the following cycles are recommended. Irradiation exposure at a black standard temperature of 50°C±3°C and relative humidity of air (10±5)% for 5 h. Irradiation was then continued for 1 hour at a black label temperature of 20°C ± 3°C and water spray.

Note:

①:The exposed surface of the specimen moistened by condensation through a moisture condenser. The heating of water in the container below the specimen holder creates moisture.

②:When Mode 1 is not met, the relative humidity in the exposure chamber can control. Or spray the specimen with an aqueous solution simulating acid rain or pure water. Refer to GB/T 9344-88 for water requirements.

Summary

UV chamber is a simulation of light aging test equipment. By simulating sunlight, and condensation, and mimicking natural humidity. The state of an article in the outdoors for months or years can reach in a UV chamber for a few days or weeks. For example, cracking, peeling and other material deterioration occurs. It does with UV light exposure and a dark humid condensation cycle with humidity at 100%. It used in paints and coatings, automotive industry, wood products, and anodized films.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]