ChiuVention Aging Test Chamber Manufacturer

ChiuVention specializes in manufacturing aging test chambers. Our mission is to provide our customers with high-quality and innovative products.

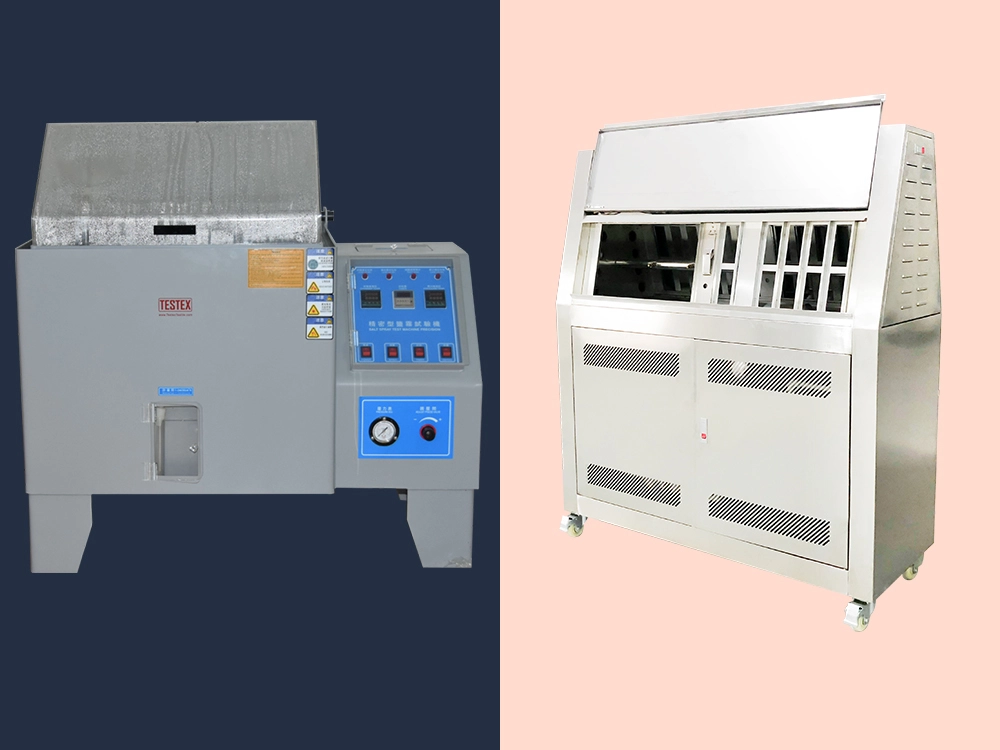

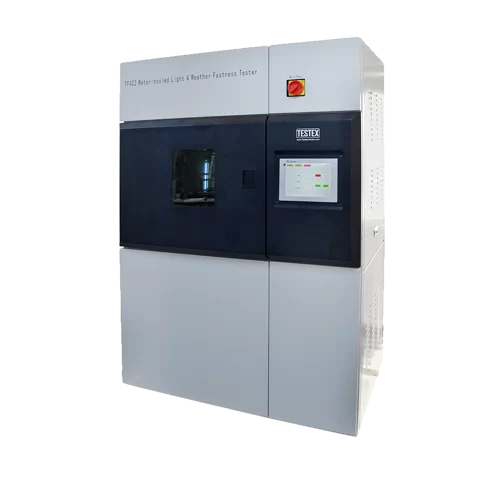

Our aging test chambers not only accurately replicate product aging under actual use scenarios but also feature outstanding temperature, humidity, and pressure control capabilities to serve various testing requirements.

ChiuVention not only maintains strict control over product quality but also provides excellent customer service. Our team comprises an experienced group of experts. Therefore, we can provide customers with customized solutions to ensure that they meet the requirements of diverse industries and applications.

If you are seeking a trustworthy manufacturer of aging test chambers, ChiuVention is a good option worth exploring. We will always help our customers achieve success in product development and quality control.