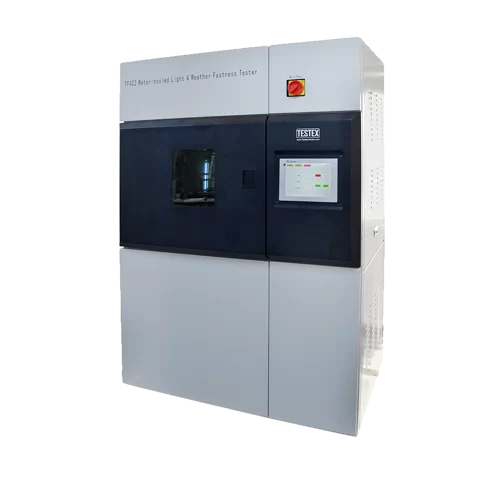

the main technical parameters of Air-cooled Xenon Lamp Weatherproof Test Chamber

| Blackboard Standard temperature control range: | 50~130℃, resolution 0.1℃。 |

| Blackboard panel temperature control range: | 45~125℃, resolution 0.1℃ |

| Testing chamber temperature control range: | 30~85℃, resolution 0.1℃。 |

| Testing chamber humidity control range: | 10~95%RH(Bright cycle≤70%RH,Dark cycle≤95%RH),resolution 0.1%RH。 |

| Time control of test range: | 0~9999hours59min; precision±1min。 |

| Control of irradiance range: | 0.8~2.20W/m2 @420nm,±0.02W/m2 @420nm;(@340nm,@300-400nm,@300-800nm)digital setting, automatic compensation. |

| 0.2~0.8W/ m2 @340nm ±0.01W/m2 @340nm; | |

| 30~80 W/m2 @300-400nm ±2W/m2 @300-400nm; | |

| 400~1100 W/m2 @300-800nm ±10W/m2 @300-800nm; | |

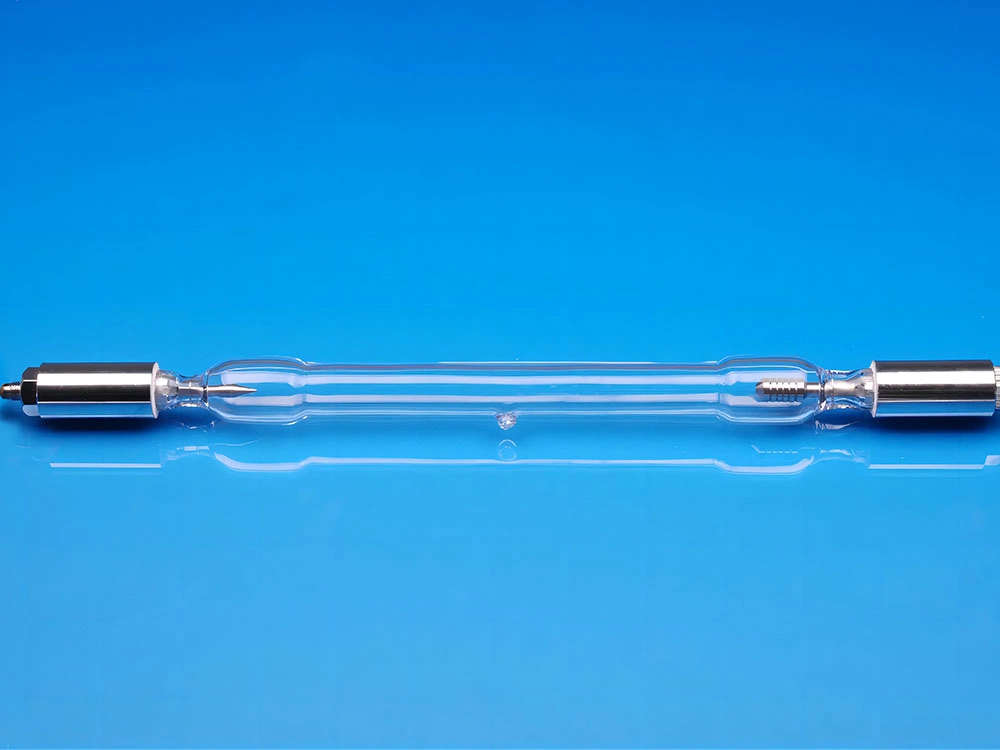

| Light source: | Rated power of xenon arc lamp: 4.5KW. |

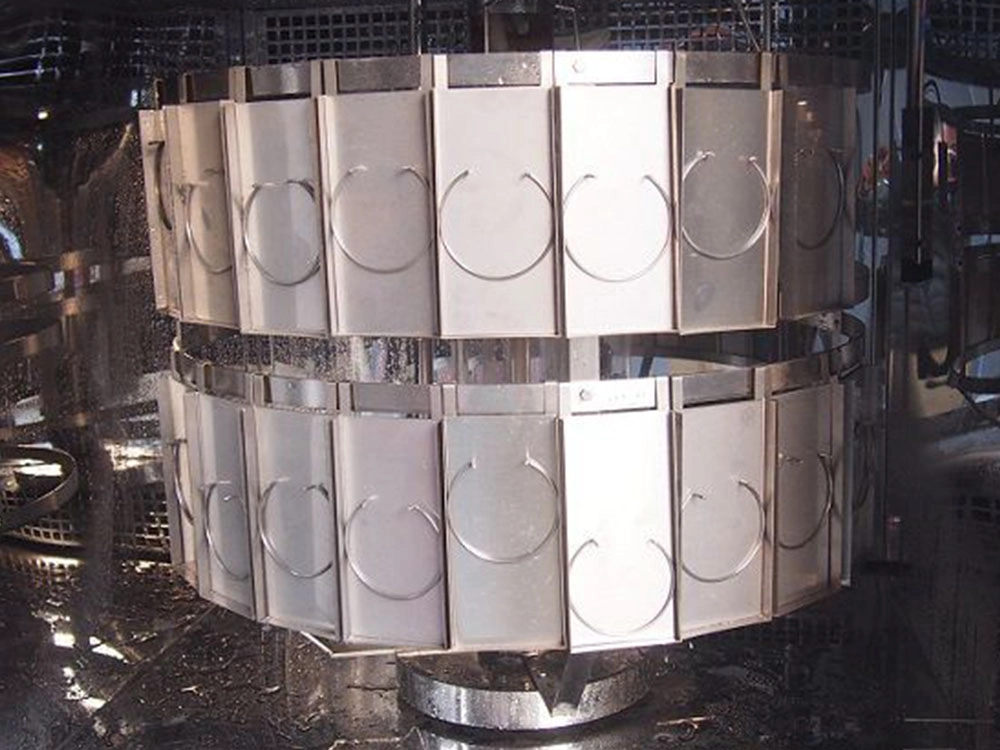

| Specimen: | a.Rotation speed of specimen holder: adjustable between 1-7rpm. |

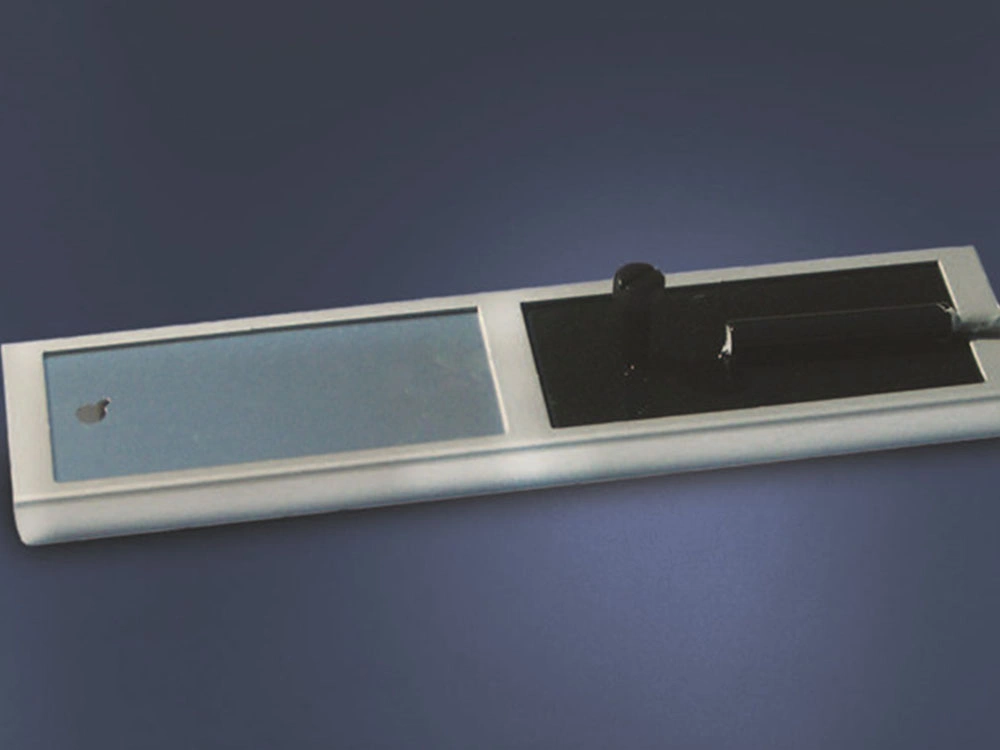

| b.Dimensions and amount of specimens to be mounted and clamped: 35 pieces of 145×75mm sample plates or 46 pieces of 145×45mm sample plates. | |

| c. Individual timing for each specimen gripper≤10000h。 | |

| d.Specimen thickness≤4mm。 | |

| Power source: | 3-phase 4-wire system. The ground wire needs to be external. |

| External dimensions: | 1260×850×1880mm(L×W×H) |

| Weight: | 400kg |

light fastness testing machine comply with the following standards

Meets the following criteria but is not limited to

- GB/T 8427, GB/T 14576, GB/T 8430, GB/T15104-2006, GB/T15102-2006

- ISO 105-B02, ISO 105-B04

- AATCC 16

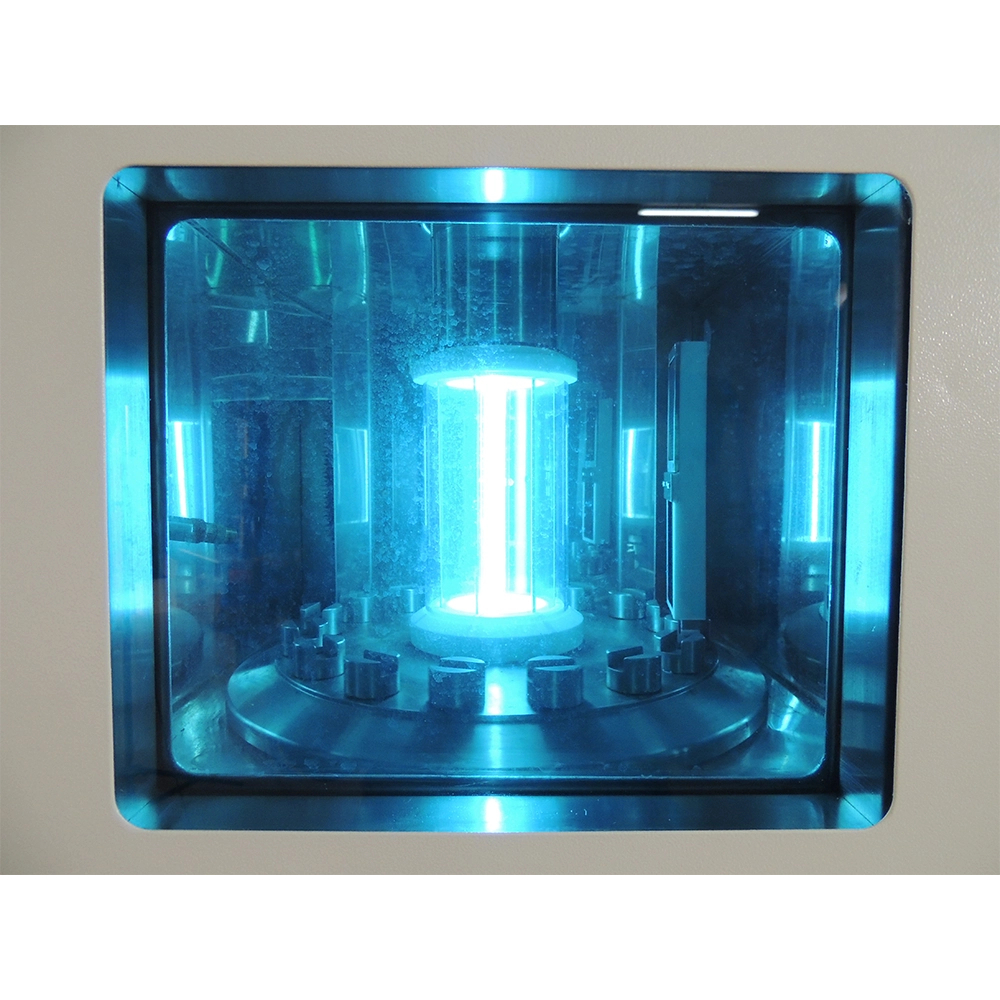

Main characteristics of the xenon arc test chamber:

Superior performance, advanced light source

The light fastness tester uses a powerful 2.5 kW long arc xenon lamp that faithfully mimics the solar spectrum. It uses cutting-edge wireless transmission and detection tech. It uses light energy conversion to provide energy directly. It does not need an external power supply. Optical filters are made of high-quality fluorine material.

Superior energy efficiency and longer test durability

The filters have high transmittance. They let over 95% of light through. They are an eco-friendly solution that cuts energy use. 1000 hours of continuous testing.

Intelligent control and real-time monitoring:

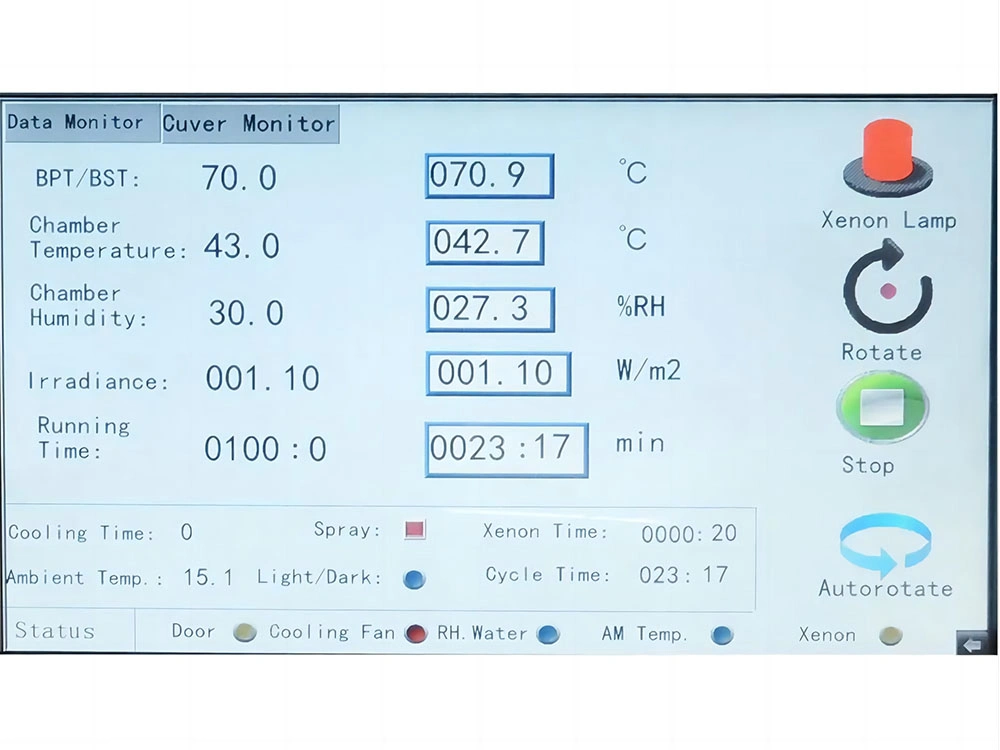

You can set the digital irradiance. It has real-time monitoring and automatic closed-loop adjustment. You can choose from control bands at 340 nm, 420 nm, 300-400 nm, and 300-800 nm. It has a standard black panel thermometer. It has synchronized RF transmission for accurate sample status. It has an intelligent multi-stage ultrasonic humidification control system. These features ensure stable and precise test conditions.

Versatile and easy to use:

Multiple operating modes (spray, alternating, rotating and rotating) simulate real climatic conditions. All sample racks have a timer. It helps test different samples. It cuts costs and protects from power failure..

User-friendly interface for easy control:

It has a large 10.4-inch colour touch screen. It is to reduce membrane panel failures. Provides various test monitoring modes (animation, digital, curve) for easy and clear control.

FAQ About Air-cooled Xenon Arc Test Chamber

An air-cooled xenon lamp weathering tester is a device for testing the weathering performance of materials by simulating natural climatic conditions. The tester simulates natural sunlight, oxidation and other climatic conditions by means of a xenon lamp light source system, which enables materials to be evaluated realistically and accurately under different climatic conditions. During the test, the specimen is placed inside the test chamber, and the air circulation formed by the air duct system makes the specimen subject to the effects of different climatic conditions, such as temperature, humidity, ultraviolet rays, sunlight, etc., so as to assess the weathering performance of materials and coatings and improve the reliability and competitiveness of products.

- According to the need to select the correct test parameters, including temperature range, humidity range, radiation spectral distribution and radiation time.

- Ensure the safety and stability of the sample, and promptly dispose of any wastewater, exhaust gas or other waste that may be generated after the test.

- Follow the equipment operation manual and safety operation procedures to ensure the safe use of the test chamber and samples.

- Regularly calibrate the temperature, humidity and radiation parameters of the test chamber to ensure the reliability and accuracy of the test.

- Pay attention to the reasonable use and maintenance of the test chamber, in order to extend the life of the equipment and ensure its reliability.

The above are general precautions, specific test methods and procedures may vary according to different experimental requirements, product nature and test standards. It is recommended to refer to the test chamber’s operation manual and follow the relevant test standards and specifications before conducting specific tests.

- Automotive industry: used for automotive parts, body painting, plastic products and other durability testing in different climatic environments. Can simulate high temperature, low temperature, sunlight, humidity and other conditions, to assess the performance and stability of the car in a variety of climatic conditions.

- Electrical and electronic industry: used to test the reliability of electronic products, wires and cables, home appliances, etc. in different climatic environments. It can simulate the conditions of high temperature, low temperature, humidity and dryness to test the durability, anti-corrosion and electrical performance of the products.

- Aerospace industry: used to test the reliability of aerospace equipment and parts in various extreme climatic conditions. It can simulate extreme environments such as high altitude and low pressure, high temperature and high humidity, low temperature and low humidity, etc., to verify the performance and ability of products to withstand harsh conditions.

- Building materials industry: used to assess the durability and quality stability of building materials, coatings, glass, etc. in different climatic conditions. It can simulate environmental factors such as sunlight radiation, wind and rain erosion, temperature change, etc. to test the anti-aging performance and service life of materials.

- Cosmetics and food industry: It is used to test the quality stability and safety of cosmetics and food packaging materials under various climatic conditions. It can simulate sunlight irradiation, high temperature, humidity and other environmental conditions to assess the colour change, physical properties and microbial contamination of the products.

The light fastness tester uses a xenon arc lamp that can simulate the full sunlight spectrum to reproduce the destructive light waves that exist in different environments, and can provide the appropriate environmental simulation and accelerated testing for scientific research, product development and quality control. The Light Fastness Tester can be used for selecting new materials, improving existing materials or evaluating changes in durability after a change in material composition, and can well simulate the changes that occur when materials are exposed to sunlight under different environmental conditions.

Xenon aging testing uses a xenon lamp to simulate the full spectrum of sunlight, including ultraviolet, visible and infrared light. This method provides a more complete simulation of the effects of sunlight on materials and is suitable for materials that are sensitive to the full spectrum. Xenon lamp aging testing has the advantage of providing aging simulations that are closer to actual use conditions, but the equipment is relatively complex and costly.

Carbon arc weathering testing uses carbon arc lamps to simulate the ultraviolet and some visible light from the sun. This method was more common in early aging tests, but due to some differences in spectral distribution from actual sunlight and high equipment maintenance costs, it is now gradually being replaced by xenon lamp aging tests.

The light fastness test determines if dye or pigment colors fade in sunlight or artificial light. Common standards for color fastness to light include ISO 105- B02:2014, AATCC 16-2014, and so on. During the test, expose the samples to light for a certain period, compare the color change with a grey card, and finally assess the color fastness level.

Light Source:

The key difference between UV weathering testing and xenon arc weathering testing is the type of light source used. UV weathering tests use ultraviolet (UV) light, usually in the UVA or UVB wavelength range, to simulate sunlight. Xenon arc lamps, on the other hand, emit a broader spectrum of UV, visible and infrared wavelengths to more fully simulate sunlight.

Wavelength Range:

UV weathering tests usually focus on specific UV wavelengths, such as UVA (320400nm) or UVB (280320nm), depending on the desired test conditions and the material under test. On the other hand, xenon aging tests offer a wider spectrum of UV, visible and infrared wavelengths, which better simulates outdoor exposure to sunlight.

Intensity And Irradiance:

UV weathering tests and xenon lamp weathering tests may differ in terms of light intensity and irradiance levels. UV weathering tests typically supply higher UV intensity levels due to their specific focus on UV wavelengths, while xenon lamp weathering tests may supply a more balanced spectrum with lower UV intensity levels but higher overall irradiance levels.

Testing Standards:

There are different industry standards and guidelines for UV conditioning tests and Xenon conditioning tests, for example, UV conditioning tests can be based on standards such as ASTMG154 or ISO4892, which provide solid guidelines for UV exposure parameters. Xenon conditioning tests can be performed according to standards such as ASTMG155 or ISO11341, which provide guidelines for xenon exposure parameters.

Material Compatibility:

The choice between UV weathering testing and xenon lamp weathering testing may also depend on the type of material being tested. Some materials may be more sensitive to specific wavelengths of UV light, while others may be more sensitive to a wider spectrum. In addition, the effects of light exposure may vary depending on specific material properties, such as colour fastness, fading or degradation mechanisms, which may be better replicated by one type of ageing test than another.

Cost and Equipment:

Another distinction between UV and Xenon ageing tests may be the cost and equipment required. Typically, xenon lamp ageing tests tend to be more expensive compared to UV ageing tests. Xenon arc lamps are often more expensive to purchase and maintain than UV lamps. Xenon adjustment chambers may also require additional equipment for proper ventilation, cooling, and monitoring due to the higher heat output of xenon lamps. UV weathering testing, on the other hand, may require less equipment and maintenance costs, making it more cost-effective for certain applications or budgets.

Test Time:

Test time may also differ between UV weathering testing and xenon lamp weathering testing. UV weathering tests may have shorter test cycles than xenon lamp weathering tests, as they typically focus on specific UV wavelengths and may accelerate the degradation process more quickly. Xenon lamp weathering tests supply a broader spectrum and may require longer test cycles to accurately simulate outdoor weathering conditions.

Application And Industry Suitability:

The suitability of UV weathering testing or xenon weathering testing may also depend on the specific application or industry being targeted. For example, UV weathering testing is often used to evaluate materials and coatings used in outdoor applications such as automotive parts, building materials and outdoor furniture, where exposure to specific UV wavelengths can be a critical factor. Xenon lamp weathering tests have a broader spectrum and may be more suitable for applications that require a more complete simulation of outdoor weathering conditions, such as the automotive, aerospace or textile industries.

Air cooling is a method to dissipate the heat generated inside the xenon lamp aging tester by wind power. The air-cooling system consists of a fan, radiator, shell, etc. The principle is that the heat generated inside the tester is blown into the radiator by the fan, and the heat is dissipated by air flow.

1. Advantages of air-cooled

(1) Simple to install and use: air-cooled cooling system is relatively simple to install, do not need to make too many adjustments and corrections. It is also relatively easy to use, without much maintenance.

(2) Relatively inexpensive: air-cooled systems are relatively inexpensive, more economical than water-cooled systems.

(3) Low maintenance costs: air-cooled system components are relatively simple, maintenance costs are also relatively low.

2. Disadvantages of air-cooled

(1) Relatively low cooling efficiency: compared with water-cooled, air-cooled cooling efficiency is low, and prolonged use can easily lead to equipment failure.

(2) Noise: air-cooled system requires a fan to dissipate heat, so the noise is relatively large, the use of which is not suitable for places with high noise requirements.

The cleaning of the xenon lamp aging tester mainly includes daily cleaning, cleaning and replacement of filters, and maintenance and cleaning of the water circuit.

Daily cleaning:

Regular cleaning is the key, use a soft cloth or hoover to gently clean, avoid the use of water or chemical cleaners, so as not to damage the electronic components.

For stainless steel materials, use stainless steel cleaner for cleaning; for baked enamel appearance, use a wet water rag to wipe clean, avoid using stainless steel cleaner to prevent the baked enamel surface from peeling off.

Filter cleaning and replacement:

When the M14 message appears to prompt the replacement of the lamp, you can carry out filter cleaning or replacement work to improve the efficiency of maintenance.

For the Q-SUN Xe-2’s window IR filters, they should not only be cleaned, but also replaced periodically with lamp replacement to ensure accurate irradiance.

The filter cleaning procedure includes removing the screws that hold the filter in place, removing the filter for cleaning, and performing an irradiance calibration after the cleaning is complete.

Maintenance cleaning of the water circuit:

Maintenance cleaning of the water line includes periodic cleaning of the water pan and lines to remove water flora build-up and other dirt growth.

It is recommended that cleaning be performed every 2000 hours or every four months by shutting off the incoming water supply, replacing the water in the wash pan and lines, and scrubbing with a soft cloth to remove any dirt from the pan.

In summary, the xenon lamp aging test chamber cleaning and maintenance involves daily cleaning, filter cleaning and replacement and water line maintenance and cleaning and other aspects to ensure the good operation of the test chamber and extend the service life.

Calibration alarms for xenon lamp aging testers cannot be skipped, as calibration is a critical step in ensuring the accuracy and reliability of the equipment.

Xenon lamp weathering testers are used to test the weathering resistance of materials by simulating natural light and temperature conditions. Regular calibration is essential to ensure the accuracy of test results and the long-term stable operation of the equipment. The calibration process includes checking the luminous uniformity of the xenon lamp, the accuracy of the temperature control system, the safety of the electrical system, etc., as well as calibrating the light intensity, temperature, humidity, etc., using specialised calibration instruments. In addition, the calibration of the equipment should be carried out in accordance with the manufacturer’s instructions and relevant national standards to ensure that the test conditions are similar to the natural environment so that accurate test results can be obtained.

Any alarms about calibration should not be ignored or skipped as it is related to the reliability of the test data and the performance of the equipment. If a calibration alarm is encountered, the calibration guide of the equipment should be followed and the abnormality should be dealt with in a timely manner to ensure the accuracy of the test results and the normal operation of the equipment. In addition, routine maintenance is also an important measure to maintain the performance and extend the service life of the equipment, including regular cleaning, inspection of the xenon lamp, temperature sensors, heating elements, power cables, connectors, etc..

In summary, the calibration alarm of the xenon lamp aging tester is an important part of equipment maintenance and test data accuracy and should not be skipped. The correct approach is to calibrate according to equipment instructions and standards to ensure that the equipment is in optimum condition for reliable test results.

The wiring process of a xenon lamp aging tester involves several steps, ensuring safe and professional operation is key. The following are the detailed wiring steps:

Connect the power supply: Use a three-phase, five-wire voltage of AC380V ± 10%, 50 ± 0.5 Hz and switch on the earth leakage protection switch. The earth leakage protection switch is an electrical safety device designed to prevent single-phase electrocution accidents during the use of electricity, electrical fire accidents caused by leakage of electricity, as well as electrocution accidents caused by leakage of electrical equipment and electrical wiring.

Connecting the water source: The water used must be distilled (purified/deionised) water, as the use of tap water may have an effect on the product test and can lead to clogging of the water circuit system under prolonged use. This step is critical to maintain test accuracy and long-term stable operation of the equipment.

Installation of the lamp: When installing the lamp, careful handling is required to avoid damage to the lamp. First, open the top panel of the unit, loosen the screws on the epoxy plate, remove the wires from the lamp holder, and then install the new lamp. During installation, make sure that the sleeves on the fixing brackets at both ends of the lamp are straight, thread the lamp from the bracket to the other end of the bracket and tighten the locating screws on both ends of the bracket with a screwdriver. Finally, fix the lamp wire on the bracket terminal, screw it tightly with appropriate strength, and at the same time, grasp the metal fixing bracket with the other hand to prevent the lamp from twisting off due to the rotation of the bracket.

Equipment commissioning and operation: After completing the above steps, you can enter the test data and run the equipment. Xenon lamp aging tester adopts touch screen instrumentation, intuitive data, simple operation. During the operation of the equipment, it is necessary to ensure that the equipment runs continuously until the completion of the test, unless the lamp needs to be cleaned or because the lamp and filter have reached the specified period of use need to be replaced.

Safety always comes first throughout the process. The operator should follow the equipment manufacturer’s instruction manual to ensure that all steps are carried out in accordance with the prescribed safety procedures. In addition, regular equipment maintenance and inspection are key to maintaining equipment performance and extending its life.

The method of hanging the sample in the xenon lamp aging test chamber involves the following steps:

Preparing the samples: Ensure that the size and shape of the samples meet the requirements of the test chamber and that the surfaces are clean and free from oil and impurities. If several samples are to be tested at the same time, ensure that there is sufficient spacing between them to avoid mutual influence.

Placement of samples: Place the samples on the test racks inside the xenon lamp weathering tester. This step is key to hanging the sample, as correct placement directly affects the accuracy and validity of the test.

Setting parameters: According to the test requirements, accurately set the parameters such as light intensity, temperature, humidity and rain cycle. Different materials may require different test conditions, so reference should be made to relevant standards and specifications to set these parameters.

Start up the equipment: Start up the xenon lamp aging tester and begin the aging test on the sample. During the test, the operating status of the equipment needs to be observed regularly, including the luminous condition of the xenon lamp, changes in temperature and humidity, and so on.

End of test: After the test is completed, remove the sample after the chamber has cooled to a safe temperature. The sample needs to be handled carefully when removing it to avoid causing additional damage to it and affecting the evaluation of the test results.

The above steps will ensure that the samples are properly hung and tested in the xenon lamp aging tester to obtain accurate test results.

The installation process of a xenon lamp aging tester involves a number of steps, including preparation, positioning of the equipment, connecting water and power sources, and finally adjusting the equipment.

Firstly, preparation involves reading the operating manual, ensuring that the equipment is not operated until the installation is complete, adding pure water for humidification until the tank is full, and verifying that the drain valves on all parts of the equipment are closed. These steps are to ensure that the unit will operate correctly and safely.

The next step is to locate the equipment. Consideration should be given to a location that dissipates heat and is easy to inspect and maintain. The equipment should be placed on a flat, vibration-free surface and ensure that it is well ventilated to avoid direct exposure to sunlight. At the same time, it should be kept away from heat sources and flammable and explosive substances. Power supply lines and drains should be kept as short as possible, and a place with little dust and moisture and good ventilation should be chosen for installation.

When connecting the water source and power supply, distilled water (purified/deionised water) must be used, as the use of tap water may have an effect on the product test and may lead to clogging of the water circuit system. When connecting the power supply, AC380V±10%, 50±0.5Hz three-phase five-wire voltage should be used and the earth leakage protection switch should be turned on.

Finally, make adjustments to the equipment, including installing the xenon lamp, which involves opening the top plate, loosening the screws on the epoxy plate, taking out the lamp, checking that the sleeves on the fixing brackets at both ends are straight, and then gently holding and releasing the lamp, threading it through from the fixing bracket to the other end of the fixing bracket, tightening the locating screws on the fixing bracket at both ends with a screwdriver, and wiring the lamp Fixed on the bracket terminals. After installation, place the lamp on the device, taking care not to touch the lamp, and then fix it with screws. Finally, place the two lamp head wires of the unit on the cover terminals, make sure that all is secured and then close the top cover of the unit.

Through the above steps, you can complete the installation of the xenon lamp aging test chamber, to ensure that the equipment can operate normally and carry out the relevant aging test.

1. Equipment Inspection: Before starting, ensure that the equipment is in good working condition and check that all connections are normal, including power and grounding.

2. Sample Preparation: Place the sample to be tested on the sample rack in the test chamber according to the requirements, make sure the sample surface is clean and without obstruction.

3. Parameter setting: According to the test requirements, set the required temperature, humidity, light intensity, spray cycle and other parameters through the control system of the equipment.

4. Programming: Select or create a new test programme on the control interface of the device. Usually, these programmes include light cycle, dark cycle, temperature change, humidity change and so on.

5. Start Test: After confirming that all the settings are correct, start the tester to execute the programme. Monitor the parameters during the test to ensure they are running according to the preset programme.

7. End of Test: Once the programme is complete, stop the chamber and remove the sample. Evaluate the sample and record the test results.

8. Equipment Maintenance: After the test, perform routine maintenance and cleaning of the equipment to ensure that it is in good working condition and ready for the next test.

When selecting a xenon lamp aging tester, the following key factors should be considered:

Sample type and size: Firstly, the type and size of the sample to be tested needs to be used to determine whether the size and space of the tester is sufficient to accommodate the sample. This is because different samples may require different space and specific placement to ensure the accuracy and effectiveness of the test.

Functions and specifications: Select the appropriate specifications and functions, such as light intensity, temperature control range, humidity control range, etc., according to actual needs. These parameters directly affect the performance of the test chamber and the environmental conditions it can simulate, so they need to be selected according to specific testing needs.

Brand reputation: choose a well-known brand, its product quality and after-sales service is more guaranteed, can reduce unnecessary risks. Well-known brand usually means that its products have been tested in the market, and have a good user reputation and service system.

Temperature and humidity control accuracy: Make sure the product has high-precision temperature and humidity control functions to meet the test requirements in different scenarios. This is essential to ensure the accuracy and repeatability of the test.

Safety performance: Choose products with reliable safety equipment, such as overload protection, short circuit protection, leakage protection, etc., to ensure that the test process is safe and reliable. Safety performance is an important aspect of the safety of test personnel should not be ignored.

Control system: choose an easy-to-operate control system, it is best to have a friendly human-machine interface interface, user-friendly test parameter settings and data monitoring. An intuitive and easy to use control system can greatly improve the efficiency and convenience of the test.

Durability and stability: choose products with high durability and stability to ensure the reliability and stability of long-term use. This is essential to ensure the long-term use and continued stable performance of the test equipment.

Data logging and report generation function: select the test chamber with data logging and report generation function to facilitate the user to analyse and summarize the test data. This provides convenience for subsequent data analysis and report generation.

Price and cost-effective: according to the actual needs and budget, choose a cost-effective product to avoid excessive pursuit of high-end features and ignore the practicality. Under the premise of meeting testing needs, choosing cost-effective products can better control costs.

Finally, it is recommended that before choosing a xenon lamp test chamber, you can refer to some user reviews and test reports from professional organisations to learn about other users’ experience and product quality, so as to make a more informed choice.

The use of the xenon lamp aging tester mainly includes the following steps:

Equipment Check: Before starting the test, make sure the equipment is in good working condition and check that all connections are normal, including power and grounding, to ensure safety and effectiveness of use.

Sample Preparation: Place the samples to be tested on the sample rack inside the test chamber according to the requirements, make sure the sample surface is clean and unobstructed for the accuracy of the test results.

Parameter Setting: According to the test requirements, set the required temperature, humidity, light intensity, spray cycle and other parameters through the control system of the equipment. The setting of these parameters is essential to simulate specific environmental conditions and accelerate the ageing process.

Programme Editing: Select or create a new test programme from the control interface of the equipment. These programmes typically include light cycles, dark cycles, temperature changes, humidity changes, etc. to simulate different environmental conditions.

Start the Test: After confirming that all settings are correct, start the test chamber to begin executing the programme. Monitor the parameters during the test to ensure they are running according to the preset programme.

End of Test: Once the programme is complete, stop the chamber and remove the sample. Evaluate the sample and record the test results, which will be used to assess the durability and service life of the sample.

Equipments Maintenance: After the test, perform routine maintenance and cleaning of the equipment to ensure that it is in good working condition and ready for the next test.

Please note that specific operating procedures and programme settings may vary depending on the equipment model and manufacturer. Therefore, when using the Xenon Aging Tester, it is recommended to refer to the user manual or guide of the equipment to ensure proper and safe use of the equipment.

- At any time to keep the appearance of clean.

- The machine part please do not place items, in order to facilitate the motor and control parts of the heat dissipation.

- Air-cooled xenon lamp aging test chamber after long-term use, the motor blower device, turntable deceleration device and other parts, if an abnormal noise, should be checked, and pay attention to frequent cleaning and refuelling.

- Electrical components such as high temperature phenomenon, must immediately check the cause of occurrence.

- After each use, air-cooled air-cooled xenon lamp aging test chamber should be kept clean to prevent corrosion.

- The control cabinet cleaned up once a month to prevent excessive dust, affecting the normal operation of the equipment.

- After the test is completed, the total power supply should be closed, wipe clear the water in the chamber, as far as possible to make the test box in a dry environment.

- The control panel of the electrical components, such as failures need to be replaced, do not dismantle, to ensure that the air-cooled air-cooled xenon lamp aging test chamber life.