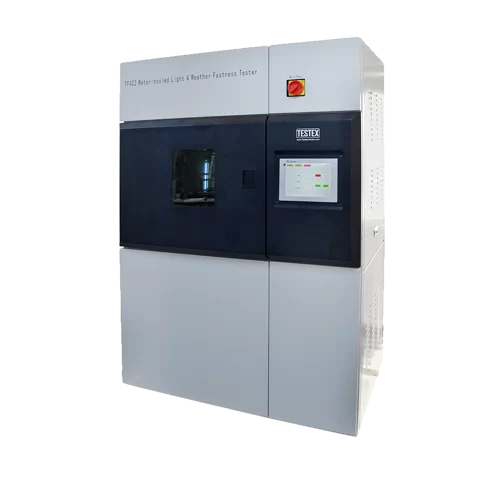

The Specification Of AtmoExplorer Temperature Humidity Chamber

Temperature range: -20°C~+150°C

Humidity range: 20-98%RH

Temperature and humidity control accuracy: ±0.5°C; ±3%RH

Temperature and humidity distribution uniformity: ±2°C; ±3%RH

Heating time: temperature to 100°C within 30 minutes

Cooling time: temperature down to -20°C within 60 minutes

Testable area: 500*750*600mm (D*W*H)

Various Sizes Can Be Customized: such as 80L, 150L, 225L, 408L, 800L, 1000L

ChiuVention Environmental Chamber Temperature And Humidity Control Accuracy

Temperature and humidity control precision: ±0.5°C; ±3%RH

Temperature and humidity uniformity: ±2°C; ±3.0%RH

Rapid Heating And Cooling Of The Environmental Test Chamber

When not loaded, the AtmoExplorer can heat from room temperature to 100°C in 30 minutes. It can also achieve cooling from room temperature to -20°C within 60 minutes.

ChiuVention Climate Chamber Has A Wide Range Of Applications

The temperature and humidity chamber can simulate high and low temperature. They can also simulate high and low humidity.

This temperature and humidity chamber tests temperature and humidity.The test chamber meets requirements in many fields and industries. These include electronics, materials research, medicine, automobiles, and food.

The Constant Temperature Humidity Chambers Operates Stably:

The heating element is made of spring-loaded Nichrome wire. Solenoid valve and other refrigeration auxiliary parts are used first-line brands. France imported “Taikang” full closed type high-efficiency compressor. Humidifier for stainless steel electric steam generator in the form of UL-type humidifier.

Functional Structure Of The Constant Temperature and Humidity Chamber:

7 inch large touch screen, easy to operate.

Built-in LED window lighting, easy to observe the sample.

Equipped with RS-232, USB interface, external computer copy data.

With reservation startup and shutdown function, key and screen lock function.

The program memory fails. The program will start and continue after power is restored.

Power

380V 50HZ 20A 3φ 4 wire

Weight

295kg

Dimension

225L 1330*940*1670mm (D*W*H)

Safety Protection Device Of Constant Temperature And Humidity test Chamber

Anti-burn switch, no fuse switch protection.

Short-term water shortage alarm and long-term water shortage shutdown protection.

Compressor high pressure protection, compressor overheating protection, compressor overcurrent protection.

FAQ About AtmoExplorer Temperature & Humidity Chamber

Environmental test chambers use scientific and technological means to simulate the destructive effects of the natural environment and climate on modern industrial products.

Environmental test chambers on behalf of the test are:

- low-pressure (high altitude) test

- high-temperature test

- low-temperature test

- sand and dust test, etc.

- thermal shock test

- solar radiation (sunshine) test

- rain test

- moisture test

- mildew test

- salt spray test

The constant temperature and humidity test chamber is a device used to simulate continuous temperature and humidity conditions for testing. It usually consists of a sealed test chamber, a heating and cooling system, a humidification and dehumidification system, and a temperature and humidity control system. So, it can provide precise temperature and humidity control, making it possible to test the performance of various materials, products, or equipment under different environmental conditions. It is widely used in the fields of electronics, aerospace, automotive, medical equipment, food, chemical, etc.

Predicting Product Durability in Transit:

Environmental simulation experiments enable the simulation of diverse transit conditions (high temperature, low temperature, humidity, pressure, vibration) to accurately predict product durability during transportation.

Optimizing Product Packaging Design:

Through environmental simulation experiments, different packaging designs can be thoroughly tested to identify the most effective one, preventing damage, contamination, and other issues in the transportation process.

Enhancing Product Quality and Safety:

Environmental simulation experiments assess the performance of product packaging across various environments, mitigating risks of damage, pollution, and other issues during transportation, ultimately improving overall product quality and safety.

Cost Savings:

By conducting environmental simulation experiments, potential issues with product packaging can be identified before transportation, preventing damage, pollution, and other problems. This proactive approach helps in avoiding unnecessary losses and costs.

Reliability Assessment of Products:

Environmental simulation tests replicate real-world conditions, enabling a thorough assessment of product performance and reliability across diverse ecological scenarios.

Product Compliance Assessment:

These tests assist companies in evaluating if their products adhere to specific environmental standards and regulatory prerequisites, ensuring compliance and market acceptance.

Quality Control of Products:

These tests enable companies to implement robust quality control measures during production, ensuring consistent product quality and reliability.

Market Competitiveness of Products:

Enterprises can enhance their products’ competitiveness and market share by evaluating performance and reliability through environmental simulation tests.

High Temperature Caution:

During high-temperature experiments, the machine generates elevated temperatures within the chamber.

Safety Note:

Exercise extreme caution when opening the chamber door during or after the experiment to prevent burns. Additionally, avoid contact with the high-temperature exhaust copper pipe from the freezer to prevent scalds.

Low Temperature Vigilance:

The machine achieves very low temperatures within the laboratory box during low-temperature experiments.

Safety Note:

When opening the chamber door after a low-temperature experiment, take extra care to prevent frostbite. Be cautious of the extremely low temperatures generated, and handle materials with care to avoid any risk of frostbite.

- Maintenance of the constant temperature and humidity test box is very basic. Check whether the screws, parts, connecting lines, and boards are loose, corroded, missing, not solid, dented, or cracked. Also, check if gaskets, plugs, and seals are aging. Deal with any issues in a timely manner.

- The compressor plays a very important role in the instrument, and expensive. Therefore, it is also important to do a good job of routine maintenance of the compressor. The compressor requires a stable voltage; otherwise, it is easy to cause damage. So, install a voltage stabilizer on the test box; do not switch the compressor on and off frequently. Each switch interval should be more than 15 minutes.

- If the equipment motor or turntable reducer is not running well or making a murmuring sound, you should remove any debris and lubricate it with oil.

- Regularly check whether there is leakage or stain deposition in the pump, pipeline and drainage box in the circulatory system, and carry out maintenance and cleaning.

- If you don’t use the constant temperature and humidity test chamber for a long time, turn off the power. Clean and dry the box. Put it in a dry, ventilated place with no direct sunlight. Don’t cover the equipment with plastic to prevent dust. Dust can cause parts to corrode. Even if you’re not using it, it’s best to turn it on once a month for about an hour to protect the compressor.

- To prevent parts from rusting, regularly wipe them with oil. Also, add equipment on time and avoid using tap water with impurities. Instead, use pure water, distilled water, and the like.

You can learn more about daily maintenance information from this blog: How To Maintain The ChiuVention CV340 AtmoExplorer Temperature And Humidity Chamber.

1. Determine the test requirements

Before selecting the environmental test chamber, we must first define their own testing needs. According to the type of items to be tested, test environmental conditions, test time and other factors, you can determine the performance and specifications of the required environmental test chamber.

2. Temperature range and stability

Temperature range and stability are important indicators for selecting an environmental test chamber. According to the test requirements to determine the required temperature range, and then select the corresponding temperature range of the environmental test chamber. At the same time, we need to pay attention to the temperature stability of the environmental test chamber, that is, the temperature fluctuation range. For some precision testing requirements of high scenarios, the temperature stability requirements will be relatively high.

3. Humidity control capability

Some tests need to control the temperature and humidity at the same time, so the humidity control ability is also a factor to consider when choosing the environmental test chamber. According to the test requirements to determine the humidity range, and select the appropriate humidity control ability of the environmental test chamber.

4. Size and capacity

According to the size and number of items to be tested, determine the size and capacity of the required environmental test chamber. Ensure that the selected environmental test chamber can accommodate the items to be tested, and can provide sufficient testing space.

5. Control system and interface

The control system and interface of the environmental test chamber is also a factor to consider when choosing. Modern environmental test chambers are usually equipped with intelligent control systems and friendly human-machine interface, which can facilitate users to operate and monitor the test process. Therefore, when purchasing an environmental test chamber, you need to pay attention to its control system functions and the convenience of the operating interface.

6. Safety and reliability

When choosing an environmental test chamber, safety and reliability are also important. Ensure that the selected environmental test chamber meets the relevant safety standards, with overload, overheating, short-circuit and other protective functions. At the same time, we also need to consider the stability and reliability of the environmental test chamber, can be a long time stable operation, and will not fail in the test process.

7. After-sales service and maintenance

Selection of environmental test chamber also need to consider the supplier’s after-sales service and maintenance support. Ensure that the choice of environmental test chamber can get timely maintenance and technical support to protect the normal operation and use of equipment.

- Predict the durability of the product in transit: through environmental simulation experiments, you can simulate the product in transit may encounter a variety of environments, such as high temperature, low temperature, humidity, pressure, vibration, etc., in order to predict the durability of the product in transit.

- Determine the best design of product packaging: Through environmental simulation experiments, the performance of different packaging designs can be tested to determine the best packaging design, so as to avoid damage, contamination and other problems in the transport process.

- Improve product quality and safety: through environmental simulation experiments, you can test the performance of product packaging in a variety of environments, to avoid damage to the product in the transport process, pollution and other issues, thereby improving product quality and safety.

- Cost savings: through environmental simulation experiments, can be found before the transport of product packaging problems, to avoid damage during transport, pollution and other issues, so as to avoid unnecessary losses and costs.

- The purpose of the test: environmental test to check the adaptability of the product to the environment, to determine whether the product’s environmental adaptability design in line with the contract requirements for acceptance, rejection to provide a basis for decision-making. Reliability test is a quantitative evaluation of the reliability of the product, that is, the product in the specified environmental conditions, the probability of completing the specified function within a specified time.

- Test type: environmental testing is usually a single element test and multi-factor combination of tests, in a certain order of sequential action on the product. Reliability tests are mostly integrated stress test, multiple environmental stress in the same space, the same time on the sample, more realistic simulation of the impact of the use of environmental conditions. In order to improve the accuracy of the test results, reliability, environmental testing has also begun to focus on the development of integrated tests, and actively develop large-scale multi-functional environmental testing equipment capable of simultaneously applying temperature, humidity, vibration, radiation, dust, wind, rain and other stresses.

- Test time:In environmental testing, each test time basically depends on the selected test and the specific test procedures, but due to the time required for each stage of performance testing is different, the test time is much shorter than the reliability test. The reliability test time depends on the value of the reliability index to be verified and the statistical test programme chosen and the quality of the product itself. Its time can not be determined until the total number of hours of the test product to reach the specified value or acceptance, rejection of the judgement.

- The judgement of the end of the test:Environmental testing is not allowed to fail, the product fails when the test fails, the test stops for failure analysis, take corrective measures to improve the design. This is a TAAF process of environmental testing. A reliability test is a test in which the results are expressed in terms of a certain statistical probability, and the number of permissible failures is determined according to the quantitative index of reliability required by the contract and the chosen statistical scheme. The test must always reach a specified total number of station hours before it can be stopped. The test should be developed failure report, analysis and corrective action system.

Refrigerant leakage is one of the common failures of refrigeration systems. If the refrigerant leaks, it will lead to a decline in the cooling effect, or even can not be refrigerated for. To solve this problem, you first need to check whether the connection of the refrigerant pipeline is tight, there is no sign of leakage. If leaks are found, the seals need to be repaired or replaced in a timely manner. At the same time, also need to check whether the refrigerant pipeline cracks or damage, timely repair or replacement of the pipeline.

Refrigerant blockage is also one of the common failures of the refrigeration system. If the refrigerant pipe is clogged, it will lead to poor refrigerant flow and affect the cooling effect. In order to solve this problem, the refrigerant pipeline needs to be cleaned and maintained regularly to remove the impurities and scale in the pipeline. At the same time, care needs to be taken to avoid dropping impurities or foreign objects into the refrigerant pipeline during operation, so as not to cause blockage.

Compressor is one of the core components of the refrigeration system, if the compressor fails, it will lead to a decline in the cooling effect or can not be cooled. In order to solve this problem, the compressor needs to be checked and maintained regularly to ensure the normal operation of the compressor. At the same time, care needs to be taken to avoid overloading the compressor during operation to avoid damage to the compressor. If the compressor appears abnormal noise or vibration, you need to stop the machine in time to check, repair or replace parts.

- Because the temperature can not be maintained, observing the refrigeration unit in the environmental test chamber operation is not the whole process can run; the refrigeration compressor in the natural environment of the experimental equipment operation over the entire process can run, indicating that from the main switching power supply to the refrigeration compressor of the household appliances route is normal, the household appliances system software level is not difficult.

- There is no problem with the circuit system; recheck the refrigeration unit. First, check two groups of refrigeration units at the ultra-low temperature level. The refrigeration compressor exhaust and breathing working pressure are slightly lower than the standard value, and breathing working pressure is a pumping time situation, indicating that the main refrigeration unit refrigerant quantity is not enough.

- With a hand touch of the main generator set R23 refrigeration compressor exhaust pipe and breathing pipe, it found that the exhaust pipe temperature is not high, and the breathing pipe temperature is not low, which also shows the main generator set of R23 refrigerant lacks.

1. Constant temperature and humidity test chamber temperature control accuracy is a key factor in determining the test results. The higher the precision, the more accurate and reliable the test results. Therefore, in the design and manufacture of the test chamber, the stability and accuracy of the temperature control system must be fully considered.

2. In the testing process, humidity accuracy is also very important. The humidity control system of the test chamber must be stable and reliable, and can accurately control the humidity parameters within the specified range.

3. The cooling system of the test chamber must be able to operate continuously at a constant temperature and reach the preset temperature reduction range.

4. The heating device of the test chamber is also a key component, which must be able to reach the preset temperature increase range within a specified time, and be able to maintain a stable temperature throughout the test cycle.

5. The humidification device of the test chamber must be able to operate continuously within the specified humidity range, and be able to maintain a constant humidity level during the test cycle.

First, sensors and instruments. Relative humidity can be measured using solid sensors unaffected by condensation, fast-responding wet and dry bulb sensors, or dew-point meters. Sensors that are sensitive to condensation water, such as lithium oxide sensors, cannot be used. When testing a data acquisition system, the test system should have an appropriate recording device. Usually the data acquisition system is separate from the test box controller. When using graduated recording paper, the accuracy should be ±0.6°C. If wet bulb control is used, the wet bulb and container should be kept clean before each test and the wet bulb gauze should be replaced every 30 days. The wet bulb screen used in the constant temperature and humidity test chamber should be as thin as possible to facilitate water evaporation and keep the sensor surface moist. The water used in the wet bulb system should be equal to the mass of the wet bulb. If possible, the water tank, wet bulb gauze, sensors and other components of the RH measurement system should be visually inspected every 24 hours during the test to ensure expected function.

Second, the wind speed past the wet bulb sensor should be no less than 4.6 m/s. The wet bulb gauze should be placed at the suction end of the blower to avoid being affected by the heat of the blower. Any part of the air round the specimen should be kept between 0.5-1.7m/s.

Third, humidification method. Spray steam or water in the air around the sample. The amount of water humidification should meet the requirements of PH6.5-7.2, resistivity 1500-2500Ω-m at 25 ℃. the water quality is checked regularly (not more than 15d) to ensure that the water quality is qualified. Before spraying water to adjust the water temperature, humidification before spraying water, so as not to damage the test conditions, not directly to the test chamber spray water. In the experimental process produced by the condensation of water should be discharged constant temperature and humidity room.

Fourth, to prevent pollution. In addition to water, no other substances can be in direct contact with the sample to prevent deterioration of the sample or affect the test results, there is no such as rust, corrosive pollutants and other substances can enter the laboratory. In the laboratory, dehumidification, humidification, heating and cooling of the sample shall not change the composition of air, water or water vapour.

1. Stability

Constant temperature and humidity are necessary for accurate experiments. Stability depends on the control system and changes slowly over time. If the chamber is unstable, it will not be able to create accurate experimental conditions, and the results of the experiment will be unreliable. A number of factors can affect the stability of a chamber, including ambient temperature, load capacity, and chamber size.

2. Temperature Control

The main purpose of a constant temperature and humidity tester is to simulate a variety of environmental conditions to help conduct different experiments. However, different experiments require different temperature conditions and the chamber must be able to adjust the temperature in a short period of time. A high quality tester should be able to minimise the temperature adjustment time in order to quickly adapt to various needs.

3. Humidity control

Humidity is another very critical element, because the experimental results need to be obtained at a specific humidity. A high quality humidity chamber can control humidity to a large extent in order to meet the needs of the experiment. As with temperature control, the humidity chamber needs to be able to quickly adjust humidity to meet market demands.

4. Refractive index

The refractive index of equipment and materials inside a humidity chamber is one of the key factors in experimental accuracy. For example, when a laser passes through a device or material, the refractive index will have an impact on the laser’s propagation path and accuracy. To ensure accurate results, the refractive indices of all equipment and materials inside the chamber should be matched as closely as possible.

5. Cleanliness

The cleanliness of the constant temperature and humidity test chamber is a very critical factor affecting the test results. Dust, foreign matter, grease and gas in the equipment can negatively affect the test results. Therefore, high-quality equipment must be frequently maintained and cleaned, and should be regularly calibrated and verified.

6. Age of equipment

The age of the equipment will also have an impact on the accuracy of the constant temperature and humidity tester. Long-term use can lead to equipment aging, and it is difficult to control humidity and temperature after equipment aging. Therefore, regular inspection and maintenance of the equipment is required. High-quality equipment should be able to apply for many years, and this can greatly reduce operating costs while maintaining accuracy..

1、Heat transfer

Inside the box wall of the box before and after the left, right, up and down the heat transfer coefficient of the six surfaces are not the same, some have threading holes, test holes, test holes, etc. resulting in local heat dissipation, heat transfer, so that the box temperature is not uniform, and then make the box wall radiation convection heat transfer is not uniform, affecting the temperature uniformity.

2、 Thermal load

If the constant temperature and humidity test box box placed enough to affect the overall internal heat convection of the experimental samples, will inevitably affect the uniformity of the internal temperature to a certain extent, such as placing the LED lighting commodities, the commodities themselves exist in the luminous heat, to become a heat load, then on the temperature uniformity of the existence of a great impact.

3、Heat radiation

Planning problems lead to the test box in the internal layout, space planning is difficult to achieve uniform symmetrical layout, and asymmetrical layout will inevitably lead to internal temperature uniformity error, this level is mainly reflected in the sheet metal planning and sheet metal processing, such as: the planning of the air ducts, the placement of the heat pipe position, fan power, such as the magnitude of the reasons.

4、Sealing

Box and door sealing is not tight, for example: sealing strip non-customised with seams, gate leakage, etc., and then affect the temperature uniformity of the workspace.

5、Inner wall layout

Because the layout of the inner wall is not the same, so it will lead to constant temperature and humidity test chamber wall temperature will not be uniform, which in turn affects the heat convection inside the workplace to form the internal temperature uniformity error.

6、 The reasonableness of the selection and placement of the sample to be tested

If the experimental target volume is too large, or the experimental target placed in the high and low temperature chamber work room orientation or method is not appropriate, so that the air convection inside the obstruction, will also occur a large temperature uniformity error. For example, the experimental goods placed next to the air duct, seriously affecting the wind cycle, of course, the temperature uniformity will be greatly affected.

1. Light factor: constant temperature and humidity tester different products of the structure of the composition of the intensity of light is also different. Let’s say that the durability of the material, such as plastic, paint, etc., these products materials encounter light, will not produce serious aging phenomenon. Therefore to analyse the material composition of the product equipment.

2. High temperature factor: when the environment due to high temperatures and the surrounding temperature increases, then the intensity of light and the degree of destruction will increase. Temperature and light have no direct chemical reaction, but there is a subtle connection between them. Therefore, when testing the products of constant temperature and humidity machine, it is necessary to grasp the range of temperature used.

3. Humidity factor: usually, some moisture, rain, dew, etc. are the factors that cause humidity. Dew formed by moisture is the main factor of outdoor humidity, and dew is more harmful than rain because the longer the dew adheres to the material, the more it will lead to serious moisture absorption. For example, timber coatings are exposed to sunlight due to rainfall removing the surface aged layer and exposing the unaged inner layer to sunlight, causing further deterioration.

First of all, the relationship between temperature and humidity is manifested through the physical changes of substances. In a constant temperature and humidity chamber, when the temperature rises, water molecules become more active, thus increasing the humidity in the air. On the contrary, when the temperature decreases, the water molecules will become more inactive, thus making the humidity in the air decrease.

Secondly, humidity also affects the temperature inside the constant temperature and humidity test chamber. Under certain environmental conditions, when the humidity increases, the temperature inside the test chamber will rise accordingly. This is because the water molecules will absorb the heat in the surrounding environment, thus increasing the temperature inside the test chamber. On the contrary, when the humidity decreases, the temperature inside the test chamber will decrease accordingly.

(1) The workshop should be kept clean and dry. The room temperature should be within the range of 10℃~30℃ and the relative humidity should be <80﹪RH.

(2) The instrument should be placed on a horizontal, smooth, flame-retardant ground with certain friction.

(3) The working area should be set in a place with less vibration interference.

(4) The instrument should be kept away from objects and equipments which are magnetic or can generate magnetic field.

(5) The instrument shall not be used in areas with explosive hazards.

(6) The instrument shall not be used for a long time in a high humidity or dusty environment.

(1) After opening the box, check whether the parts are loose or not;

(2) This instrument should be installed and positioned on a horizontal floor, and the heat dissipation rate of the machine and easy inspection and maintenance should be considered;

(3) There should be a distance of at least 60cm between this equipment and the wall and any other machines;

(4) Fill the recycling water tank with pure or distilled water until it is about nine minutes full;

(5) Correctly connect the power plug to ensure that the connection is firm (must use three-hole socket, must have a reliable grounding wire to ensure safety);

(6) electrical lines and drain lines, should be possible to shorten

1. Constant temperature and humidity test chamber water available distilled water, deionised water or pure water, do not use tap water, because tap water contains more impurities, will affect the effect of the experiment and the service life of the machine.

2. In the device, wiring before the end of the power supply is not allowed to connect, to avoid electric shock or the occurrence of faulty operation and fault.

3. Constant temperature and humidity test chamber wiring should be correct, and must be grounded.

4. The operator should be familiar with the operation and performance of the test chamber. Also carefully read the operation manual of the test equipment, so that you can avoid operational errors caused by the abnormal operation of the test equipment, thus causing damage to the test samples, test data is not correct.

5. Need to do the ventilation of the test box to clean, easy to accumulate dust, to ensure that the test box can run normally.

6. Constant temperature and humidity test chamber using wet bulb gauze is not any gauze can be replaced. Because the relative humidity reading is based on the difference between temperature and humidity, strictly speaking, but also with the local atmospheric pressure, wind speed, and the wet bulb temperature value and gauze inhalation of water, surface evaporation. These are directly related to the quality of gauze has a close relationship. Otherwise it is difficult to ensure the accuracy of the data recorded by the humidity sensor.

7. The placement of test samples should be avoided close to the wall of the box more than 10cm, for more than one sample should try to put on the same plane. Sample placement should not block the air outlet and return air outlet, to the temperature and humidity sensor should also leave a certain distance. To ensure that the test temperature is correct.

To check the power switch is not plugged in well, if not plugged in well then to give it plugged in well, it is not powered on then the temperature will not change, and also check whether the instrument panel is intact, intact then there will be a temperature display above.

Check that the sensor is not wrapped in gauze. Hold the sensor tightly in your hand to see if there is no change. If there is no change, it is damaged and needs to be repaired in a timely manner to ensure the normal use of the situation.

If test items are too large, affecting the circulation of air and the temperature change, then the changes will become irregular, and their placement will also affect the position. They should be put flat to maintain a smooth surface and kept ventilated so that the temperature change will also be uniform.