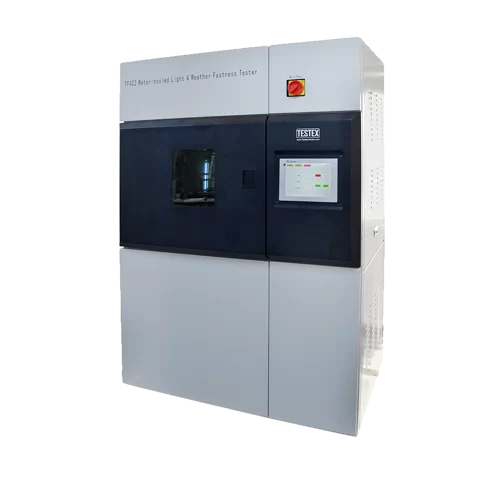

the main technical parameters of Industrial Oven:

| Internal Size | W800*H800*D800MM |

| Temperature Range | RT+10~350℃ |

| Accuracy | Control accuracy ±0.5℃ |

| Distributed Temperature | 50±2℃, 110±2℃, 150±2℃, 163±2℃, 250±3℃, 350±3℃ (no load) |

| Power Supply | Voltage 380V 50Hz |

| Total Heating Power | about 10KW |

| Controller | Located above the door, single door, stainless steel deluxe handle, with explosion-proof locking door buckle. |

Inside material

The plate is aluminum-plated and 2mm thick. The inner cavity is clean and smooth. It is easy to clean and does not leave a residue. It is corrosion-resistant. All the internal materials use low-pollution material. All the internal use of traceless argon arc welding.

Outside material

SECC steel plate, the plate thickness is 1.5mm fine powder baking paint treatment.

Insulation material

High-density glass rock wool 100mm thick, good heat insulation, maximum temperature insulation to ensure that the forced material for high-temperature silica gel, can withstand high temperatures of more than 500 degrees for a long time.

Industry Oven Characteristics:

External and Internal Materials:

SECC steel plate constructs the exterior, which has a high-temperature baking paint finish. So that it can provide a robust external structure.

Internally, SUS stainless steel plates offer excellent corrosion resistance. It will ensure a hygienic and stable internal environment.

High-Temperature Operating Capability:

This industrial drying oven boasts an extensive working temperature range. The range from room temperature plus 10 ℃ to 350 ℃. This enables high-temperature processing in a variety of applications.

Robust Temperature Control System:

Equipped with a fully automatic PID and SSR combination temperature control system. This ensures the accuracy and stability of temperature control. The controller accuracy is ±0.5°C. It is good for applications that need precise temperatures. (PID: Proportional-Integral-Derivative; SSR: Solid State Relay)

Forced Horizontal Air Circulation:

Industrial oven for baking features a new high-temperature-resistant long shaft motor and a turbo fan. So, it achieves forced horizontal air circulation. This ensures even temperature distribution inside the chamber, thereby improving processing consistency.

High-Temperature Resistant Silicone Compression Seal:

This electric industrial oven utilizes a high-temperature-resistant silicone compression seal. So it can maintain internal sealing integrity even in high-temperature environments. This prevents external environmental interference and enhances process stability.

Timing Alarm and Over-Temperature Protection:

Industrial oven bakinghas a timing alarm. It has over-temperature protection. It has an overload thermal cut-off. All these systems ensure safe operation and product quality.

Versatile Construction Options:

Various construction options are available. Options include desktop or vertical cabinets. They have single-phase three-wire or three-phase five-wire power supplies. They also have exhaust hole layouts, door opening methods, and control panel layouts. These options cater to different process needs and site limits.

Why choose the ChiuVention Electric Industry Oven:

Selected materials for durability

The exterior is made of an SECC steel plate. It has a high-temperature baked enamel finish. This provides a sturdy exterior construction. The interior is made from a SUS stainless steel plate. It resists corrosion well. This ensures a hygienic and stable internal environment.

Wide Temperature Range and Uniform Temperature Distribution.

Industrial electric oven uses a new high temperature resistant long shaft motor and turbo fan. As a result, it enables forced air to circulate horizontally. This ensures the temperature is even inside the chamber. The range is from room temperature plus 10 °C to 350 °C. This allows for high temperatures in many uses. This allows high temperatures to be applied in a wide range of applications.

Precise temperature control for a wide range of needs

Fully automatic combined PID and SSR temperature control system. This ensures accurate and stable temperature control. The controller is accurate to within ±0.5°C. It is good for applications with strict temperature needs. This industrial electric oven features high temperature resistant silicone compression seals. As a result, it keeps its internal sealing. It does this even in high heat. This prevents interference from the external environment and improves process stability.

Safe and reliable for testing and easy to clean

Industrial oven electric has a timed alarm. It also has overheat protection and a thermal cut-off for overload. All these systems ensure operational safety and product quality. The plate is plated with 2mm thick aluminum. Its inner cavity is clean and smooth. It’s easy to clean and leaves no residue. The inside uses low-pollution, corrosion-resistant materials. The whole inside is welded with trace-free argon arc welding.

Industrial Oven Temperature control system

Temperature control for the PID microcomputer automatic calculation PV / SV at the same time display, can be set within the machine temperature allowed according to personal wishes of the required temperature, and can be set by the table PID parameters to ensure the accuracy of its temperature control, but also by the table itself with the system self-evaluation of the appropriate temperature control parameters.

Energy saving:

Once the temperature reaches the preset level, the whole machine reduces its power to 10% of its total. This involves shutting down most of the heating wire. It effectively manages electric energy losses. The longer the machine operates, the more pronounced the energy savings are. It uses about one-tenth the energy of similar products in the industry.

The equipment uses high-quality materials and accessories, and the normal service life of the machine is 6-8 years.

Sensitive temperature into the force CA (K) TYPE output of 12V.

The current controller for SSR has no contact Relay to maintain high stability of the current.

The heating material is a honeycomb-type stainless steel heating tube with no pollution and has a long service life.

Air supply system of electric Industry Oven

Forced convection air circulation: the air source is driven by the circulation motor running wind wheel through the electric heater, the hot air from the duct to the inside of the oven.

After use, the hot air is sucked into the air duct to become the source of heating again, thus reducing energy loss and ensuring the temperature uniformity inside the oven,

When the door opening and closing action causes disturbance, the air supply circulation system can be used to quickly return to the operating state temperature value. The motor is imported from Taiwan long shaft high temperature resistanttype, the fan is multi-blade turbine wheel type, high strength, equipped with adjustable air guide plate, so that the wind path runs more smoothly.

Temperature rise rate: RT ~ 100 ℃ about 10 minutes.

Related accessories and safety protection

Super high temperature protection, no fuse switch, motor overload protection, temperature to timer, alarm beep, alarm delay

Timer 9999 seconds ~ 9999 hours (H.M.S switchable and decimal point position setting)

Temperature timer, power off when the time is up, stop heating and alarm

Standard with 2 trays

Application Of Industry Oven

LED Manufacturing

Companies use LEDs in lighting and displays. They need specific processes to make them. They can use this chamber for baking. It ensures the stability and performance of LED components.

LCM Manufacturing

Liquid Crystal Modules are frequently used in displays for electronic devices. This oven can make LCMs. This might involve controlling temperature and drying.

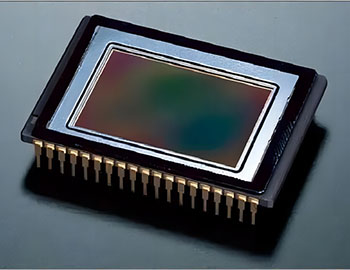

CMOS Manufacturing

CMOS (Complementary Metal-Oxide-Semiconductor) is a critical component of integrated circuits. Temperature and environmental control are vital in CMOS manufacturing. You can use this industry oven for baking and curing steps in CMOS processes.

Optical Lens and Optical Glass Manufacturing

Controlling temperature is crucial in optical manufacturing. It affects the shape and performance of lenses and glass. You can use it in the processes of optical products to ensure their quality.

Fiber Optic Product Manufacturing

Fiber optics play a crucial role in communication and sensing applications. You can use this industrial drying oven

to improve fiber optic products. It can boost their performance and stability. This is done through baking and processing.

Curing Silver Adhesive

Silver glue is commonly used to bond and connect electronic components. This industrial oven can heat and cure silver adhesive to ensure reliable connections.

Industry Oven Warranty matters

- The precision oven is in normal use when the one-year free warranty fails. After that, the second-year material costs are optional.

- The warranty does not cover damage caused by natural disasters or human factors.

- Please use it properly. Please tell our company’s after-sale service if you have any problems. This includes abnormalities, malfunctions, or operational issues.

Note:

Please present the record card at each service. If you lose the card, the warranty period will start from the delivery date.

If there is any trouble, fax us the contact letter. Then, call to confirm. We will serve you quickly.

electric industrial oven For sale

We sell not just environmental test chambers but also electric industrial ovens. We make industrial electric oven chambers. So, if you didn’t find the product you want, you can contact us to query whether we have the industrial electric oven. We will continue to update the industrial oven we sell in the future.

FAQs About Purchasing Electric Industrial Laboratory Oven

- Firstly, it plays an important role in electronic manufacturing. In the manufacturing process of electronic components, the precision industrial oven can control the temperature and humidity of components to ensure their quality and stability.

- Secondly, precision industrial ovens are also widely used in the aerospace and defense industries. Precision industrial ovens can simulate extreme environments. People use them in the making and testing of spacecraft and aircraft. They make sure the craft is reliable and stable.

- In addition, there are many industries that use them. Like automotive manufacturing, precision instrument manufacturing, food processing, and pharmaceutical manufacturing industries.

Firstly, precision industrial ovens can accurately control temperature and humidity, making the manufacturing process more stable and precise.

Secondly, precision industrial ovens have larger heating power and fast heating speed, which can reach the required temperature faster and improve production efficiency.

In addition, precision industrial ovens also have better temperature and humidity uniformity, which can ensure the uniformity of products in the baking process.

Industrial oven equipment is a drying equipment that reduces the oxygen content in the cabinet and carries out heating and baking. The antioxidant maintains the drying and curing of the metal and other relatively oxidized equipment for baking.

We know that semiconductor manufacturing can be subdivided into two processes, the former and the latter. The former process is the processing of silicon materials to manufacture wafers through a number of processes such as step exposure IC planning pattern loaded onto the wafer for the manufacture of integrated circuits; the latter process is to carry integrated circuits on the wafer divided into basic units, through packaging, testing the completion of the integrated circuit products.

In industrial oven equipment in the oxygen-free decomposition of the vacuum environment, the oxygen partial pressure drops to avoid the oxidation and deterioration of the material drying process to ensure that the quality of the dried product and has a fully functional baking effect is good, easy to use, easy to operate and so on, more suitable for application in the semiconductor industry than the general oven.

- Selection: When choosing a precision oven, you need to select the type according to the actual production requirements. First of all, to clarify the nature of the baking material, the number of parameters. Secondly, we should take into account the heating mode of the equipment, temperature range, humidity control, and other parameters. Finally, we should also take into account the appearance of the equipment size, energy consumption and other factors.

- Use: In the use of the precision oven, you need to pay attention to the following points: first of all, to ensure that the installation of the equipment meets the requirements of the place, such as the ground level, well ventilated, etc.; secondly, in accordance with the operation manual for the correct operation, to avoid safety accidents; again, in the process of using the equipment to keep clean and hygienic, and regular maintenance and maintenance.

- Maintenance: To ensure the normal operation and service life of the precision oven, you need to perform regular maintenance. Specifically, it includes cleaning the drying room, replacing the filter, checking the heating element, and so on. During maintenance, you should be careful. Avoid damaging the electrical and mechanical parts inside. This will prevent harm to the equipment’s operation and service life.

An industrial oven is a heating device used in industrial production. It heats objects to a certain temperature for heat treatment. Many industries need them. These include metal and plastic production, food processing, and others.

Industrial ovens use electricity or gas to generate heat. They then transfer the heat to the object using a heating element. Industrial ovens usually consist of a shell, a heating element, a control system, and an exhaust system.

We usually divide industrial ovens on the market into the following categories.

1、Precision high-temperature oven

A conventional oven can reach 200 ℃, with some reaching 300 ℃. High-heat ovens have good temperature control. This comes from their good design and tests. This improves product reliability and practicality. A precision oven is commonly used in many aging tests. People use it in electronics, computers, and communications.

2、Vacuum Oven

The oven is for drying heat-sensitive, easy to decompose, and easy to oxidize substances. It can be filled with an inert gas. This is especially useful for drying complex goods. It’s used widely in substances that are heat-sensitive, easy to decompose, and easy to oxidize. It’s used in the pharmaceutical field, etc.

3、Clean and dust-free oven

Clean the oven to one of three levels of cleanliness: 100, 1000, or 10,000. The higher the level, the higher the requirements. A clean, dust-free oven has a stainless steel outer box and a stainless steel inner box. It also has a dust-free net, an electric heating system, a circulating fan, and a control system. It can work stably under the needed dust-free conditions. For example, it is for drying medicine, chemicals, electronics, materials, and parts without dust. It is suitable for the testing and production of products that have dust-free requirements.

4、Walk-in type large precision oven

The walk-in oven is large and precise. It uses a splicing assembly structure. This is mainly because the product is too big to fit in a normal oven. The splicing structure makes it easy to dry many products at once. This improves production efficiency.

Select industrial ovens to understand their types and uses. Then, choose the right oven based on materials and needs. This helps companies raise productivity and cut costs.

According to the heat source:

- Electric Oven: electrical heating

- Gas Oven: natural gas heating

- Fuel Oil Oven: oil heating

- Steam Oven: steam heating

- Infrared Oven: infrared heating

According to the use of points:

- High-Temperature Oven: higher temperature requirements

- Dust-Free Oven: clean room environment use

- Vacuum Oven: high media requirements

- Clean Oven: higher cleanliness requirements

Classified according to the field of application:

- Food Industry Oven: This oven is suitable for baking bread, biscuits, pastries, and other food.

- Chemical Industry Oven: Suitable for drying and curing raw chemical materials. For example, glue, paint, and other drying and curing.

- Electronic Industrial Oven: This oven is suitable for baking, curing, and other processing electronic components, such as semiconductors, circuit boards, etc., for baking and heat treatment.

- Pharmaceutical Industrial oven: suitable for the manufacture and drying of drugs. For example, drying treatment for pills, popcorn, etc.

- Textile Industry Oven: Suitable for drying and baking textiles. For example, heat treatment for cotton and wool is used.

1. Heating treatment:

The industrial oven heats objects to the required temperature for baking, curing, and sintering.

2. Drying:

An industrial oven removes moisture from an object’s surface using hot air or infrared rays. This achieves the drying effect.

3. Sterilisation:

Industrial ovens in pharmaceutical, food, and other industries sterilize products for safety.

- Follow and obey the operating procedures. Before using an industrial oven, read the instruction manual and operating instructions. Following the steps in the manual will minimize the potential for unsafe operation.

- Use scald-resistant gloves and shawls. In the event of burns or scalds, thermal protection gloves and shawls can help prevent these damages. Not only do these items cut the risk of skin burns by reducing the risk of your body coming into contact with hot surfaces, but they can also prevent more serious damage by preventing clothing from getting stuck in the oven.

- Ensure proper ventilation. Make sure you have good ventilation when operating the oven. Failure to have proper ventilation can cause smoke, fumes, and other harmful gases to build up, which can have a detrimental effect on the operator.

1. Adjust the amount of ventilation

The ventilation of the industrial oven is critical to temperature control. If the ventilation is large, the oven temperature drops too quickly. Restoring the working temperature becomes challenging. Conversely, with small ventilation, the oven temperature becomes excessively high and uncontrollable.

Therefore, when adjusting the ventilation amount, we need to do the following:

- Calculate the ventilation volume accurately. Adjust the vent and air volume as needed.

- Clean and maintain ventilation holes and fans for stable ventilation volume.

2. Choose the appropriate heating method

There are many kinds of heating methods for industrial ovens, mainly electric, gas, steam, and so on. Different heating methods have different effects on temperature control. Electric heating is fast and precise, making it ideal for controlling industrial oven temperatures.

3. Select high quality temperature controller

The thermostat is the core equipment of industrial oven temperature control. Its stability and accuracy directly affect the oven’s temperature control effect. Therefore, it is very important to choose a reliable, high-precision thermostat.

The following aspects need to be considered when selecting the thermostat:

- Control Range:

Choose the appropriate thermostat based on the temperature range. Consider thermostat stability. - Control Accuracy:

Choose a high-accuracy thermostat for precise industrial oven temperature control.

The above are the methods for controlling the temperature of industrial ovens. Adjust ventilation. Choose a heating method. Select a quality thermostat to control industrial oven temperature. This enhances production efficiency and product quality.

- The industrial oven’s hot air circulation system includes an air supply motor, wind wheel, and electric heater.

- The air supply motor moves the wind wheel to release cold air.

- The cold air gets heated by the electric heater to carry heat energy. Subsequently, it enters the drying room via the air duct.

Equipment Failure FAQs

- Malfunctioning temperature control unit: A temperature control unit controls the temperature of the oven. If this device fails, it will result in an inability to regulate the temperature of the oven accurately. Check and repair or replace the temperature control that is not working properly.

- Heating Element Problems: Ovens typically use heating elements to generate high temperatures. If the heating element is damaged or deteriorated, it can affect the heating effect and temperature stability of the oven. Check and replace damaged or deteriorated heating elements.

- Control Panel Malfunction: The buttons, switches, etc. on the control panel may also be faulty, making it impossible to set and regulate the temperature of the oven accurately. Contact a service professional to check and repair the circuit board, control panel, and other components.

- Environmental factors: Environmental temperature, humidity, and surrounding objects all play an important role in the overall power generation equipment’s operating status. Especially the use of electrical equipment for a long time in harsh environments can easily lead to a lack of assurance of its life. Keep the environment around the oven dry to avoid excessive humidity and temperature fluctuations on the equipment.

- Pay attention to check whether the high-temperature oven motor is in reverse rotation. The motor reversal will cause abnormal hot air circulation or less air. This will lead to abnormal temperature.

- Pay attention to the detection of high-temperature oven solid state relay; if the solid state relay is abnormal, it is likely to lead to continuous heating tube heating, resulting in the over-temperature phenomenon.

- Pay attention to detecting the high-temperature oven temperature control instrument parameters set incorrectly. You can restore the factory settings of the instrument. Use the AT self-tuning temperature control system to do it.

- Observe the high-temperature oven temperature probe collection device is not loose or falls off, such as the emergence of temperature control is likely to lead to inaccurate.

- The wind volume adjustment is not consistent, resulting in too large a temperature difference inside the box; pay attention to adjusting the wind volume baffle trim switch to keep the wind speed uniform.

- The oven’s heating element is damaged. It may be the heating tube, heater, etc. They can burn out from long-term use or high temperatures. This causes insufficient heating and lower temperature.

- Poor air circulation inside the oven: Poor air circulation inside the oven leads to uneven temperature distribution and lower temperature. At this time, you can check whether the oven vent is blocked or the fan is damaged.

- Control system failure: the oven’s control system, such as the temperature controller and circuit boards, may fail, resulting in temperature control failure; the temperature can not maintain the set value.

- External environmental factors: External environmental factors such as temperature, humidity, and other changes may affect the stability of the oven’s temperature.

- Poor oven heat dissipation

If the industrial oven heat dissipation is poor, it will lead to the temperature not going up. At this time, you should clean up the oven’s internal dust and deposits, check whether the oven fan is damaged or stuck, troubleshoot, and restart the oven. - Thermostat failure

The thermostat plays an important role in controlling the temperature of the oven. If the thermostat fails, this will make it impossible to control the temperature. It will also cause insufficient heat. At this time, you should check the thermostat to see if it is working properly and replace or repair it if it is damaged. - Heating element failure

The heating element is the key component that ensures the temperature of the oven. If the heating element is damaged, the oven will not reach the predetermined temperature. At this time, you can check the power supply, wiring, and other methods of investigation to see if there is a problem with replacing or repairing the heating element. - Oven air duct blockage

The air duct is the key component for heat transfer. If the air duct is blocked, it will cause the temperature to be uncontrollable. At this time, you should check whether the air duct is blocked; for example, blockage should be cleaned. - Poor sealing of the oven door

If the oven door seal is bad, it will lead to heat leakage and affect the oven temperature. At this time, you should check if the oven door seal is intact and replace it if it is bad.

- Before each use, you should check whether the oven is normal. If there is any abnormality, you should remove it as soon as possible.

- Clean and maintain the oven regularly to keep it in good condition.

- When using the oven, you should follow the use of norms to avoid accidents.

Check if the wind impeller of the industrial oven is reversed, and if it is, replace any two lines of the power cord. The wind impeller of the industrial oven falls. You should open the oven door and remove the top wind impeller cover. Put the wind impeller back in, tighten the screws, and put the cover back on. Check whether the air supply motor is turning. If the power supply is out of phase, immediately shut down the machine and check the power cord. If the motor is burned out, replace it.