Get an Overview of ChiuVention’s Hast Chamber From the Video

technical parameters of the HAST test chamber

This chart includes the main technical parameters of the Highly Accelerated Stress Test Chamber.

| Inner Box Size: | φ400 × D500 mm round test box (can be customized according to requirements) |

| Outer Box Size: | Width ≤ 700mm, Height ≤ 1600mm, Depth ≤ 1100mm |

| Inner Box Material | SUS 316# Stainless Steel Plate Material |

| Outer Box Material | Senior Baking Paint |

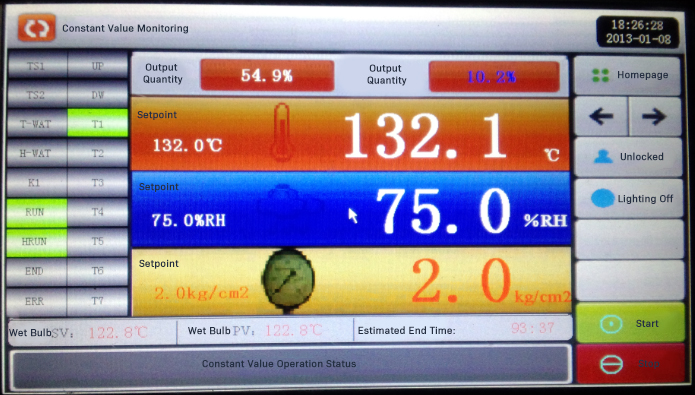

| Temperature Range: | non-satiated 100℃ ~ +135℃ saturated 105~+135℃ |

| Temperature Fluctuation: | ≤±0.5℃. |

| Temperature Uniformity: | ≤±2.0℃. |

| Humidity Range : | 75%RH~100%RH . |

| Humidity Fluctuation: | ≤±2.5 % R.H. |

| Humidity Uniformity: | ≤±3.0% R.H. |

| Pressure Range: | 0.2~2 kg/cm² (0.02~0.196 MPa/2.9~28.45 psi) pressure on the table inside the box, (ambient atmospheric pressure, then add another 1 atmospheric pressure) |

| Temperature Distribution: | ≤± 2.0℃. |

| Temperature Rise Time: | room temperature → + 135 ℃ about 50 min; |

| Boosting Time: | Normal pressure → + 2 kg/cm² about 50 min. External gas source pressurization: about 5 min. |

| Control Object: | Microcomputer + P.I.D. + S.S.R. Automatic calculation control of saturated vapor temperature. |

| Control Mode: | Microcomputer PID Control |

| Control Accuracy: | ≤± 0.5℃. |

| Analysis Accuracy: | 0.1℃. |

| Installed Power: | about 4 kW |

| Maximum Current: | 18A |

Why choose the ChiuVention Highly Accelerated Stress Test Chamber:

Energy Saving and Power Saving, Reliable Operation

The fan has an external rotor. It has a large elevation angle and moves a lot of air. It is quiet at low speeds. It saves 30% of the sound energy of a typical axial fan. The water pipe uses copper pipe and a bell. It has precise design, good air tightness, and low water use. Controller operation adopts a fuzzy algorithm to ensure precise operation.

Automated Control System, More Accurate Control

The water tank is 16L and at the bottom of the box. It uses the latest active automatic water system. This system stops the heating tube from drying. It will not stop the test. The hast test chamber will release the pressure at the end of the test.

Good Sealing Performance, Long Service Life

The packing has special material: heat-resistant rubber foam. Inside the box, the pressure makes it press tightly against the box. This is different from traditional packing, and it can make the packing last longer.

Strictly Selected Materials, Standard Design is Safer:

The hast test chamber has an arc double liner design and a stainless steel round structure. It meets industrial safety container standards. It stops condensation in the test. It also stops moisture. It avoids the direct impact of steam overheating. It meets the UHAST and BHAST test requirements. Meanwhile, the product design separates water and electricity, which is safer.

Intelligent and Easy to Operate

The hast test machine has a timed drying function. It puts the test product in a dry state. When it does, it shows abnormal causes and faults. These events trigger the automatic safety protection, called the critical point limit mode. The controller has a human-machine interface. It has interactive and friendly form design. It has a 7″TFT true color LCD touch screen. It is easy to use.

Easy to Clean and Operate, Good Heat Dissipation

You can monitor and control the hast test chamber remotely via LAN or by connecting it directly to a computer. It has a V-type condenser, a large area for heat dissipation, and efficient cooling. Cold rolled plate baking paint is easy to care for. It resists corrosion and high and low temperatures.

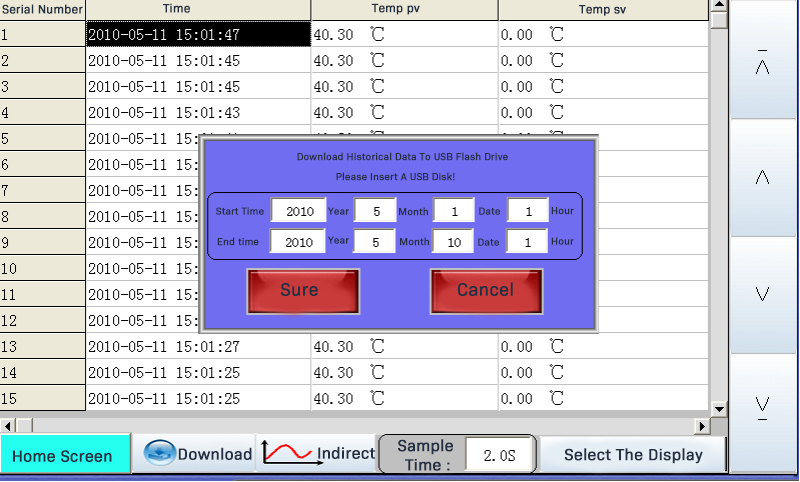

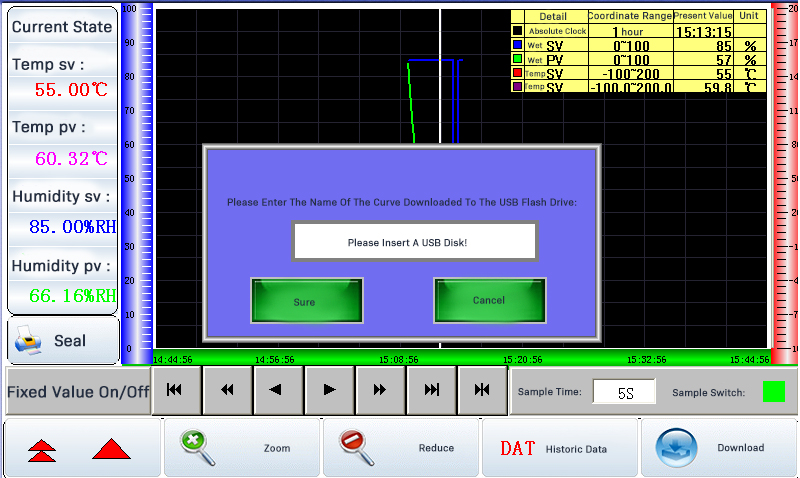

Multi-port Data Support, Convenient to Monitor the Test Process

Hast chamber has a USB interface to copy records directly. This includes historical curves and data. It copies them to the computer to view, analyze, and save. It has an optional RS-232 or RS-485 interface. This interface can control the machine and store data on a computer hard disk. The program has large capacity. It has 269 groups of functions. Each group can be edited in 50 paragraphs.

Multiple safety protection devices so that the Highly Accelerated Stress Test Chamber is more stable

Over-temperature and over-pressure protection is detected throughout the hast test:

- The first stage of the hast test chamber inside the ultra-high temperature protection.

- The second stage of the hast test chamber is inside the humidifier. It has water shortage protection and high pressure protection. It also has a water tank water shortage alarm that turns off the power.

- The second stage of the humidifier tube limit temperature protection.

- The second stage of ultra-high pressure protection.

- Stage 3 has emergency pressure relief. It also has manual pressure relief. And, it has automatic pressure relief..

- Pressure overpressure protection; pressure over limit second protection.

- Temperature limit alarm protection.

- Pressure limit mechanical pressure relief disconnection device.

- Temperature limit over-temperature power-off device.

- Humidifying tube limit temperature cut-off protection device.

- Water shortage protection.

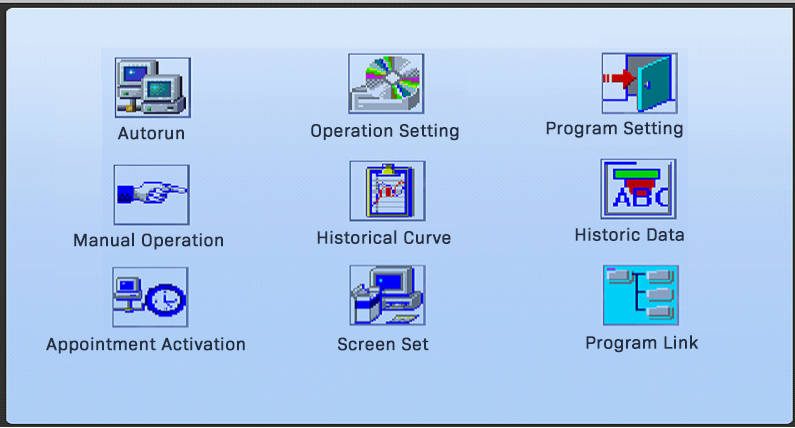

The control system of hast chamber

The original screen is an imported 7-inch microcomputer color LCD touch screen. It has a direct key type. It shows English. It has a wide viewing angle and high contrast. It is for the process controller. It has many PID control functions. Programmable 269 models 13450 steps.

Control Precision of Hast Test Chamber

Accuracy: Temperature ±0.3℃, Humidity ±1%R.H, Pressure ±0.1%R.H.

Resolution: Temperature ±0.1℃, Humidity ±0.1%R.H. Pressure 0.1kg/cm²

The force signal includes temperature and humidity. It uses dry and wet bulb (RTD) PT-100Ω × 2 (platinum resistance).

Pressure input signal 4~20ma.

6 groups of P.I.D control parameters setting, P.I.D automatic calculation.

Dry and wet ball automatic correction.

Interface Display of Climatic Chamber

- Adopting screen talk type, no need to input keys, screen direct touch options.

- Setting (SV) and actual (PV) values are directly displayed.

- The remaining time of the current execution can be displayed.

- Running time totalization function.

- Values are shown as graphic curves. You can also see the program curve execute in real-time.

- Separate editing screen for inputting temperature, humidity, pressure and test time.

- You can switch between Chinese and English at will. The screen shows faults. You can adjust the screen’s backlight..

- The screen display protection function can be timer or manually close the setting.

Capacity and Function Introduction of Environmental Chamber

- The device has 2 groups. Each group can be programmed with 269 models and 13450 steps.

- The program memory fails when the power does. Power restoration starts it. And, it keeps running the program.

- Hast chamber has an RS-232 communication interface. This allows two-way control of the hast test chamber and storage of curve data on the computer hard disk.

- With a USB interface, download historical data at any time.

- Real-time graphic curves can be displayed during execution.

- With reservation startup and shutdown functions.

- Date and time adjustment function.

- Self-learning function for hast test chamber maintenance tips.

- Key and screen lock function.

Power supply conditions

AC220V FireWire + ZeroWire + Protective EarthWire. The user must set up an air or power switch of the right size for the equipment at the site. The switch must be separate from using the equipment..

Specimen Restrictions of hast test chamber

This hast test equipment prohibits:

- Testing or storage of specimens of flammable, explosive, or volatile substances.

- Testing or storage of corrosive substances.

- Testing or storage of specimens with strong electromagnetic emission sources.

Selected Components of Climatic Test Chamber

The system has intelligent protection control. It uses imported controls. Each component is carefully selected to get better test results.

- Pot body(SUS316) Taiwan

- Safety valve UK

- Pressure switch Japan

- Pneumatic (electromagnetic) valve Taiwan

- Fan Italy

- Motor Taiwan

- Shaft disk module Taiwan

- Pressure-resistant piping components Japan

- Electricity leakage circuit breaker Japan

- Transformer Taiwan

- SSR module Taiwan

- Controller system Hardware import, software self-developed

Hast test Chambers Meet the following standards

IEC60068-2-66; JESD22-A102-C; JESD22-A110-B; JESD22-A118; GB/T 2423.40-1997

FAQ About HAST Chamber

HAST testing is a highly accelerated stress test methodology used to assess the reliability of chips by simulating the operating conditions of chips in a high temperature and high humidity environment to accelerate the aging and failure process.

- Evaluate the stability of the chip in a high temperature and high humidity environment to ensure that the chip can work stably for a long time in a harsh application environment;

- To detect problems that may be caused by high temperature and high humidity, such as solder rupture or metal wire breakage due to thermal expansion and electrical connection problems caused by corrosion;

- Verify the reliability of the chip to provide manufacturers and customers with reliable product performance data.

In HAST testing, the test holder is the key component that connects the chip to the test equipment. It transmits electrical signals to the chip and transmits the test results back to the test equipment.The role of the test bench is to provide a reliable and stable interface to ensure normal communication between the chip and the test equipment and to ensure the accuracy and consistency of the test data.

- First of all, high temperature and high humidity are environments that test stands must be able to withstand. In HAST testing, the temperature is usually between 100°C and 150°C, and the humidity is as high as 85% to 95%. Therefore, test stands need to be able to withstand high temperatures and humidity to ensure their reliability. The choice of materials and the design of the structure of the test holder must take these factors into account to ensure that it does not fail or affect the test results during the test process.

- Secondly, the test holder must also provide good electrical performance. It should ensure good signal transmission and low resistance connections to ensure accurate communication between the chip and the test equipment. During the design and manufacturing process, it is essential to control and test the electrical characteristics of the test holder, including contact resistance, insertion loss, and signal amplitude.

- Finally, the design of the test holder should also match the requirements of the chip’s package and test equipment. Different types of chips have different package forms, such as die, QFN, BGA and so on. The test bench needs to make a corresponding design just according to the different packages of the chip.

- Routine assessment of product reliability

Accelerated assessment of product reliability through temperature, humidity, bias and other stresses. - It dramatically reduces product development cycles compared to traditional temperature and humidity testing.

HAST test temperature is usually higher than 105 ℃, in the humidity of the environment will produce a greater pressure, thus accelerating the moisture into the product interior, can be faster to make the device internal saturation, the first commonly used HAST test 96h instead of THB test 1000h, effectively shorten the test time.

High temperature and high humidity on the test samples, can constitute the water vapour adsorption, absorption and diffusion, the material in the inhalation of humidity expansion, performance deterioration, strength reduction, mechanical properties, adsorption of water vapour insulation materials caused by the decline in electrical properties. - Effectively improve the company’s test capacity and efficiency

Due to the reduction of test time, in the same time, more products can be temperature and humidity of the reliability of the test verification. According to the U.S. authority statistics, for electronic devices, humidity on the failure of the device accounts for about 19%. The main failure modes caused by humidity: corrosion, particle migration, diffusion, hydrolysis.

- High temperature step stress test

- Vibration step stress test

- Comprehensive stress test

- Low temperature step stress test

- Rapid thermal cycling test

- Working stress test

HAST Weathering Test is widely used for accelerated weathering life testing of products. For example, EVA, connectors, photovoltaic modules, polymer materials, circuit boards, semiconductors, magnetic materials, integrated circuits and other products. To reduce the time for life testing of a system or product and accelerate the test process. Accelerated life testing requires additional operational and environmental stress. Users rely on the test to analyze the wear and tear and length of service life of mechanical and electronic components, as well as determine the causes of increased failure rates.

HAST highly accelerated aging tester is a kind of test equipment used to simulate the aging of products under high temperature and high humidity environments. HAST stands for Highly Accelerated Stress Test. The tester uses high temperature and high humidity to speed up the aging of products. This helps find problems that may occur in long-term use. It also guides product design and improvement. We usually use the HAST tester for product testing. It’s used in electronics, optoelectronics, and other industries. These include the chemical, automotive, and aerospace fields.

The HAST test is a highly accelerated reliability test for electronic components. It’s based on temperature and humidity. Its full name is Highly Accelerated Temperature and Humidity Stress Test. In semiconductor devices, PCBs, solar energy, display panels, and other products, the highly accelerated aging test has become a standard high temperature and high humidity test. The aging test has become the standard as a fast and effective alternative to standard high temperature and high humidity tests (e.g., 85C/85%RH-1000 hours) alternative program.

The installation process for highly accelerated pressure test chambers involves a number of steps and it is vital to ensure safety and effectiveness.

Determining the ultimate stress level: Firstly, the ultimate stress level of the test specimen needs to be determined. This is the basis of the test, as if the sample does not fail when this ultimate stress is reached, the test can be stopped to avoid unnecessary damage.

Installation of the sample: The test product is installed in the highly accelerated life test chamber and the necessary electrical connections, signal input/output connections, monitoring equipment connections, etc. are made. Use sensors (e.g. temperature sensors, accelerometers, etc.) to monitor the stress levels applied to the test product. It is important that the various connections should be able to withstand the stresses applied during the test.

Initialisation test: Prior to formal testing, the subject product is functionally tested to ensure that it is working properly. The monitoring equipment also needs to be tested to ensure that it functions properly. Cables, etc., connected to the product under test also need to be checked to ensure their integrity and proper functioning under high stress (e.g., high air flow).

Increasing the test stress: Gradually increase the stress to the specified stress level. If the product under test is continuously monitored, the stress level can be continuously increased. If the product is not continuously monitored, the stress level is increased gradually to ensure that the product is stabilised at each stress level before conducting functional tests to collect information on possible failures.

Data analysis and report writing: After testing is completed, data is collected and samples are evaluated to analyse changes in performance under extreme conditions. A detailed report is prepared based on the test results, summarising the product’s performance and possible problems.

The entire installation and testing process needs to be carried out in strict accordance with the operating procedures to ensure safety and achieve the purpose of the test. In addition, for different types of test chambers (e.g. PCT High Temperature Accelerated Aging Tester, HAST Accelerated Life Tester, etc.), the operation methods and precautions are different, so the corresponding operation manuals should be read and understood in detail before actual operation.

The setup of a highly accelerated stress chamber includes sample preparation, setting parameters, initiating the test, analysing the data and writing the report.

Sample Preparation: First, the sample to be tested is placed in a specific location within the chamber. This step ensures that the sample can be accurately tested and that the results are not compromised by improper placement.

Setting parameters: The temperature, pressure, humidity and other parameters of the chamber are set according to the test requirements. This step needs to be adjusted according to the specific test requirements to ensure that the test conditions can simulate the extreme conditions of the actual use of the environment.

Start the test: open the test chamber, according to the set conditions for testing. This step is the core of the entire testing process, and it is necessary to ensure that all settings are correct in order to obtain accurate test results.

Data analysis: Once the test is complete, data is collected and the samples are evaluated to analyse the change in performance under extreme conditions. This step requires a detailed analysis of the test data to assess whether the samples are performing as expected.

Report Writing: A detailed report is prepared based on the test results, summarising the product’s performance and possible problems. The report should record the testing process, results and conclusions in detail to provide reference for subsequent product improvement.

Through the above steps, you can effectively set up and use the High Accelerated Pressure Test Chamber for testing to ensure the accuracy and reliability of the test results.

The installation process of a highly accelerated stress chamber involves several steps to ensure that the chamber will operate correctly and safely while protecting the test specimen from damage. The following are the main steps involved in the installation of a HAPT chamber:

Sample Preparation and Installation: Firstly, the sample to be tested is placed in a specific location within the chamber. This step ensures that the sample is securely mounted in the chamber and facilitates subsequent data collection and analysis.

Setting parameters: The temperature, pressure, humidity and other parameters of the chamber are set according to the test requirements. The setting of these parameters directly affects the test conditions and results, so they need to be set precisely according to the specific test requirements.

Electrical Connection and Signal Input/Output: Make the necessary electrical connections, signal input/output connections, and monitoring equipment connections. This step ensures that the test chamber is able to function properly and that data from the test process can be monitored and recorded in real time.

Monitoring with Sensors: Sensors (e.g., temperature sensors, accelerometers, etc.) are used to monitor the stress levels applied to the product under test. These sensors can monitor the environmental parameters inside the chamber in real time, ensuring consistent and controllable test conditions.

Initialisation test: The test product is functionally tested prior to the HALT test and the monitoring equipment needs to be tested to ensure that it is functioning correctly. This step is to ensure that the test chamber and monitoring equipment work properly before the start of the formal test to avoid problems during the test.

Increase Test Stress: Gradually increase the test stress to the specified stress level while performing functional tests to gather information about possible failures. This step is the core part of the test, where the stress level is gradually increased to simulate various extreme conditions in actual use, in order to assess the performance and reliability of the samples.

Data analysis and report writing: Once the testing is complete, data is collected and the samples are evaluated to analyse the changes in their performance under extreme conditions. A detailed report is prepared based on the test results, summarising the product’s performance and possible problems.

By following these steps, you can ensure that the High Accelerated Pressure Test Chamber is installed and used correctly, so that product performance and reliability testing can be carried out effectively.

The following steps should be followed when selecting a high pressure accelerated aging tester:

Define the test requirements: first, you need to define your test requirements, including the type of product to be tested, the required temperature range, humidity requirements, pressure conditions, etc.. These factors will directly affect the specifications and performance of the selected equipment.

Focus on performance parameters: the performance parameters of the high pressure accelerated aging tester is an important indicator of its performance. Need to pay attention to the temperature control accuracy, humidity control accuracy, pressure stability and other key parameters, these parameters will directly affect the accuracy and reliability of the test results. In addition, the heating speed, cooling speed and volume size are also factors to be considered, which will determine the testing efficiency and applicability of the equipment.

Examine the quality and after-sales service: the quality of the equipment is to ensure the accuracy and reliability of the test results of the premise, so you need to pay attention to the equipment’s manufacturing process, the choice of materials and brand reputation and other aspects. At the same time, after-sales service is not to be ignored, good after-sales service can provide timely technical support and solutions for the use of the process.

Comparison of price and cost-effective: price is an important factor to consider in the purchase process, but not the only factor. When comparing the price, you need to combine the performance of the equipment, quality and after-sales service and other factors for a comprehensive assessment, choose a cost-effective products.

Understand the difference between PCT and HAST tester: PCT (Pressure Cooker Test) and HAST (Highly Accelerated Stress Test) are two different high pressure accelerated aging test chambers, which are significantly different in terms of the test environment, test purpose, test time and results, test samples, test principles as well as the equipment and characteristics, etc. They have significant differences in terms of test environment, test purpose and results, test samples, test principles and equipment and characteristics. Understanding these differences will help you to choose the right tester according to your specific product characteristics and testing needs.

Through the above steps, you can be more clear about your needs, so that you can purchase a high-pressure accelerated weathering tester that meets your testing requirements.

Uhast refers to temperature and humidity unbiased highly accelerated stress testing, which determines the reliability of devices under high temperature and high humidity conditions without applying bias to the device.