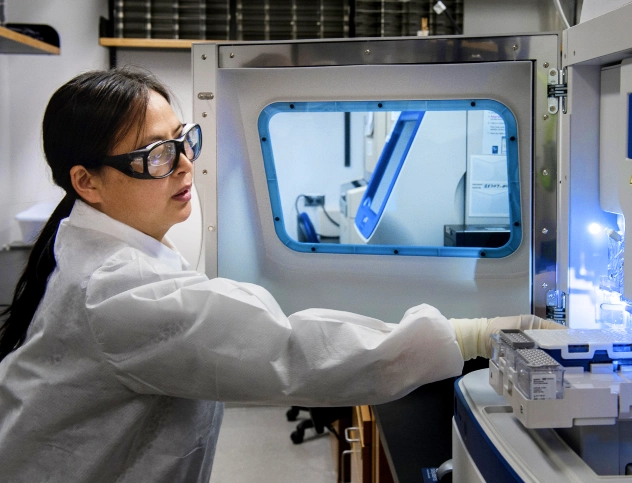

The AtmoExplorer Chamber offers cutting-edge material testing for diverse sectors. This guide explores the features and stresses the need for regular maintenance and professional help to keep it working well.

With the correct maintenance schedules and professional maintenance, your AtmoExplorer Chamber will continue to produce excellent results for many years.

Understanding the AtmoExplorer T & H Chamber

The AtmoExplorer Chamber performs meticulous materials tests under various conditions. Its array of tests and applications showcases its central role in diverse fields.

Tests Types:

The AtmoExplorer’s capabilities extend to a broad array of tests, offering detailed insights on:

- Heat Resistance: Exposes materials to high temperatures to check for expansion or melting.

- Cold Resistance: Simulates freezing to test material brittleness or flexibility loss.

- Dry Resistance: Checks how materials respond in moisture-free environments, ensuring durability.

- Wet Resistance: Tests for issues like corrosion or mold in humid conditions.

Real World Application:

The AtmoExplorer presents quality assurance across diverse industries, including:

- Electronics: The chamber tests environments for smartphones, wearables, and server components.

- Communication Devices: AtmoExplorer checks the reliability of radios and satellite phones in extreme conditions.

- Food Products: It evaluates food quality under various storage and transport conditions.

- Aerospace Products: The chamber ensures materials withstand space’s extremes, from cold to re-entry heat.

Why Maintenance is Crucial

Testing equipment, like the AtmoExplorer, plays a pivotal role in research and manufacturing. Its upkeep directly affects results, product quality, and overall safety.

Science relies on repeatability to ensure consistent outcomes. With a well-maintained chamber, uniform results are guaranteed, and consistent settings streamline the data analysis process.

Reliable testing outputs are crucial for making decisions about design changes and market introductions. Trust in a meticulously maintained chamber underpins and strengthens these pivotal choices.

Lifespan Extension

Investing in the AtmoExplorer represents a considerable commitment. Through routine checks and proactive repairs, one can prevent major breakdowns and extend the machine’s lifespan. Regular maintenance not only ensures accuracy. It also proves cost-effective by averting expensive replacements.

Safety & Prevention

Regular maintenance curbs sensor drift, ensuring accuracy and avoiding misleading results. Incorrect data can undermine product trust, potentially leading to real-world failures. We recommend prioritizing maintenance to mitigate the costly and trust-diminishing effects of product recalls.

Develop a Maintenance Routine for Accuracy

Maintenance of the AtmoExplorer is paramount, safeguarding accuracy, longevity, and trust in products. A proactive approach to upkeep translates to consistent results, extended equipment life, and reduced risks.

General Maintenance Tips for the AtmoExplorer Chamber

The AtmoExplorer Chamber is a high-tech solution that outputs accurate data for analysis. It needs consistent maintenance for accurate and reliable results from this chamber. Here is a comprehensive guide to ensure the longevity and precision of the AtmoExplorer.

Regular Cleaning

Environmental contaminants can drastically influence testing outcomes. Use suitable solutions and lint-free cloths to wipe the chamber’s interior for accurate simulations.

A clean exterior is not merely cosmetic. It reinforces insulation and supports the efficiency of the chamber’s temperature systems. Use soapy water to clean, wipe down with clean water, and then dry with a lint-free cloth.

It is useful to ensure the surrounding area is clean. This lowers the potential for contaminants to enter the chamber.

Sensor Checks

The chamber’s sensors are its core components. It is essential to perform regular tests to ensure reliable functionality under diverse conditions. For sensor reliability, compare readings with precision to set standards.

Seal Inspection

A chamber’s seal is vital for precise simulations. Routine inspections should highlight wear or damage, prompting timely replacements. Consistent pressure checks can preemptively detect faulty seals, safeguarding accurate results.

Calibration

Accuracy is the chamber’s cornerstone. Consistent calibrations align sensors and controls to industry standards. Especially after significant repairs, recalibration integrates updated parts seamlessly.

Humidifier Maintenance

Regularly replacing a humidifier’s water storage is essential. Doing so monthly ensures clean water and prevents blockages. This simple routine boosts the machine’s efficiency and lifespan, providing a healthier environment.

General Maintenance as Protection for Your Investment

With laboratory equipment recognized as a significant investment, it is vital to ensure longevity and accuracy. Accurate equipment provides your business with the competitive edge needed to succeed in your market.

Recognizing the AtmoExplorer Chamber’s Wear and Tear

Even the robust machinery of the AtmoExplorer Chamber isn’t exempt from wear and tear. Finding early wear signs can enhance efficiency and prevent costly repairs. Here’s a concise guide on the signs to watch out for.

Unusual Operational Sounds

Operators know the chamber’s typical operational sounds. Any deviations from this norm warrant immediate attention. Grinding noises or clicks might suggest internal component fatigue or electrical issues.

Specifically, grinding can hint at fan or motor troubles. Clicks may hint at relay switch malfunctions. Immediate action ensures the chamber’s longevity and accuracy.

Erratic Readings

Consistent data from the chamber is vital for accurate results. Any deviations should raise immediate concerns. Oscillating temperature or humidity hints at sensor issues or calibration needs.

A chamber’s adaptability is equally crucial. Delays in adapting to new settings are concerning. Such lags might suggest problems with controls or sensors.

Visible Component Wear

The chamber’s physical state offers valuable insights into its condition. Seals, essential for controlling the environment, should be inspected for wear or damage. Cracked or deteriorated seals can affect chamber functions.

Other external components, like knobs, are also indicative. If these parts show resistance or do not operate smoothly, it may be a precursor to larger issues.

Water leaks from pipes demonstrate potential blockages. Contact your maintenance supplier for support.

Operational Interruptions

Consistent operation is expected of the chamber. However, unexpected halts during tests might suggest issues with power, systems, or overheating components.

The in-built diagnostic tools make it crucial to pay attention to error messages that warn of underlying problems.

The Value of Regular Monitoring

Regular maintenance of the AtmoExplorer Chamber is pivotal for ensuring its longevity and accuracy. Noticing wear signs early can prevent costly repairs and downtime.

Professional Intervention for the AtmoExplorer Chamber

The AtmoExplorer Chamber, with its intricate design and advanced electronics, demands specialized care. Though routine in-house checks are crucial, sometimes only a professional’s expertise suffices. Here is an overview of when to call for professional support.

Deciphering Unusual Malfunctions

Deciphering unusual malfunctions in the AtmoExplorer can challenge even seasoned technicians. Mysterious behaviors not detailed in the manual signal a need for specialist consultation. These obscure symptoms might hint at underlying problems.

Persistent glitches post-intervention raises concerns. They could suggest misdiagnosis or deeper complications. In such cases, expert insight is invaluable.

Major Repairs & Calibration

Major repairs in the AtmoExplorer demand specialized expertise. Trained professionals should change key components, like heating or cooling systems. After extensive fixes, recalibration by experts ensures precision restoration.

Upholding Originality in Parts

Using original parts for the AtmoExplorer is essential for its optimal performance. Tailor-made for specific models, they promise seamless integration and peak function.

Turning to third-party components can jeopardize the manufacturer’s warranty. Genuine parts, built to exact standards, ensure longevity, and uphold the equipment’s superior functionality.

Prioritizing Expertise and Authenticity

The AtmoExplorer Chamber depends on genuine parts and expert help to perform its best and stay in good condition. Seeking expertise and using original components ensures reliability and safeguards your investment.

Conclusion

The AtmoExplorer Chamber plays a central role in testing materials under diverse conditions. Proper maintenance guarantees its longevity, ensuring reliable and precise outcomes. Recognizing early signs of wear and getting expert support, when necessary, keeps it performing at its best.

For those using the AtmoExplorer, it is vital to prioritize its care. Stay proactive with maintenance checks and always opt for genuine replacement parts. Secure your investment and ensure accurate results for years to come.

For a deeper dive into maintenance procedures and best practices, refer to: User-Manual-CV340-ATMOEXPLORER-TEMPERATURE-HUMIDITY-CHAMBER

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]