The light source of the UV chamber is mainly fluorescent UV lamps. Testing of materials by simulating ultraviolet radiation and condensation in sunlight. To make the UV test chamber work better, long-term good condition. So it is necessary to care for and maintain the UV aging test chamber.

UV aging test chamber safety operation norms and cleaning and maintenance methods

Test Chamber Safety Operation Norms:

- Non-professionals should not operate this equipment. It is best to have a professional technician operate the test box.

- Because ultraviolet radiation on the personnel has a strong hazard. Ultraviolet radiation is particularly harmful to the eyes. So the operator should cut exposure to ultraviolet radiation. The contact time should be <1 min. The operator should wear goggles and sheath during operation.

- Do not look directly at lit lamps at close range.

- Try to avoid bare skin under the lighted lamp.

- During the test, cut the number of times and duration of opening the door.

- Prohibit chemical contact with this UV aging test chamber. The UV chamber should not be close to explosives and combustibles.

- The user cannot troubleshoot the UV light chamber alone.Users should contact the manufacturer immediately. Or find a technician to repair it, do not disassemble it.

- Prohibit the setting of the temperature exceeds the specified largest temperature

- Each time before starting to check the circuit control system. The user must properly connect the power cord and grounding according to specifications.

- Users need to check the over-temperature protector, whether it has been set. Factory adjusted by the manufacturer at the time of shipment, generally do not adjust.

- Upon completion of the test, the operator needs to disconnect all power sources.

UV Light Simulation Accelerated Weathering Aging Test Chamber Normative Maintenance Methods:

- During the operation of the equipment, make sure to maintain enough water supply. In non-operating conditions, disconnect the power supply and keep it dry.

- At the end of the test, the operator should drain the tester. The operator shall also dry the workshop and the box.

- To avoid dust intrusion, remember to put the plastic outer cover on after use.

- The user must not forcefully touch the sensing devices in the work chamber.Also, avoid external impact on the box.

- It is better to place the UV test chamber in a well-ventilated place. Users should install ventilation fans to keep the room ventilated.Do not install in dusty places.

- Long-term non-use or re-use must check the water supply, power supply, and components. Determine that there is no error before starting the equipment for the test.

- The user should install a wastewater drainage system for the UV chamber.

- Monthly calibration lamp irradiance to meet the requirements.

- Users should install ventilation fans in the laboratory to keep the room ventilated.

- Spray test should pay attention to observing the water level of the water tank. When the water level is too low, users should replenish pure water in time.

UV accelerated aging chamber Daily Cleaning Work:

- Clean the studio every month and clean the scale from the aluminum plate under the lamp.

- Clean the surface of the instrument dust, and debris.

- After use, if there is dust on the plastic cover, the user should remove it promptly. In order to avoid dust intrusion into the instrument, the user should keep the appearance of the casing neat and tidy.

- The user should remove the sample after each test.Clean the inside of the UV aging test chamber.

Operating and Maintenance Precautions:

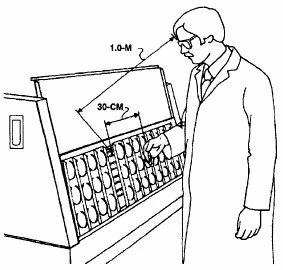

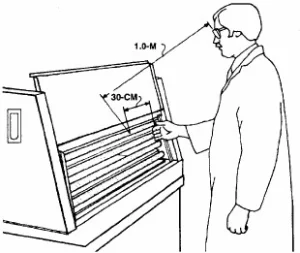

- With one sample rack removed and hands 50 mm from the lamp source, allow 1 minute of exposure per day.

2. With one sample rack removed and hands 30 cm from the lamp: allow 6 minutes of exposure per day. One meter from the lamp with face: Allow 18 minutes of exposure.

3. With all racks removed and hands 30 cm from the lamp: allow 2 minutes of exposure daily. Face 1 meter from the lamp: Allow 6 minutes of exposure.

UV Lamp replacement:

Irradiation intensity affects lamp life. The higher the irradiation intensity, the shorter the life. The largest irradiation lasts about 1000 hours and normal irradiation lasts longer. The user needs to replace the lamp once a year. Whether or not the light intensity setting remains the same.Because condensation and air movement can cause the lamps to become dirty. This causes the spectral distribution to be affected.

UV accelerated aging chamber Installation place

To maintain and ease heat dissipation of the environmental chamber. Installation of the climatic chamber should pay attention to the following matters:

- There should be enough space between the equipment and the wall or other equipment.

- To better perform the function of the test chambers. Should choose a perennial temperature of 21 ℃ ~ 27 ℃, relative humidity is not greater than 85% of the place.

- You should choose a place where the ambient temperature changes are small.

- The UV weathering tester should be placed on a level floor. The user may use a level to determine the level on the floor.

- Users should choose to install the UV test chamber in a well-ventilated place without direct sunlight.

- The UV chamber should not be close to explosives and high-temperature heat sources.

- UV aging tester can not be placed in a dusty place.

UV aging test chamber Common Fault Analysis

1. UV lamps are not working.

When in use, the UV lamp will appear the light will be bright for a while and not bright. This is because UV aging testers generally use electronic ballasts. Which are wired as jacks. To avoid such problems, users can pay attention to the details of the production process. This leads to the lamp corner line, and electronic ballast connection is not secure. It is prone to problems such as poor contact and gap disconnection during future use.

2. The ends of the UV lamp are blackened.

The material used for the filaments at both ends of the lamp is tungsten. When the light is turned on, the temperature of the lamp does not exceed 3000℃. The melting point of tungsten is 3410°C, so the filament will not melt. Only sublimation will occur. After sublimation, tungsten will sublimate into solid tungsten when it meets the wall of the tube. Then, it makes the two ends of the tube black. After the lamp is blackened, it needs to be replaced with a new one. Frequent starting and shutting down of the lamps tends to shorten the life of the lamps. It is recommended not to turn off the lamp for at least 3 hours after it is lit up.

3. Rusting through the UV water tank.

The sink holds water for heating to simulate a condensing environment at night. The sink is made of stainless steel. If not, add deionized water as required, but add tap water. This will cause the sink to corrode by substances formed by water heating. This will cause the sink to rust until the sink rusts through.

4. Corrosion of heating tube

The material used for the heating tube is stainless steel, filled with magnesium powder. If the water used in the heating tube is not deionized. And the heating tube has been working in tap water for a long time for heating. This will corrode the stainless steel on the surface of the heater, and further rust will appear.

5. Gauges in UV weathering test chambers are prone to failure.

Instruments are mounted at the top of the machine, so they are prone to problems. When the heating works, if the laboratory does not install air conditioning. The instrument will be subject to long-term high-temperature ravages if the heat is upward. Sometimes, a test is done for several days or even weeks. These can lead to temperatures up to 60°C. Instruments are prone to malfunction in hot environments.

UV accelerated aging chamber Prohibited test items

Explosives

- Explosive nitrates. For example, nitrocellulose, nitroglycerin, and so on.

- Explosive nitro compounds. Examples include trinitrophenol, trinitrobenzene, and trinitrotoluene.

- Organic peroxides. Examples include methyl ethyl ketone peroxide, peracetic acid, and benzoyl peroxide.

Combustibles

Spontaneous combustibles: metals: “lithium”, “potassium”, and “sodium”.

Celluloid: Sodium bisulfite, aluminum powder, calcium carbide, magnesium powder.

Oxidizing Properties

- Chlorates. Examples include potassium chlorate, ammonium chlorate, and sodium chlorate.

- Potassium peroxide, sodium peroxide, ammonium peroxide, and other peroxide salts.

- Inorganic peroxides. Examples include potassium peroxide, barium peroxide, and sodium peroxide.

- Nitrates. Examples include sodium nitrate and potassium nitrate.

- Hypochlorites, such as potassium hypochlorite

- Chlorites, such as sodium chlorite.

Flammables

- Substances with a flash point not exceeding -30°C. For example, carbon disulfide, gasoline, and ether.

- Substances with a flash point above -30°C and less than 0°C. Examples include benzene, ethylene oxide, ordinary ethane, and acetone.

- Methanol, ethanol, amyl acetate, and other substances with a flash point above 0°C but less than 30°C.

- Kerosene and other substances whose ignition points are above 30℃ and below 65℃.

Combustible gases

Hydrogen, acetylene, ethylene, methane, butane, and other gases may burn at a temperature of 15°C at 1 atm. pressure.

Conclusion

The UV chamber uses fluorescent UV lamps. This kind of lamp can simulate the UV section spectrum in sunlight. Combined with temperature control and other devices to simulate condensation and other factors. Meanwhile, there is a Simultaneous synergy between UV light and moisture. The single light (moisture) resistance of the material weakened or invalidated. Thus, it is used for evaluating the weather resistance of materials. Want to make the UV aging test chamber more durable? Maintenance work is essential.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]