Introduction

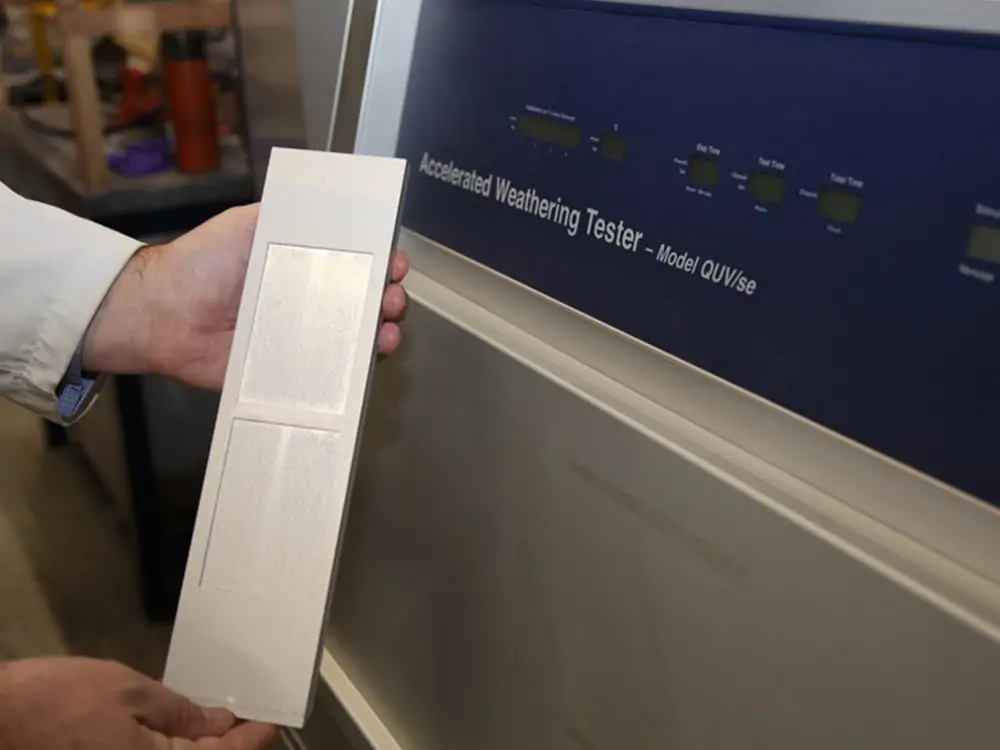

In the realm of materials science, accelerated weathering tests stand as essential tools. They allow us to understand how various materials and outdoor machinery endure damage or exposure due to moisture and sunlight. These tests encompass materials such as wood, metals, polymers, coatings, textiles, adhesives, and construction materials, offering valuable insights into their resistance to environmental stressors. Weathering can lead to cracking, brittleness, strength reduction, oxidation, and other detrimental effects, including hazing, gloss loss, and color changes.

These tests play a pivotal role in diverse applications and industries, particularly in environments where weathering is a critical concern. Notably, they find utility in extreme weathering and corrosion-prone areas, where test panels expose materials to severe conditions. This process uncovers natural acceleration factors, addressing concerns regarding artificial weathering simulations.

Exploring Types of Material Damage from Weathering

Material degradation due to environmental exposure can manifest in several ways, including significant color loss, changes, and yellowing. To mitigate the effects of weathering and ensure regulatory compliance, standardized tests have been established, including:

•Humidity Test (Water Fog)

The humidity test, often referred to as the water fog test, is a widely accepted method for accelerated weathering testing. It subjects materials or products to controlled humidity levels within a chamber. This test replicates exposure to high humidity conditions, which can lead to moisture-related issues such as swelling, warping, and mold growth.

•Assessing Paint and Coating Durability

Paints and coatings are highly susceptible to environmental stressors, including UV radiation, moisture, and temperature fluctuations. Accelerated weathering tests specific to paints and coatings evaluate their resistance to these factors, assessing properties like adhesion, color stability, and gloss retention.

•UV/Fluorescent Testing

Understanding how materials and products respond to UV radiation is crucial since it is a major contributor to weathering damage. UV fluorescent testing involves exposing samples to UV light sources that replicate natural sunlight. This test facilitates the evaluation of UV-induced effects, such as color fading, embrittlement, and surface degradation.

•CASS Test (Copper-Accelerated Acetic Acid Salt)

The CASS test is particularly relevant when assessing the corrosion resistance of materials, especially metals. It involves exposing samples to a corrosive environment containing acetic acid and copper chloride salt. This test accelerates corrosion processes and aids in predicting a material’s susceptibility to corrosion in harsh conditions.

•Fog Testing (Salt Spray)

Salt spray testing is another widely used accelerated weathering test to evaluate the corrosion resistance of materials and coatings. During this test, samples are exposed to a saltwater mist, simulating the corrosive effects of salt-laden air often found in coastal or industrial environments. The test assesses a material’s ability to withstand salt-induced corrosion.

Benefits of Accelerated Weathering Testing

Accelerated weathering tests offer numerous advantages that are crucial for product development and feature enhancement. These assessments are broadly categorized into two approaches:

Natural Accelerated Weathering:

This method accelerates the weathering process using specialized environmental chambers, frequently employed at an industrial scale. Samples undergo conditions that replicate natural weathering, including exposure to UV radiation, moisture, and temperature variations. This approach enables researchers to predict material behavior over extended durations.

Laboratory-Accelerated Weathering:

Specialized weathering chambers equipped with tailored lamps are employed to simulate environmental degradation resulting from solar radiation. These chambers provide controlled exposure to UV and visible light, enabling precise testing of materials’ UV resistance.

Methods for Accelerated Weathering Testing

Simulating Solar Radiation

This test simulates the effects of solar radiation on materials, emphasizing the development of products that remain durable regardless of environmental conditions. Extended exposure to sunlight can be particularly detrimental to materials, necessitating an assessment of their UV radiation resistance.

Xenon Arc Test

The Xenon Arc Test focuses on the weathering effects of both indoor and outdoor exposure, making it especially valuable for coatings, paints, plastic, rubber, and building materials. It involves exposing samples to xenon arc lamps, faithfully replicating sunlight, encompassing UV and visible light.

Ultraviolet (UV) Exposure Test

The UV exposure test recreates environmental weathering conditions using fluorescent UV lamps. It assesses various effects of UV radiation, including color changes, brittleness, and performance degradation. UV exposure can lead to surface degradation, mechanical property loss, and alterations in material appearance.

Carbon Arc Test

The carbon arc test evaluates a material’s resistance to sunlight, heat, and moisture, encompassing radiation types such as UV, visible, and infrared radiation. This comprehensive test delves into the optical, mechanical, and electrical properties of materials. It is especially relevant for materials exposed to outdoor environments characterized by high levels of UV radiation.

Additional Accelerated Weathering Test Methods

Paint and Coating Testing

This evaluation method involves exposing paints and coatings to indoor and outdoor environments. It helps manufacturers understand how these materials will perform over time when subjected to weathering conditions, including UV radiation, moisture, and temperature fluctuations.

Salt Spray, Salt Fog, and Corrosion Testing

Salt spray, salt fog, and corrosion testing assess the resistance of materials and products, particularly fasteners and metallic components, to corrosion. The salt spray testing exposes samples to a corrosive saltwater mist, replicating the conditions found in coastal or industrial settings.

Sand and Dust Testing

Sand and dust testing simulates the effects of abrasive particles on machinery and equipment. These tests recreate conditions where fine sand particles, often around 150 microns in size, infiltrate crevices and components, potentially causing damage and malfunction.

Significance of Accelerated Weathering Testing

Accelerated weathering testing holds immense significance for several reasons:

- Assessing Corrosion Resistance:

These tests provide crucial insights into a product’s corrosion resistance, aiding manufacturers in selecting materials suitable for outdoor and challenging environments. - Predicting Material Behavior:

Weathering conditions, including seasonal storms, natural disasters, humidity, moisture, and heat, can significantly impact materials. Accelerated weathering tests enable researchers to predict how materials will behave under these conditions. - Time Efficiency:

Accelerated weathering testing offers a time-efficient alternative to gathering data on material reactions over extended periods. This expedites product development and optimization. - Data Collection and Informed Decision-Making:

Researchers can systematically collect data on how each material, machine, or product reacts to various environmental factors. This data informs informed decisions and facilitates improvements. - Applications of Accelerated Weathering Testing

Accelerated weathering testers evaluate the weathering conditions and resistance of various materials. These materials include adhesives, automotive materials, roofing materials, paints and coatings, decking materials, automotive materials, and paint systems for protection.

Standards for Accelerated Weathering Testing

Numerous standards govern accelerated weathering tests, ensuring consistency and reliability in assessments. These standards encompass:

- AAMA 624:

This specification focuses on the testing performance and techniques for organic layers and supported profiles. It is particularly relevant for products like doors and windows. - AATCC TM186:

Concentrating on weather resistance, this standard involves the exposure of textile materials, including coatings and fabrics, to UV light and moisture in artificial laboratory settings. - ASTM C1257:

This standard addresses accelerated weathering for solvents and sealants, encompassing procedures for predicting UV-visible or non-visible radiation, moisture, cracking, color changes, and adhesion. - ASTM C1442:

Focused on sealants, this standard typically employs environmental weathering apparatus. It includes three lab procedures that concentrate on the effects of actinic radiation, moisture, heat, and adhesion. - ASTM C1501:

This standard method test for construction sealants employs either ultraviolet (UV) or xenon arc tests to describe how accelerated weathering procedures work over extended periods. These tests determine the coating or paint color stability for machines or buildings.

Conclusion

In conclusion, accelerated weathering tests serve as indispensable tools in the field of materials science. They enable us to assess how materials and machinery respond to environmental stressors, such as moisture and sunlight. These tests encompass various materials, ranging from wood and metals to coatings, textiles, and adhesives, offering insights into their durability and performance. Weathering can lead to detrimental effects, including cracking and color changes, making accelerated weathering testing a crucial step in product development.

Incorporating standardized testing methods, including those established by organizations like AAMA and ASTM, enhances the credibility and consistency of accelerated weathering assessments. These tests empower manufacturers to make informed decisions, optimize products, and ultimately deliver materials and machinery that can withstand the test of time and environmental stressors.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]