When a customer inquires about the xenon lamp aging test chamber, manufacturers will ask for some information. The first thing is about the intended location of use. Does this relate to the customer’s flooring and heat dissipation?

This relates to the xenon lamp weathering tester is suitable for air-cooled or water-cooled. These two although there is no difference in the use of function. But the structure and the same test conditions under the effect are different, as follows:

Structural Differences

Air-cooled xenon lamp aging test chamber

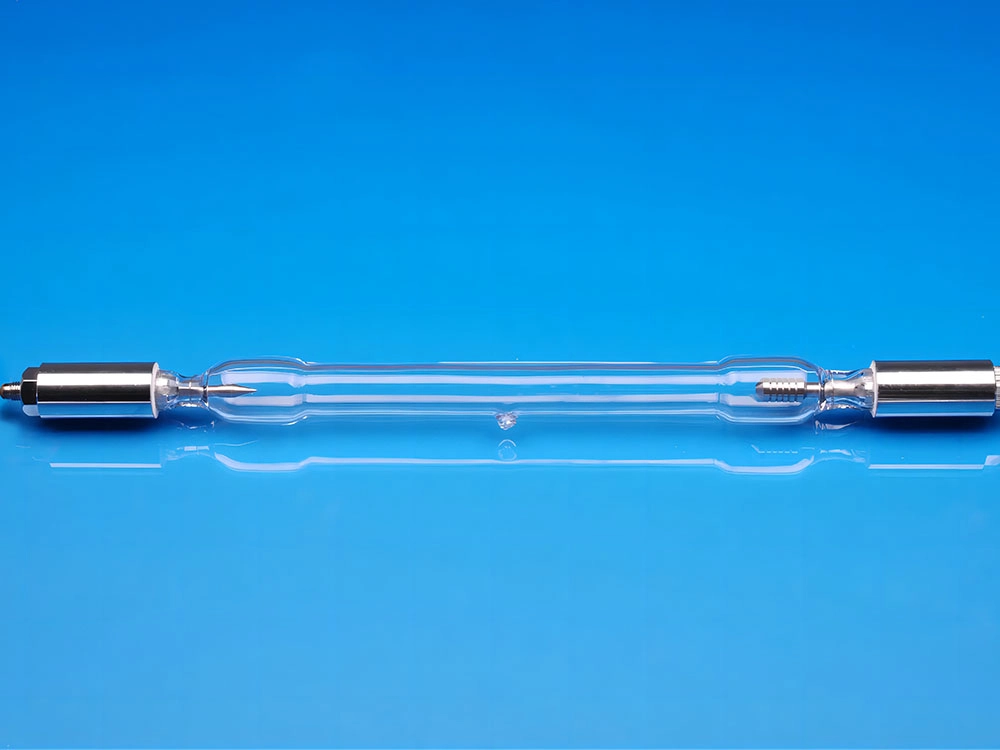

Air-cooled is a flat xenon lamp; the lamp is placed flat on top of the device, and there is a flat sample compartment below. It is easy to place some irregular products that cannot be sampled, but the test area is small. Install one or three air-cooled lamps in the test chamber. The test article is placed on the sample plate under the lamp for static radiation. This type of tester is called an “air-cooled xenon aging tester”. (The power of an air-cooled xenon lamp is lower than that of a water-cooled xenon lamp, typically about 1.8 kW.)

Three or more air-cooled lamps are often used to improve illumination. Due to the low power and low calorific value of water cooling in air-cooled xenon lamp chambers. So it is suitable for air-cooled circulation cooling. The structure of air-cooled xenon lamps is up-and-down static. So it can test any regular and irregular test items. They are widely used in automobiles, cosmetics, science and technology colleges.

Water-cooled xenon lamp aging test chamber

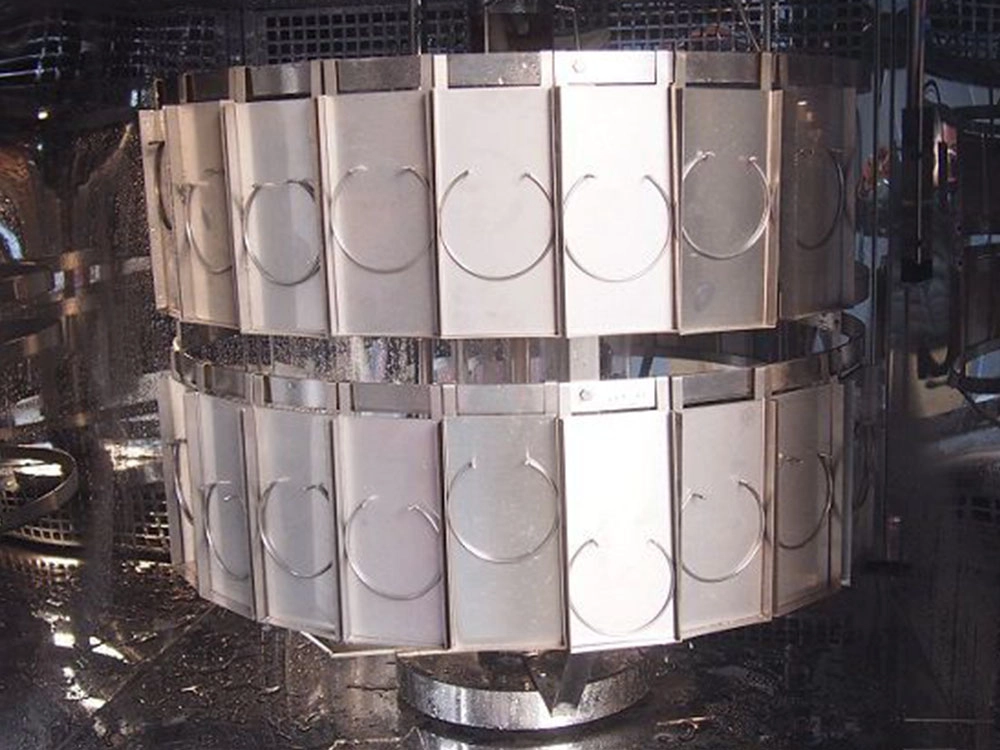

Water-cooled is a rotating drum xenon lamp, the lamp is installed in the firm direction. There is a rotating cage around the lamp. Which can rotate the product 360° for testing and irradiate a larger area. However, it is recommended to use it only if the sample to be tested can be sampled or sliced. Water-cooled xenon lamps are high power and only one water-cooled lamp is used in a test chamber. In the internal tank, the xenon lamp is placed vertically in the center of the instrument. It is surrounded by a filtration system. The specimen is mounted facing the light source. It rotates around the center like a conveyor belt. Due to the jig shape of the sample area, it is suitable for thin and regular specimens. Widely used in paint, coating, rubber, plastic, fabric, and other industries.

Lamp Power Difference

Air-cooled xenon lamps commonly used power 1500w/branch or 2500W/branch. Higher power is not suitable for air-cooled, water-cooled is better. Because air-cooled is easy to hang up. Water-cooled lamps have 4500W/branch or 6000W/branch. The volume affects the number of lamps. Water-cooled and air-cooled the same number of products, water-cooled lamps 1 can be. But air-cooled may be the least of 6 or even 7 ~ 8.

This also explains why there are different power lamps. Under what circumstances to use high-power lamps? That is, in the same wavelength, such as 420nm often do is often 1.1W/m2 and 1.2W/m2. However, the customer requests 1.5W/m2 then is to enhance the model.

Difference in Uniformity

Water cooling has better uniformity. The uniformity of a single lamp is good, but the uniformity of many lamps is not so good. Because there is no difference between lamp zones, etc.

Equipment Price Difference

Water-cooled than air-cooled xenon lamps cost about twice as much. Because air-cooled blowing air into the lamp to cool it. Water-cooled need to use water to let the lamp cool, the process requires more. Especially the treatment of water quality. Air is highly penetrating, water is not the same, and there will be impurities. This impurity will bring dirt. Thus, dealing with these problems leads to higher costs and more complex technology. Thus, dealing with these problems leads to higher costs and more complex technology.

Consumables Price Difference

The cost of consumables for air-cooling is higher than water-cooling. In the same area of the test object air-cooled lamps may use many. But the water-cooled lamp is enough for one.

Although a water-cooled lamp is about 2 times more expensive than an air-cooled one. But under the same test conditions, the air-cooled lamp may need 6 lamps or even 7~8 lamps. But water-cooled only one can be, so the cost of air-cooled late replacement lamps will be expensive.

Selection Differences

We are in the selection of air-cooled and water-cooled xenon lamp aging testers. All the wavelength requirements of air-cooled or water-cooled can be achieved.

Only for the test samples, it is recommended to choose.

If you want to put a lot of things or a large area of the recommended water-cooled. The area of water cooling is three times that of air cooling, but this is required for flakes or paint. Air cooling is recommended for small areas, and air cooling is recommended for irregular products.

Lamp difference

The air-cooled xenon lamp weathering tester adopts 3 imported lamps. Lamp power 1.8KW/branch. The effective service life of the lamp in the 1600h ~ 1800h or so.

The water-cooled xenon lamp weathering tester adopts 1 domestic lamp, lamp power 6KW/branch. the effective service life of the lamp is about 500h ~ 700h.

Lamp placement and protection system differences:

Air-cooled xenon lamp weathering tester 3 lamps installed side by side on the top of the box. The use of circulating air to protect the lamp.

A water-cooled xenon lamp weathering tester 1 lamp was installed in the center of the box. Using circulating water to protect the lamp.

Difference in radiation intensity:

- Air-cooled xenon lamp weathering test chamber:

Radiation intensity: ≤ 500W / ㎡, relatively more suitable for indoor products. - Water-cooled xenon lamp weathering tester:

Radiation intensity: ≤ 1120W ± 200W / ㎡, relatively suitable for outdoor products.

Air-cooled and water-cooled xenon lamp weathering tester sample frame structure differences:

The air-cooled xenon lamp weathering tester sample rack is a tray type. Sample tray size: 450mm × 720mm, It can be manually adjusted height. The sample rack and lamp distance: 230 ~ 280mm. The shape of the product is to be tested without requirements. As long as it can be placed on the sample tray.

The water-cooled xenon lamp weathering tester sample rack is a rotating drum type turntable type. It can be rotated 360 °, but the shape of the product under test requirements, must be a thin sheet. The standard sample size of 75mm × 150mm, and hung on the turntable for testing.

Difference in spray effect

Inside the air-cooled xenon weathering tester, the test specimen is placed on a flat sample tray. By tilting the sample 5° horizontally, the spray water is evenly applied to the surface of the sample. At the same time, because the sample is placed close to horizontal, the water does not run off quickly. The sample remains moist throughout the entire humidity cycle.

The water-cooled xenon weathering tester has a spray bar and nozzles. Water is sprayed on the rotating sample as it passes by. The sample remains wet for approximately 3s of every minute. Some chambers are fitted with 2 shower bars that spray water on the front and back of the sample at the same time. As the sample is placed vertically, the water runs off the surface very quickly. During the wet gap, the sample can dry out after turning away from the spray position.

Difference between xenon lamp filters

Air-cooled xenon lamp weathering tester:

- The light filter is used to filter out short and light ultraviolet and infrared light.

The power of air-cooled xenon lamps is lower than water-cooled lamps, around 1.8KW. Standard air-cooled xenon lamps are three or more lamps to increase the illuminance. Because the air-cooled xenon lamp box for water-cooled low power, low heat. It is suitable for air-cooled circulation cooling mode. The structure of the air-cooled xenon lamp is up and down static type. So for any regular and irregular test articles can be tested. It is widely used in automobiles, cosmetics, science and technology colleges and universities.

Water-cooled xenon lamp weathering tester:

- A light filter is used to remove short UV and IR light.

The wavelength of the water-cooled xenon aging tester is ≤270 nm ~ infrared region. The lamp power is about 6KW, and the general working cycle of the test chamber is about one week.

In this non-stop work time, the xenon lamp issued by the heat is huge. If the heat is not dealt with on time. The xenon lamp will be damaged by overheating and the temperature will increase. This ultimately leads to inaccurate test results.

Thus, to effectively improve the test life of the lamp. Water-cooled xenon lamps take advantage of the good thermal conductivity of water. And adopt a water-circulation cooling method to cool down the lamp.

At the same time, to make the temperature inside the chamber uniform and controllable. The test chamber is specially equipped with a compressor. It is used to offset the high temperature brought about by the xenon lamp. It is worth mentioning that the xenon lamp aging chamber is generally not equipped with a heater.

Due to the high power of water-cooled xenon lamps, only one water-cooled lamp is used in a test chamber. Since the sample area is fixture-like. It is suitable for test articles with thin sheet-like rules. It is widely used in paint, coating, rubber, plastic, fabric, and other industries.

Water-cooled and air-cooled xenon lamp Aging test chamber advantages and disadvantages

Advantages and disadvantages of water-cooled xenon lamp weathering tester?

Advantage:

The lamp of water-cooled xenon lamp is installed in the middle of the equipment. It is installed vertically, and the turntable with samples rotates around the lamp. Its advantage is that each sample and the lamp distance are equal. It avoids the corner of the sample by the radiation degree is not enough defects. And it ensures that each sample gets the same irradiation intensity irradiation. It has a very good comparability.

Disadvantage:

The turntable-type installation equipment is relatively large. And the configuration of the pure water system, and cold water equipment. So the price is relatively expensive. Besides, the use of consumables: water-cooled xenon lamps are also higher.

Air-cooled xenon lamp weathering test chamber advantages and disadvantages?

Advantage:

The air-cooled xenon lamp is mounted horizontally on top of the inner chamber. The sample holder is mounted in the middle of the inner chamber. The distance between the sample holder and the lamp can be adjusted according to the size of the sample. The advantages of the Xenon lamp are its simple structure and the large test space. It is suitable for testing undersized samples and is relatively affordable.

Disadvantage:

The distance between the sample and the lamp in the inner box is not equal. Or samples placed in the corners are exposed to weaker radiation. Thus, it is necessary to pause the test to adjust the sample placement.

Summary

Through the above comparison, the choice of air-cooled or water-cooled. The main consideration of the tester samples is regular. If the sample is regular and small size. Easy to take samples recommended water-cooled type. If the sample is irregular and the size is relatively large. Not good sampling, we recommend the use of air-cooled type.

Air-cooled and water-cooled xenon weathering tester have their own advantages and disadvantages. To choose a more suitable for their own products. Users in the buy can consider the test requirements, sample size, etc.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]