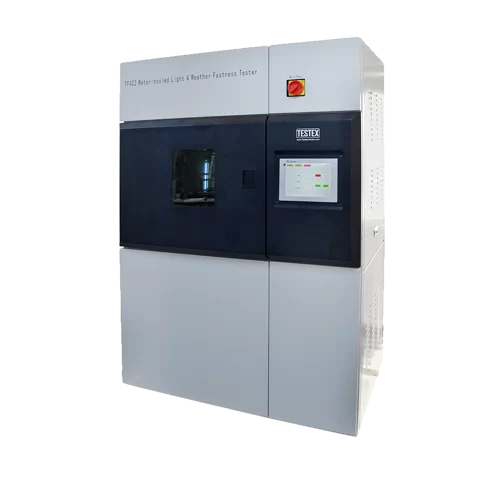

The Specification Of AtmoExplorer Temperature Humidity Chamber

Temperature range: -20°C~+150°C

Humidity range: 20-98%RH

Temperature and humidity control accuracy: ±0.5°C; ±3%RH

Temperature and humidity distribution uniformity: ±2°C; ±3%RH

Heating time: temperature to 100°C within 30 minutes

Cooling time: temperature down to -20°C within 60 minutes

Testable area: 500*750*600mm (D*W*H)

Various Sizes Can Be Customized: such as 80L, 150L, 225L, 408L, 800L, 1000L

ChiuVention Environmental Chamber Temperature And Humidity Control Accuracy

Temperature and humidity control precision: ±0.5°C; ±3%RH

Temperature and humidity uniformity: ±2°C; ±3.0%RH

Rapid Heating And Cooling Of The Environmental Test Chamber

When not loaded, the AtmoExplorer can heat from room temperature to 100°C in 30 minutes. It can also achieve cooling from room temperature to -20°C within 60 minutes.

ChiuVention Climate Chamber Has A Wide Range Of Applications

The temperature and humidity chamber can simulate high and low temperature. They can also simulate high and low humidity.

This temperature and humidity chamber tests temperature and humidity.The test chamber meets requirements in many fields and industries. These include electronics, materials research, medicine, automobiles, and food.

The Constant Temperature Humidity Chambers Operates Stably:

The heating element is made of spring-loaded Nichrome wire. Solenoid valve and other refrigeration auxiliary parts are used first-line brands. France imported “Taikang” full closed type high-efficiency compressor. Humidifier for stainless steel electric steam generator in the form of UL-type humidifier.

Functional Structure Of The Constant Temperature and Humidity Chamber:

7 inch large touch screen, easy to operate.

Built-in LED window lighting, easy to observe the sample.

Equipped with RS-232, USB interface, external computer copy data.

With reservation startup and shutdown function, key and screen lock function.

The program memory fails. The program will start and continue after power is restored.

Power

380V 50HZ 20A 3φ 4 wire

Weight

295kg

Dimension

225L 1330*940*1670mm (D*W*H)

Safety Protection Device Of Constant Temperature And Humidity test Chamber

Anti-burn switch, no fuse switch protection.

Short-term water shortage alarm and long-term water shortage shutdown protection.

Compressor high pressure protection, compressor overheating protection, compressor overcurrent protection.

ChiuVention Environmental test chamber After-sales service

- Free training of operators and maintenance personnel for customers (in our company or at the customer’s location).

- The whole machine warranty period: two years. Quarterly maintenance (quarterly in the province to the factory for regular maintenance, outside the province according to consultation)

- A complete maintenance service team provides the fastest and most professional maintenance services (1HR reply for repair reports, 24HR arrival at the factory, problem solving)

FAQ About Constant Temperature And Humidity Chamber

1. Poor air circulation

Poor air circulation inside the test box will affect the distribution of moisture, resulting in uneven humidity. The test box has poor sealing, which causes poor air circulation and prevents humidity from rising. The moisture-proof plate, sealing strips, and elastic contact parts contribute to this issue.

2. Monitoring control system failure

The test box humidity setting is inaccurate, or humidity sensor failure, monitoring, control software failure, etc., may lead to the test box humidity not going up. This is because when the monitoring and control system fails, the humidity inside the test box can not be monitored and adjusted in a timely manner.

3. Removal of incomplete reasons

If there is dust, moisture, or other contaminants in the test box, it will affect air circulation. This situation can lead to uneven humidity, preventing humidity from increasing. To prevent this, clean the test box promptly to maintain a clean and dry internal environment.

4. Humidifier failure

Test box humidifier failure, or humidifier and control system mismatch, will also lead to the test box humidity does not go up. Humidifier failure refers to the humidifier sensor, sprayer, and other parts being damaged or aging, so you need to contact the supplier to overhaul or replace the humidifier.

5. The ambient temperature is too low.

The ambient temperature of the test chamber is too low, which will also affect the rise of humidity. When the temperature difference between the inside and outside of the test box is too large, it will lead to insufficient atmospheric humidity, thus affecting the rise in humidity. At this time, it is necessary to increase the temperature inside the test box to enhance the rate of rise in humidity.

High-temperature Test:

The test chamber can test high temperatures up to 150 °C. If you need higher temperatures, customization is available upon request. This chamber is mainly used to assess how electronic products withstand high temperatures. Test the product’s aging in high-temperature environments to make sure it doesn’t change shape, become dry, or have other negative reactions.

Low-temperature Test:

It can also perform low-temperature tests, capable of reaching minus 70 °C. If you need lower temperature testing, please contact the editor for customization!

Humidity Test:

The programmable constant temperature and humidity test chamber can conduct humidity tests. It can simulate humid climates, with the standard humidity range between 20% and 98% RH.

Constant Temperature and Humidity Test:

This chamber can carry out constant temperature and humidity tests, including high-temperature/high-humidity and low-temperature/low-humidity scenarios. A common example is the Double 85 test, where the chamber is set to 85°C with 85% humidity conditions to assess the reliability of test samples.

Hot and Humid Test:

It can do hot and humid test (alternating hot and humid test, also known as the hot and humid test,) that is to simulate the harsh environmental climate of spring, summer, autumn and winter to test the product is resistant to complex and abnormal changes in the climate, if a long time in such an environment, the product needs to have sufficient resistance to alternating hot and humid capabilities.

Other Tests:

This testing machine can also carry out temperature and humidity cycle test, high and low temperature cross-border test, low temperature and low humidity test, high temperature and high humidity test, high and low temperature cycle test, wet freezing test, thermal cycle test, temperature cycle, and other different test conditions.

Issue Analysis:

- Compressor Water Ingestion Causes

When ice blockage occurs in the constant temperature and humidity test chamber, the technician suggests addressing the heating element’s susceptibility to blockage. This involves releasing fluorine, purging nitrogen-filled drying lines, and re-pumping fluorine. If ice blockages persist, it’s likely due to incomplete evacuation or excess fluorine-contaminated water. Notably, many of these failures stem from the compressor drawing in water. - Chamber Sealing Problem:

Inadequate sealing of the constant temperature and humidity test chamber liner allows a significant amount of airborne water to penetrate the insulation layer. Leakage occurs during refrigerant leakage events. Prolonged operation without compressor shutdown results in negative pressure on the equipment’s low-pressure side, causing substantial water suction into the compressor through leakage points and leading to recurrent ice blockages.

Solution:

Method 1: Carefully apply heat to the compressor and evaporator using an electric stove or light bulb. This facilitates the evaporation of water within the compressor and the system. Subsequently, use a vacuum pump to remove the water along with the air.

Method 2: Weld opens the high-pressure pipe and filters the drier. Allow the compressor to idle 2 to 3 times, utilizing the temperature rise of the compressor to evaporate and discharge water. Each idle session should be around four hours to prevent compressor damage.

It helps assess product quality and reliability and identifies manufacturing defects and weaknesses.

It shows the product decay and degradation process and helps predict its potential lifetime.

Evaluate the response of materials (including biological, industrial, and electronic) to selected conditions.

Constant temperature and humidity test chamber

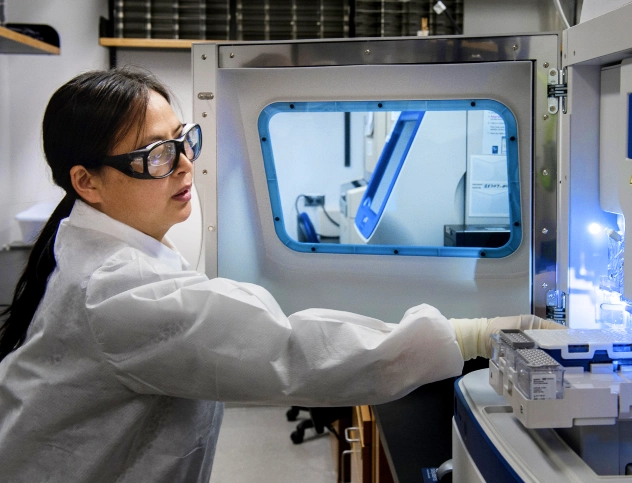

This chamber is mainly used to test materials in different environmental conditions. It tests materials’ ability to withstand heat, cold, dryness and moisture. The chamber has a precise control system for temperature and humidity. It is used for industrial research, biotechnology testing, and creating simulated environmental conditions. This chamber is widely used in drug and food processing, as well as for aseptic tests, stability checks, and testing the performance, life, and quality of industrial products, raw materials, and plastic, metal, food, medical, aerospace, instrumentation, and vehicle products.

Drug stability test chamber

Pharmaceutical companies use it for testing drugs and new drugs. It includes accelerated tests, high-temperature tests, and bright light exposure tests. These tests assist pharmaceutical companies in selecting programs for testing drug stability. It measures the long-term temperature, humidity, and light conditions needed to evaluate drug failure.

Constant temperature and humidity test chamber humidity does not come down may have a variety of reasons. The following are some common reasons and solutions:

Faulty humidity sensor.

The humidity sensor may be damaged or malfunctioning, resulting in the inability to correctly measure humidity; it is recommended to replace the humidity sensor.

Poor sealing of the test chamber.

If the sealing of the test chamber is not good enough, outside humidity will enter the inside of the test chamber, resulting in humidity cannot be reduced, it is recommended to check the sealing of the test chamber and repair or replace the seals.

External environment humidity.

If the region itself has large humidity, it is easy to reach the saturation temperature in the constant temperature and humidity box, resulting in humidity can not be reduced; it is recommended that the use of saline cups and other humidity adjustment devices to help constant temperature and humidity box to achieve the required humidity.

Refrigeration system problems.

Refrigeration system may have problems, can not cool the air into cold air, humidity can not be reduced, it is recommended to check the refrigeration system work, repair or replacement of faulty parts.

Water tank leakage.

Often use constant temperature and humidity testing machine process, the water tank may leak, which will lead to a drop in humidity, it is recommended to check the water level of the constant temperature and humidity testing machine water tank, add enough water at any time.

First, Temperature Control

Constant temperature and humidity machine temperature control is to ensure the normal operation of the equipment is one of the important factors. In the debugging temperature control, need to pay attention to the following points:

- Set a reasonable temperature value. According to the actual demand, set a reasonable temperature value, in general should not exceed the maximum temperature value of the equipment.

- Check the sensor position. The location of the sensor placement should be close to the inside of the equipment to avoid external temperature interference.

- Adjust the scale factor. According to the actual measurement, adjust the scale factor to ensure control accuracy.

Second, Humidity Control

The humidity control of constant temperature and humidity machine is also very important. When debugging humidity control, you need to pay attention to the following points:

- Set a reasonable humidity value. According to the actual demand, set a reasonable humidity value, generally should not exceed the maximum humidity value of the equipment.

- Check the sensor location. The location of the sensor placement should be close to the inside of the equipment to avoid external humidity interference.

- Adjust the scale factor. According to the actual measurement, adjust the scale factor to ensure control accuracy.

- The machine installation and set up to pay attention to not let dust, wire, iron filings or other things into, otherwise it will occur misoperation or failure.

- The wiring must be correct, must be grounded. Not grounded may cause electric shock, false action accidents, abnormal display or large error in measurement.

- Check the screws and fixing bracket regularly, please don’t use it in loose condition.

- Do not use the machine if you find it damaged or deformed when opening the box.

- Ventilation holes of the machine body need to be kept clear to avoid malfunction, abnormal action, reduced life span and fire.

- Don’t disassemble, process, modify or repair the machine without authorisation, otherwise there will be a danger of abnormal action, electric shock or fire.

- This product is non-explosion-proof, please do not use it in the bad environment of combustible or explosive gas.

- In order to avoid machine failure, please provide power supply within the rated voltage range.

- In order to prevent electric shock or produce false operation and failure, please do not turn on the power before the end of installation and wiring.

① Compressor damage or not open, replace the compressor and check the control compressor line and control components are damaged

② Refrigerant leakage, with nitrogen leak detection method to find the leak, welding, vacuum, add refrigerant, re-commissioning

③ Solenoid valve abnormal action, replace the solenoid valve, check the solenoid valve control line

④Capillary tube clogging, replace the capillary tube, replace the filter drier, with nitrogen blowing clean condensing system impurities, add refrigerant debugging

⑤ Condenser icing, heating and drying the water in the box, and then cool down

⑥ Bad heat dissipation, the use of equipment at the site to install the appropriate power of the air conditioning cooling or open the doors and windows so that the air can circulate

- First, its direct evaporative cooler surface frost or ice conditions, thus increasing the heat transfer thermal resistance to affect the heat transfer effect, thus making the evaporation temperature gradually reduced so that the evaporation pressure is reduced.

- Second, in the constant temperature and humidity test chamber of the refrigeration system is a dirty blockage, and especially for the Freon system, and because of the dirt will make the filter drier and the finer piping clogged, so the system will exist in the water to affect the expansion valve to produce the phenomenon of ice blockage.

- Third, the refrigerant in the refrigeration system is insufficient.

- Fourth, the water-cooled system of cooling water is too much so that the amount of refrigerant is too small, and must be adjusted to the flow of cooling water and refrigerant.

- Fifth, the load adjustment switch opening degree is not enough, the cooling capacity of the refrigeration equipment and is greater than the required heat load.

- Constant temperature and humidity chamber sealing degree

If the box sealing strip is not customised gap, or thermostat box door leakage, will greatly affect the uniformity of the temperature of the test box, so the sealing strip for the test box is quite strict requirements, must have the characteristics of high temperature and low temperature.

The solution to the uneven temperature: pay attention to the sealing of the box, to prevent local air leakage, should choose the excellent performance of the thermal insulation materials, quality assurance of the thermal insulation material is the key point of the accurate uniformity of the constant temperature and humidity box test box insulation materials if not handled well, will directly lead to the box uniformity deviation is too large. - Constant temperature and humidity box structure

Constant temperature and humidity chamber in the internal structure, space planning is sometimes difficult to achieve uniform symmetrical structure, affecting the indoor heat convection, will lead to the internal temperature uniformity error.

To solve the problem of temperature unevenness: pay attention to the volume, weight and placement of the sample, the relevant standards provide for the total volume of the sample is less than 1/5 of the internal, to leave enough ventilation space, in the wind surface of the sample area should be less than 1/3 of the wind cross-section, can not be placed on the test products around the air ducts, which will seriously affect the wind cycle, the test samples should be placed steadily to ensure that the placement of the smooth.

Attention should be paid to the air convection inside the box, when doing the test, if the test object is too large, or placed in an inappropriate location and way, will also produce a large temperature uniformity deviation. - Constant temperature and humidity chamber circulation system

Constant temperature and humidity chamber through the wind circulation system to improve the temperature uniformity inside the box, air conditioning duct at the rear of the box, through the heating tube to heat the air after the long axis motor drives stainless steel multi-wing centrifugal wind wheel, stirred evenly, and then through the louvre outlet to achieve temperature uniformity.

The solution to the uneven temperature: reduce the temperature difference between the air supply, reduce the temperature difference between the air supply can reduce the impact of the airflow on the temperature field in the working room, can be more effective to protect the temperature difference. And increase the amount of air supply can both reduce the temperature difference between the air supply and ensure that the reduction of indoor air flow. - Constant temperature and humidity box internal heat transfer

Due to the test box wall has a threading hole, detection holes, test holes and other local heat transfer, so that the box temperature is not uniform, so that the radiation convection heat transfer is not uniform, affecting the temperature uniformity.

The solution to the uneven temperature: improve the control accuracy of the constant temperature and humidity environment box, reduce temperature fluctuations, for the temperature rise process of the test box, the heating power PID continuous adjustment can reduce temperature fluctuations; for the cooling process of the test box, in order to reduce the temperature fluctuations, usually using a thermal balance method of temperature control. For the cooling process of the test chamber, in order to reduce temperature fluctuations, the heat balance method of temperature control is usually used.

There may be several reasons why the constant temperature and humidity test chamber does not cool:

- The temperature setting is too high: if the temperature set in the test chamber is too high, resulting in the temperature inside the test chamber being higher than the target temperature, the refrigeration system will not start.

- Low ambient temperature: if the ambient temperature around the test box is too low, the refrigeration system will not start. This may be because the test chamber is placed in too cold an environment, or the test chamber refrigeration system temperature sensor failure.

- Refrigeration system failure: the test chamber refrigeration system may be faulty, such as refrigerant leakage, refrigeration compressor failure, etc., resulting in the normal cooling.

- Low humidity setting: if the humidity setting of the test chamber is too low, the relative humidity inside the test chamber may be lower than the target humidity, and the refrigeration system will not start.

In the case of the test box does not cool, you need to first rule out the above possibilities, and then take the appropriate maintenance measures.

1. Testing the performance of products under various temperature and humidity conditions

Constant temperature and humidity test chamber can simulate a variety of temperature and humidity environments, such as high temperature and high humidity, low temperature and low humidity, high temperature and low humidity, etc., for testing the performance of products in these environments. Through the test, the performance, reliability and stability of the product in various environmental conditions can be assessed, so as to provide a basis for product design and improvement.

2. Testing the weather resistance and adaptability of materials

Constant temperature and humidity test chamber can simulate the temperature and humidity changes in the natural environment, used to test the weather resistance and adaptability of materials. Through the test, it can assess the performance of materials in different environmental conditions, such as whether deformation, discolouration, cracking and other phenomena, so as to provide a basis for the selection and application of materials.

3. Testing product packaging and protection measures

Constant temperature and humidity test chamber can simulate a variety of environmental conditions, such as high temperature and high humidity, low temperature and low humidity, etc., for testing product packaging and protective measures. Through the test, it can assess whether the packaging materials, sealing performance and protective measures of the product can effectively protect the product from the influence of environmental factors, thus improving the reliability and service life of the product.

4. Testing the biological safety of products and biomedical materials

Constant temperature and humidity test chamber can simulate the biological safety and biomedical material performance under various temperature and humidity conditions. Through the test, it can assess the biological safety of products and biomedical material performance, such as whether it will cause infection, spread disease, etc., so as to provide a basis for product safety and medical applications.

5.Testing the reliability and stability of electronic products

Constant temperature and humidity test chamber can simulate the performance of electronic products under various temperature and humidity conditions. Through the test, the reliability and stability of electronic products can be assessed, such as whether the phenomena of circuit short-circuit, disconnection, battery leakage, etc., thus providing the basis for the quality and reliability of electronic products.

6.Testing the performance and reliability of medical equipment

Constant temperature and humidity test chamber can simulate the performance of medical devices under various temperature and humidity conditions. Through testing, the performance and reliability of medical devices can be assessed, such as whether it can accurately measure the patient’s physiological parameters, whether it can effectively transfer heat, and so on, so as to provide a basis for the quality and safety of medical devices.

7. Testing the storage and transport conditions of food

Constant temperature and humidity test chambers can simulate food storage and transport environments under various temperature and humidity conditions. Through the test, the quality and safety of food in these environments can be assessed, such as whether deterioration, decay and other phenomena will occur, so as to provide a basis for the storage and transport of food.

8. Testing the stability and adaptability of cosmetics

Constant temperature and humidity test chamber can simulate the performance of cosmetics under various temperature and humidity conditions. Through the test, the stability and adaptability of cosmetics can be assessed, such as whether separation, precipitation and other phenomena will occur, thus providing a basis for the quality and safety of cosmetics.

9. Testing the performance and reliability of new energy products

Constant temperature and humidity test chamber can simulate the performance of new energy products under various temperature and humidity conditions. Through testing, the performance and reliability of new energy products can be assessed, such as the photoelectric conversion efficiency of solar panels, wind power generation equipment, operational stability, etc., so as to provide a basis for the development and application of new energy products.

10. Provide experimental data and support for scientific research

Constant temperature and humidity test chamber can simulate a variety of temperature and humidity conditions of the environment, to provide experimental data and support for scientific research. For example, in materials science, biology, physics and other fields of research, need to simulate different temperature and humidity conditions of the experimental environment, in order to explore the nature of various materials and application prospects. Through the test of constant temperature and humidity test chamber, it can provide accurate and reliable experimental data and support for scientific research.

Constant temperature and humidity test chamber maintenance need to pay attention to the following points:

- Regular cleaning: The internal and external cleaning of the test box should be carried out frequently, you can use a clean cloth or soft brush cleaning, do not use chemical solvents.

- Maintenance of the constant temperature and humidity system: The parts of the constant temperature and humidity system need to be checked and replaced regularly to ensure the normal operation of the system.

- Maintaining the heating system: The heaters and sensors of the heating system need to be inspected and cleaned regularly to ensure that they work properly.

- Maintain the refrigeration system: The compressor and condenser of the refrigeration system need to be inspected and cleaned regularly to ensure its proper functioning.

- Ensure the safety of the power supply: The power supply of the test chamber needs to be checked and maintained regularly to ensure its safety and reliability.

- Regular calibration: The temperature and humidity sensors inside the test chamber need to be calibrated regularly to ensure the accuracy of the test results.

1.Product Performance Verification: Evaluate and verify the performance, reliability and durability of products or materials under specific temperature and humidity conditions by simulating these conditions.

2. Reliability testing: Ensure that the product can work properly even in extreme environments, so as to improve the reliability of the product.

3. Quality control: Discover potential problems and defects, repair them in time and reduce product failure rate.

4.Material Evaluation: Evaluate the performance differences of materials under different environmental conditions, optimise product design, and improve product performance and competitiveness.

5. Simulate the actual use of the environment: simulate the temperature and humidity of the product work, storage environment, to understand whether the product performance in all aspects of the requirements.

6. Compliance with industry standards: Ensure that the products comply with the relevant standards and regulations to increase the competitiveness of the products in the market.

7. Accelerated life test: By improving the environmental conditions, such as temperature and humidity, the life and reliability of the product can be assessed in a shorter period of time.

In short, constant temperature and humidity test is an important environmental reliability test, which provides an important means to assess and verify the performance, reliability and stability of products or materials, and helps enterprises to assess the performance of products in different environmental conditions, predict product life and reliability, and optimise product design.

1、Temperature range

Rapid temperature change test chamber, temperature range: -20 ~ +150 ° C, -40 ° C ~ +150 ° C, -70 ° C ~ +150 ° C; rapid temperature change range: -60 ° C ~ +85 ° C, +85 ° C ~ -60 ° C (that is, only in this range is able to do the rapid change of temperature, the other temperatures can be done, but can not reach the rapid change of the temperature rate)

Constant temperature and humidity test chamber, temperature range: -20 ℃ ~ +150 ℃, -40 ℃ ~ +150 ℃, -70 ℃ ~ +150 ℃

2、Rate of temperature rise/fall

Rapid temperature change test chamber has relatively fast requirements for the rate of temperature rise and fall, while the constant temperature and humidity test chamber temperature rise and fall rate is relatively much smaller.

Rapid temperature change test chamber temperature rise and fall rate is divided into two kinds, one for the linear temperature rise and fall 3 ℃ -15 ℃ / min, linear distribution is uniform, there are rules; the other kind of non-linear temperature rise and fall 3 ℃ -15 ℃ / min, non-linear distribution is not uniform, irregular to take the average value. (There are 3 ℃ / min, 5 ℃ / min, 8 ℃ / min, 10 ℃ / min, 15 ℃ / min, 3 ℃ ~ 15 ℃ / min between the user can choose according to their own requirements for testing conditions)

Constant temperature and humidity test chamber has a limited rate of temperature rise and fall, temperature rise: 3 ℃ / min ( -20 ℃ ~ +100 ℃ about 35min ), cooling: 1 ℃ / min ( +20 ℃ ~ -20 ℃ about 45min )

3、Humidity range

Rapid temperature change test chamber humidity range is optional, that is to say, you can do humidity, you can not do humidity, according to the customer’s requirements to customise;;

Constant temperature and humidity test chamber humidity range is: 20% ~ 98% R.H. / 30% ~ 98% R.H. (10% ~ 98% R.H. / 5% ~ 98% R.H. for the special selection of conditions), that is to say, it must have humidity.

4、Cooling system

Rapid temperature change test chamber using water-cooled cooling, because it is too fast temperature change;

Constant temperature and humidity test chamber test box using air-cooled or water-cooled, generally small boxes using air-cooled, large boxes using water-cooled.

Vertical is with a compressor, and desktop is not with a compressor, because it does not come with a compressor, so it does not have the function of refrigeration this effect.

The vertical temperature range will be greater than the desktop temperature range, can be done below the low temperature, while the desktop can only be done above room temperature, generally more common desktop constant temperature and humidity box is desktop, the temperature range is different, the range of humidity will vary greatly, vertical humidity range will be wider than the desktop range, but the vertical must be slightly higher than the desktop cost.

1. Different uses

High and low temperature test chamber is mainly used to test the degree of product tolerance in high temperature, low temperature and other extreme environments, to verify the product’s heat resistance, cold resistance and moisture resistance. Constant temperature and humidity chamber is mainly used to simulate different climatic conditions in a stable environment, and test the performance of products in a long-term harsh environment.

2. Different temperature control methods

High and low temperature test chamber generally use compression refrigeration to achieve high and low temperature control, and usually equipped with a fan circulation system to uniformly transfer the temperature. Constant temperature and humidity chamber adopts advanced PID control technology, through the control of water tank heating or refrigeration to achieve temperature control, and is equipped with humidity sensors to control humidity.

3. Different ways of use

The use of high and low temperature test chamber scene is usually placed in the machine to achieve the set temperature, observe and test its performance in this temperature conditions. Constant temperature and humidity chambers need to maintain a constant temperature and humidity for a long time to simulate the real use of the scene, usually need to carry out several days of testing to get reliable data.

First of all, from the appearance, desktop constant temperature and humidity test chamber is usually a rectangular or square box, the whole presents a lower height, can be placed in the laboratory on the table. Vertical constant temperature and humidity test chamber presents a higher height, similar to a column, need to be placed on the ground.

Secondly, from the use of the way to see, desktop constant temperature and humidity test chamber is usually through the top of the open cover for the placement of samples and take out, the operation is more convenient. While the vertical constant temperature and humidity test chamber is usually through the front door for the placement and removal of samples, need to bend or squat to operate.

In addition, from the point of view of space utilisation, desktop constant temperature and humidity test chamber usually takes up less space, suitable for laboratory space is limited in the case of use. While the vertical constant temperature and humidity test chamber occupies a larger space, suitable for laboratory space is more spacious in the case of use.

Finally, from the price point of view, desktop constant temperature and humidity test chamber is usually cheaper, suitable for users with limited budget. While the vertical constant temperature and humidity test chamber is more expensive, suitable for users with a more abundant budget to choose.

1. A kind of energy saving and consumption reduction environment simulation equipment, the compressor selects R404A medium and low temperature compressor;

2. An energy-saving environment simulation equipment, the principle is that the electronic expansion valve automatically adjusts the flow size of the refrigeration medium, and then flows through the evaporator to achieve real-time adjustment of the size of the refrigeration capacity, reduce the heating power output, so as to achieve energy-saving and consumption reduction;

3. A kind of energy saving and consumption reduction environment simulation equipment, the principle is that, the other end of the capillary tube is connected to the compressor low pressure circuit, to prevent the compressor low pressure end of the high temperature phenomenon, and damage to the compressor;

4. An energy-saving environmental simulation equipment, the principle is that the filter drier effectively adsorbs water in the circuit as well as filtering solid impurities, to prevent blockage of the pipeline. Then flow through the solenoid valve

5. A kind of energy-saving environment simulation equipment, the principle is that, when the absorption temperature is too low, open the solenoid valve flow through the capillary high temperature and high pressure gaseous media, improve the evaporator inlet temperature, to ensure that the system operates normally;

6. A kind of energy saving and consumption reduction environment simulation equipment, the principle is that, the drying filter and the solenoid valve is connected to a high pressure switch at any position between. When the system pressure is too high, the function of protecting the compressor.

Firstly, the energy-saving constant temperature and humidity tester adopts advanced energy-saving technology, which can save energy while maintaining stable temperature and humidity control. It adopts a highly efficient equipment cooling system, which effectively radiates heat out and avoids the waste of energy. Compared with traditional test chambers, energy-saving test chambers can reduce energy consumption and lower operating costs, thus saving users a lot of electricity expenses.

Secondly, the energy-saving constant temperature and humidity test chamber also has an intelligent control function, which can realise precise temperature and humidity control and has automatic adjustment function. It is equipped with advanced temperature and humidity sensors and control system, which can monitor the temperature and humidity changes inside the test chamber in real time and automatically adjust according to the set parameters. This intelligent control function not only improves the stability and accuracy of the test chamber, but also saves human resources and improves work efficiency.

In addition, the energy-saving constant temperature and humidity test chamber also has good sealing performance and heat insulation performance. It adopts high-quality sealing materials and heat insulation materials, which can prevent heat leakage and temperature and humidity interference, and ensure the stability of temperature and humidity inside the test chamber. Excellent sealing performance and thermal insulation not only improves the efficiency of the test chamber, but also improves the accuracy and reliability of product testing.

The energy-saving constant temperature and humidity test chamber also has a long service life and low failure rate. It adopts corrosion-resistant materials and advanced manufacturing process, which has good durability and stability. Under normal use and maintenance conditions, the energy-saving test chamber can run stably for a long time and is not easy to fail, thus greatly reducing the cost of repair and replacement equipment.

In addition, the energy-saving constant temperature and humidity test chamber also has flexible operability and diversified functions. It is equipped with user-friendly operation interface and multiple test modes, which can meet the needs of different users. Users can flexibly set the temperature and humidity parameters and test time according to the specific test requirements to achieve a variety of test objectives. This flexible operability and diversified functions make the energy-saving test chamber widely used in the R&D and production process of various industries.

Environmentally friendly: modern constant temperature and humidity test chambers usually use environmentally friendly refrigerants, such as R-134a, R-404A, etc. These refrigerants do not destroy the ozone layer, so they have a higher degree of environmental protection.

High-efficiency refrigeration system: constant temperature and humidity test chamber usually adopts new high-efficiency refrigeration technology, such as frequency conversion compressor, heat pump technology, etc. These technologies can improve the efficiency of the refrigeration system and reduce energy consumption.

Heat pump circulation system: the heat pump circulation system can recover the thermal energy generated inside the test chamber, and convert it into heating energy, further reducing energy waste.

High-efficiency heating system: constant temperature and humidity test chamber using the heating system usually infrared or thermal oil and other high-efficiency heating technology, these technologies can reduce the heating system energy consumption.

Timing function: constant temperature and humidity test chamber usually has a timing function, can be set according to the time to start and stop, reduce unnecessary energy consumption.

Temperature control technology: modern constant temperature and humidity test chamber usually adopts intelligent temperature control technology, which can accurately control the internal temperature and humidity of the test chamber to avoid energy waste.

Equipment automation: modern constant temperature and humidity test chamber usually adopts automation control system, which can realise the automatic control and monitoring of the equipment and further reduce the energy consumption.