In coatings and finishes, the durability of paints and varnishes plays a crucial role. This is significant for maintaining the aesthetic appeal and protection of surfaces. But exposure to various environmental factors can speed up the ageing process. These factors include UV radiation, leading to premature coatings degradation. It is vital to ensure the performance and reliability of paints and varnishes. For this, UV ageing testing chambers have emerged as an indispensable tool.

What Are UV Aging Testing Chambers?

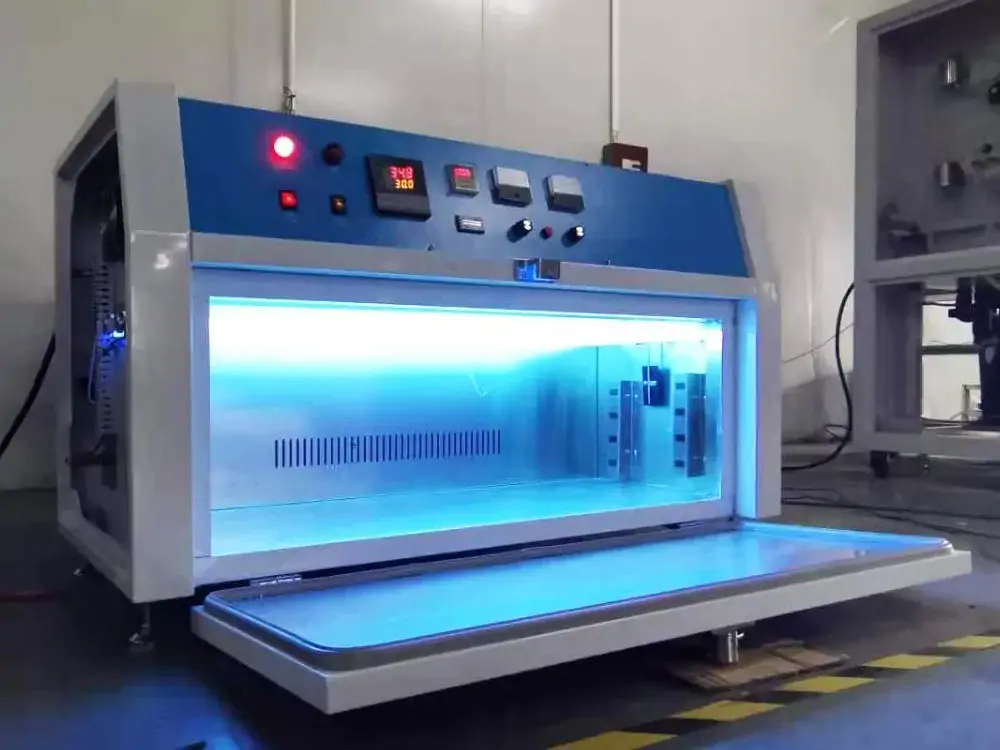

UV-ageing testing chambers are also known as weathering test chambers. They simulate various environmental conditions. These include sunlight, humidity, and temperature. This chamber helps to assess the resistance of materials to ageing processes. The UV chambers replicate the effects of natural weathering. So it helps manufacturers test the durability of paints, varnishes, and plastics. This process usually works over time and gives results.

Significance of UV Aging Testing Chambers

It is important to keep in mind the importance of these UV-ageing testing chambers. The exposure of paints and varnishes to UV radiation activates the degradation process. This results in chalking, cracking, loss of adhesion, and color fading. This is helpful for manufacturers to predict behavior in real-world conditions. The results show that when they undergo exposure to controlled UV in testing chambers. This proactive approach is beneficial for detecting the issues earlier. This helps to develop formulations that withstand prolonged exposure to sunlight. This ensures the longevity and quality of finished products.

UV Aging Test Methods for Paints and Varnishes

UV testing plays a vital role in helping to test resilience and performance. This is helpful during the manufacturing of paints and varnishes for durability. The long-term UV exposure helps in the evaluation. We will explore the various UV ageing test methods that assess the resistance of coatings. This testing is helpful when things are under different environmental stressors.

Accelerated Weathering Test

This test is a cornerstone that evaluates durability and resilience. This test works for samples like paints and varnishes. It is a vital tool for manufacturers to simulate the effects of prolonged exposure. Exposure to various environmental stressors is beneficial for the manufacturing process. The exposure is to UV radiation in a controlled laboratory setting.

In this method, samples undergo exposure to UV radiation in a controlled environment. This is usually done in a weathering chamber. The duration and intensity of UV exposure are easy to adjust. This helps to simulate various climatic conditions. Thus, this helps manufacturers speed up the ageing process. Also, it assesses the long-term durability of coatings in a small fraction of time.

UV test methods are paramount for painting and varnishing. This testing helps provide valuable insights into the performance of coatings. This process is helpful for the long term. Also, it is easy to identify weaknesses and optimise formulations to increase durability. Furthermore, it is a quality assurance tool. This helps manufacturers verify compliance with industry standards and regulatory requirements. It is important to test different coatings and see their resistance. The resistance to UV and stressors is helpful for consumers, contractors, and architects.

The test is a crucial method for assessing the resilience of paints and varnishes. This method shows results from intense UV radiation. This test utilizes xenon arc lamps to simulate sunlight. It plays a role in predicting the performance of coatings under outdoor conditions.

In this method, samples are exposed to intense UV radiation. These xenon arc lamps generate these UV radiations. These lamps emit a spectrum of light that resembles natural sunlight. It allows testers to replicate outdoor conditions. Also, it evaluates the weathering ability of coatings. This includes resistance to colour fading, chalking, cracking, and loss of gloss.

It provides manufacturers with invaluable insights into the long-term durability of coatings. This test is crucial in the development and evaluation of paints and varnishes. This makes accurate predictions of how coatings will work under outdoor conditions.

Fluorescent UV Test

The fluorescent UV test, also known as the UVB test, It focuses on assessing the resistance of coatings to UVB radiation. This causes surface degradation and discoloration.

In this test, samples are exposed to fluorescent UV lamps. These lamps emit UVB radiation at specific wavelengths. It helps to test the performance and durability under certain conditions. This includes conditions that mimic prolonged exposure to sunlight.

This approach detects weaknesses in formulations. Then, it becomes easy to make the necessary adjustments. This test checks changes in colour, adhesion, gloss, and mechanical properties.

QUV Test

The OUV test is the QUV Accelerated Weathering Test. It is a UV ageing test method. This includes UV radiation, humidity, and temperature control to simulate environmental conditions.

In this test, samples undergo exposure to alternating cycles of UV radiation. Besides UV, it undergoes moisture cycles as well. Also, after these, they include periods of darkness and humidity. The test replicates the effects of sunlight, dew, and rain. It provides insights into the durability of coatings in outdoor environments.

The test incorporates cycles of moisture and temperature fluctuations. This also includes thermal cycling in outdoor environments. This test shows how coatings will fare over time.

Salt Spray Test

The salt spray test is not a UV ageing test. It is different from UV testing. But, this test helps to test the corrosion resistance of coatings.

In this, samples undergo exposure to a fog, or saline mist. This simulates the corrosive effects of saltwater exposure. This helps to assess the extent of corrosion. Also, it helps manufacturers track the performance of coatings. This test works great in marine environments that are prone to salt contamination.

It helps test resistance to salt spray corrosion. The challenges are due to marine environments, coastal regions, and industrial settings. Because salt contamination is prevalent.

Conclusion

Throughout this guide, we have gone through various UV test methods. These test methods help to assess the durability of paints and varnishes. This is helpful for testing different environmental stressors. These testing methods predict how coatings will perform under real-world conditions. The conditions include exposure to moisture, temperature variations, and sunlight. Also, it includes some corrosive elements, such as salt water. Thus, these tests prove to be helpful to manufacturers in developing coatings. The coatings should withstand outdoor exposure and ensure long-term protection.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]