High and low temperature testing finds out how well products adapt to extreme temperatures in storage, transport, and use. The severity of the test depends on the high or low temperature and the duration of exposure. All products are stored, preserved, or work in certain temperature environments. Some environments have constantly changing temperatures, sometimes high and sometimes low.

High and low temperature testing applications

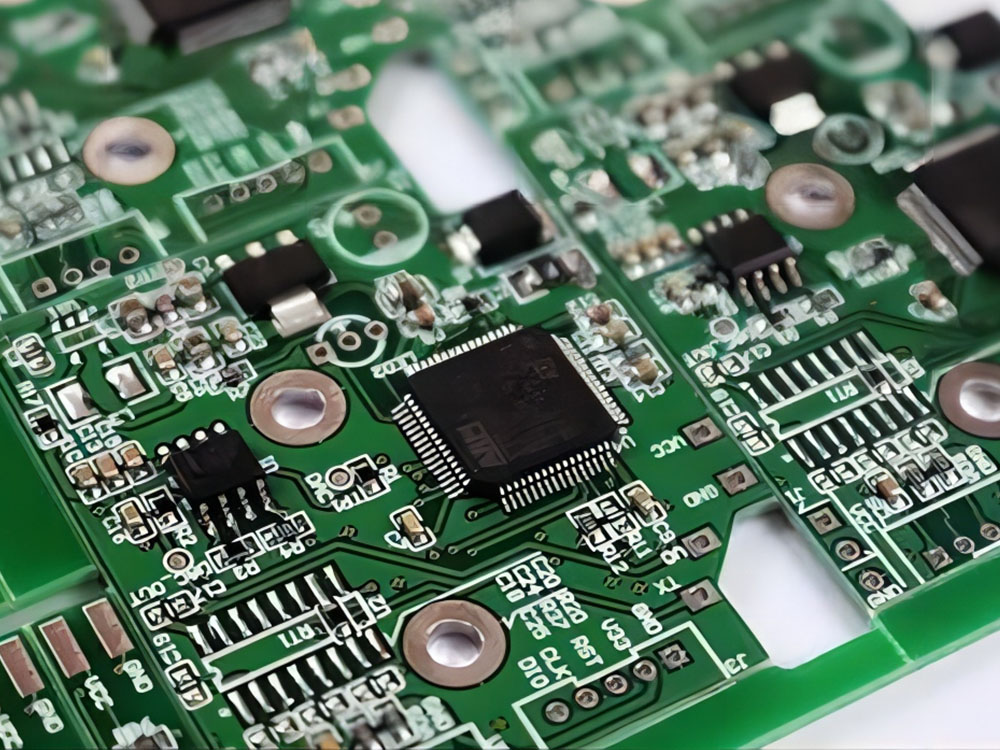

Electronics, components, circuit boards, communications, LED, LCD, instruments, capacitors, vehicles, medicine, plastic, metal, chemical, building materials and other industry products. Test the performance indicators in extreme heat, cold, or humidity. The stringency of the test depends on the high and low temperature and the duration of the test. High and low temperatures may cause the product to overheat. This can affect its safety and reliability, or even damage it.

The different expansion coefficients of materials cause bonding and migration between them.

Changes in material properties

Decrease in electrical properties of components

Reduce the elasticity or strength of elastic parts. This shortens product life.

Speed up the aging of polymers and insulators. This will shorten product life.

Reduce the elasticity of rubber and other flexible materials and cause rupture.

Increase the brittleness of metals and plastics, resulting in rupture or cracking

Low temperatures can make materials brittle. Plastics and steel can crack. Rubber becomes harder and less elastic.

High and low temperature test standards

GB_T 2423.2-2008. Environmental test for electrical and electronic products. Part 2: Test methods. Test B: High temperature.

GBT 2423.1-2008 Environmental test for electrical and electronic products. Part 2: Test method. Test A: Low temperature.

IEC 60068-2-2 Basic environmental test procedure Part 2-2: Test Test B: Dry heat

IEC 60068-2-1: 2007 Environmental testing of electrical and electronic products: low temperature

Test equipment

The AtmoExplorer Constant Temperature and Humidity Chamber tests materials in various environments. It checks their resistance to heat, cold, dryness, and humidity. It is suitable for testing products in electronics, appliances, phones, and more. This includes vehicles, plastics, metals, food, chemicals, and building materials. It can also test medical and aerospace products. The AtmoExplorer Tester can test high and low temperature and humidity. It also tests for constant temperature and humidity. It can accurately simulate these conditions. This helps researchers see how products perform in extreme environments. The test chamber can simulate these conditions. It will help researchers understand how products perform in these environments.

In constant temperature and humidity tests, we apply humidity to the hot section. When analyzing the failure from humidity, consider the effects of high temperatures followed by low ones. Moisture intrusion into the material causes decay, mold, and deformation. High temperature and humidity can occur at the same time. The insulating material will absorb moisture. This may cause swelling, blistering, and deformation. It can also increase friction in moving parts or even cause them to stick. Additionally, a change in temperature can cause frost due to the humidity. Thus causing electrical short circuit. Humidity can degrade organic materials and their electrical properties. At high temperatures, it can also contaminate the contacts, leading to poor connections.

The main failure modes induced by humidity are.

Electrical short circuits

Sticking of active components

Corrosion of circuit boards

Surface damage

Reduced performance of insulation materials, etc.

High and low temperature test classification

①High temperature working test

In high temperatures, the test equipment must work normally. During the high-temperature test, it must not fail.

② low-temperature working test

The subject equipment works normally in low temperatures. During low-temp tests, it should not fail.

③ high-temperature storage test

In high heat, the subject equipment was tested while off. Its performance was normal.

④ low-temperature storage test

In low temperatures, the subject equipment is off. A low-temp test shows it works fine.

High and low temperature test procedure

The high and low temperature test uses a programmable chamber. It can both heat and cool. Before the test, check the test sample. Its appearance, function, and performance should be normal. Also, take pictures.

Put the sample in the high and low temperature box. Set the box’s high and low temperature values, holding times, and temp change time. Also, set the number of cycles. For example, maintain a high temperature of 70 °C for 2 hours. Then, for 30 minutes, lower it to -20 °C. Maintain that for 2 hours. Finally, for 30 minutes, raise it back to 70 °C. Repeat this cycle 20 times.

After the test, check the sample’s appearance and performance. If the sample shows no change, it passes the tests. If there is a change in the standard range, it does not meet them.

Comparison of the application of high and low temperature test chamber test methods

Heat dissipation test samples with and without forced air test

Most methods for high and low temperature test chambers use wind circulation. A fan generates a wind flow to create a uniform temperature.

A test without forced air circulation simulates free air conditions. It is better for thermal tests of samples.

A forced air circulation test is when it is hard to ensure test conditions without forced air. When that happens, both methods can be used with forced air.

Non-heat dissipation test samples and heat dissipation test samples

Conditions test sample temperature stabilisation during the test, measured in free air conditions. If the hottest point on the test sample is over 5 ℃ above the air temperature, it is a heat-dissipating sample. Otherwise, it is a non-heat-dissipating sample. All storage tests must not energise or load the test samples. They are non-heat-dissipating samples.

Non-heat dissipation test samples

High and low temperature test chamber temperature gradient test. The former is a rapid change in temperature test chamber. The latter is a high and low temperature test chamber.

① temperature gradual change test: the first test sample with room temperature into the same room temperature test chamber, and then open the cold source will be gradually cooled to the specified test temperature, if the test sample is too large or too heavy, or due to the complexity of the functional test wiring, in the sudden change of the test can not be done in the low-temperature box and does not produce a frost situation, it should also be used when the test;

② temperature mutation test: First, adjust the test box to the specified temperature. Then, put in a room temperature test sample. This method applies to samples that are known to not produce a temperature mutation.

High and low temperature test result requirements

The surface of the product should be free from damage, deformation and other defects. If the surface is coated, it should show no flaking, blistering, or discoloration.

For plastic parts, the surface is free of cracks, blistering and deformation.

Rubber products are free from aging, bonding, softening and cracking.

There is no flowing phenomenon in the welding parts of the product parts.

The product must meet the technical conditions. Its performance data and structure must work as required. There must be no other defects that prevent normal operation.

Selection of high and low temperature test chamber test eight points

Select high and low temperature test chambers or other equipment. They must meet the test’s temperature requirements.

To keep a uniform temperature in the test area, choose between forced or unforced air circulation. Use the method based on the sample’s heat dissipation.

The heating or cooling system’s test chamber must not affect the sample. It must have no impact at high or low temperatures.

The test chamber must allow easy access to the sample rack. It will not change its mechanical properties due to temperature changes.

High and low temperature test chamber should have protection precautions. For example: an observation window, lighting, and alarms. Also, there is over-temperature protection, with a power phase failure.

According to customer requirements whether there is a remote monitoring function;

The test chamber for the cycle test must have:

Automatic counters, indicator lights, and recording equipment.

An automatic shutdown and other instrumentation devices.

A good record and display function.

The customer must choose the right equipment for their product tests. The high and low temperature test chamber can control the temperature and humidity. It has sensors at the control location. The sensors use upwind and downwind methods to measure the temperature.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]