UV weathering testing uses an ultraviolet light source to simulate sunlight. It irradiates a sample to assess how quickly it ages under UV light. This test method simulates prolonged UV exposure in real use. It assesses the material’s weathering performance and lifespan.

Scope of application

The UV weathering test applies to a wide range of materials and products, including but not limited to.

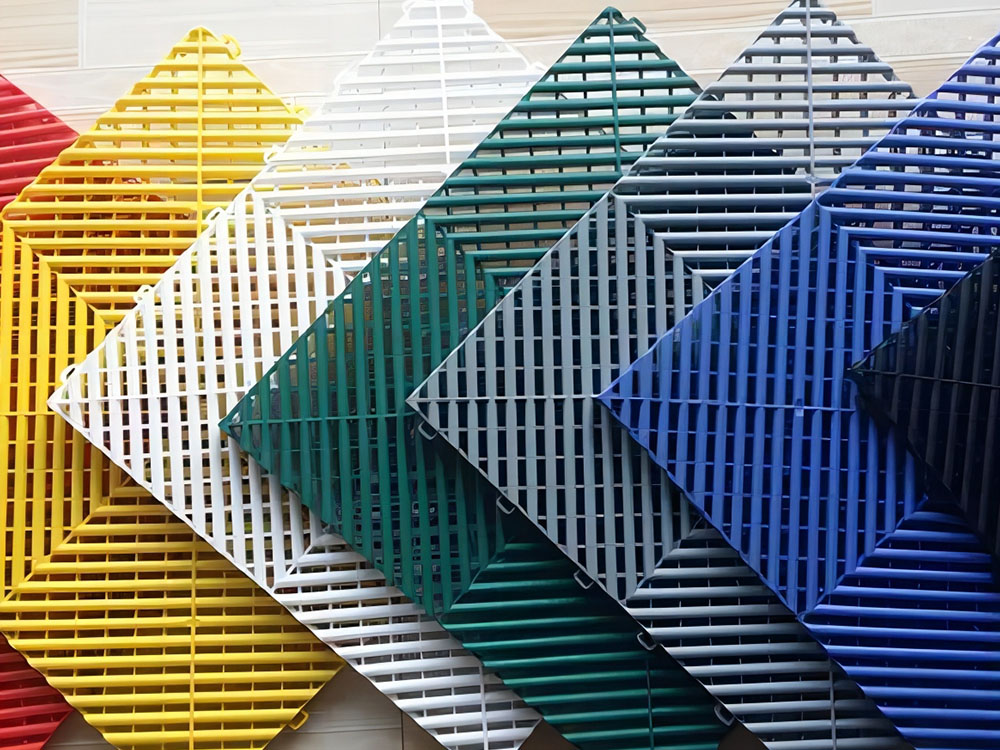

Non-metallic materials

Plastics, rubbers, and fabrics, for example. People use these materials outdoors. Long exposure to UV radiation will damage them.

Organic materials

Such as paints, lacquers, and dyes. UV rays may affect these materials whether they are used indoors or outdoors. This can change their properties.

Automotive materials

UV ageing tests check how durable auto parts are. They test shells, interiors, and tyres during use.

Packaging Materials

During storage and transport, UV light may expose packaging materials, such as paper and plastic film. This can affect their service life.

Building materials

After long use, strong UV rays expose roofing and windows. They are outdoor building materials. So, we need to conduct UV aging tests to evaluate their weathering performance.

Equipment housings for communications, electrical appliances, etc.

These devices are usually plastic or non-metallic. We require UV weathering tests to ensure their stability in harsh, outdoor environments.

Why UV Aging Test?

The main purpose of the UV ageing test is to simulate and speed up the ageing of a material or product. It does this by exposing it to UV radiation for a long time, as in a natural environment. This method can quickly show performance changes in materials due to UV exposure. These changes include discolouration, loss of light, and chalking. Also, there is cracking, crazing, fogging, blistering, brittleness, loss of strength, and oxidation. These changes may harm the product’s look, performance, and lifespan.

UV weathering testing lets manufacturers find design and material flaws. They can fix them before it’s too late. Such tests can help manufacturers predict their products’ service life. They are good for quality control and after-sales service. The UV aging test is vital for product development and quality control. It is also important for after-sales service.

Sunlight’s ultraviolet light is the main cause of material damage. Jinjian Labs uses UV lamps to simulate the short-wave UV part of sunlight. It produces very little visible or infrared energy. We can select different wavelengths of UV lamps for testing. Each lamp differs in total UV energy and wavelength.

Commonly Used Inspection Standards

Commonly used inspection standards:

GB/T 31881-2015 Automotive non-metallic parts and materials UV accelerated aging test method

GB/T 32088-2015. Xenon lamp accelerated aging test method for automotive non-metallic parts and materials.

GB/T 23987-2009 Artificial weathering exposure of colour paints and varnishes. Coatings exposed to fluorescent ultraviolet light and water.

GB/T 14522-2008 tests the climate aging of plastics, paints, and rubbers in industrial products. It is an artificial test. It uses fluorescent ultraviolet light.

Frequently Asked Questions and Answers for UV Aging Tests

1. What is the acceleration factor for UV testing?

Aging experts have been trying to find that magic number for decades, but there is no such magic number. No matter how you pose the question, the answer is always the same: ‘It depends on the reality!’ Here’s why:

Nature is not as reliable as laboratory equipment! In UV ageing tests, we use calibrated lamps and specific filters. We monitor irradiance very precisely. And we use pure water, controlled humidity, and temperature. We also use predefined cycles of light, darkness, and rainfall. On the other hand, outdoor exposure depends on the time and place: latitude, altitude, cloudiness, humidity, smoke, rainfall, temperature, direction, season, time of day …… All these factors greatly affect the ‘efficiency’ of outdoor exposure. So, they impact the acceleration factor.

Several studies and standards show an average acceleration factor of 9. This is for accelerated lab tests in harsh conditions like those in Florida and Arizona.

ASTM D6578 requires, for anti-graffiti coatings, 24 months of outdoor exposure (Florida or Arizona) or 2,000 hours of accelerated aging. In this case, they assume an acceleration factor of 8.8 (2 years (17,520 hours)/2000 hours).

In milder climates (such as Boston, Montreal, or Chicago), the acceleration factor increases. Studies show this type of climate speeds up polystyrene specimens by over 20 times.

2. What is the difference between fluorescent UV lamp testing and xenon arc lamps?

Fluorescent UV aging chambers are capable of realistically simulating UV light. Polymers and their additives (e.g., antioxidants) react to 300-400 nm UV radiation from the sun. These photochemical reactions and condensation effects cause polymer degradation. This results in a loss of gloss, yellowing, and cracking. It also changes the material’s mechanical properties.

Window glass blocks most harmful UV rays (below 310 nm). So, use a fluorescent UV weathering chamber. It is best for testing outdoor exposure when structural changes in the polymer are a concern.

Xenon aging chambers are capable of realistically simulating the full spectrum of the sun. The right filters can accurately simulate sunlight in any setting. This means matching its wavelengths and their relative magnitudes. By setting the irradiance, humidity, rainfall and darkness periods it is possible to simulate the discolouration of the product that occurs under realistic conditions.

Xenon arc lamps are a good choice for the following situations:

– Colour loss assessment (fading of dyes and pigments)

– Materials that react to changes in humidity (textiles)

– Indoor exposure simulation (furniture or household products)

– Outdoor exposure simulation

3. What are the brands of UV weathering test chambers?

Natural sunlight and humidity can damage materials, causing immeasurable economic losses each year. UV weathering testers can replicate damage from sunlight, rain, and dew. The device tests the material. It exposes it to controlled cycles of sunlight and moisture. It also raises the temperature. The device uses UV fluorescent lamps to simulate sunlight. It can also simulate moisture through condensation or spray.

In just a few days or weeks, the device can reproduce damage that would take months or years outdoors. The main damage includes fading, discolouration, and loss of brightness. It also includes chalking, cracking, blurring, embrittlement, and oxidation. Lastly, there’s a loss of strength. The test data from the equipment can be very helpful. It can help select new materials or improve old ones. It can also assess changes that affect product durability. The equipment is a good predictor of the changes a product will encounter outdoors.

Ultraviolet (UV) light is only 5% of the sun’s rays. But, it is the main cause of outdoor products’ reduced durability. This is because the impact of photochemical reactions from sunlight increases as the wavelength decreases. So, when modeling the effects of sunlight on materials, only short-wave UV light needs to be modeled in most cases.

UV accelerated weathering testers use UV lamps. They are more stable than other lamps and reproduce test results better. Fluorescent UV lamps are excellent for simulating sunlight. They can test for brightness loss, cracking, and peeling.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]