How textiles age. It is the effect of heat, humidity, light, air, and other factors on textile properties. Textiles undergo these changes when they are used or stored. They include color and physical changes, such as breaking strength. The methods for testing textile aging now focus on light. The test standards and principles are as follows.

01 GB/T 16991-2008 covers the color fastness test for textiles.

It tests color fastness to light and aging at high temperature. It uses a Xenon arc lamp.

Here is the principle: expose the specimen to light. The light will be artificial and meet specified conditions. It will be with the blue wool specimen of grade 6 under the same conditions. We will rate the specimens for light discolouration resistance. We will use the grey sample card specified in GB/T 250 to assess discolouration. They will use the color testing apparatus specified in FZ/T 01024 to rate them. This apparatus is for rating light discoloration resistance. One can also evaluate the aging characteristics, such as physical properties.

02 GB/T 35256-2017 covers the color fastness testing for textiles.

It includes tests for artificial weathering. This involves exposure to filtered xenon arc radiation.

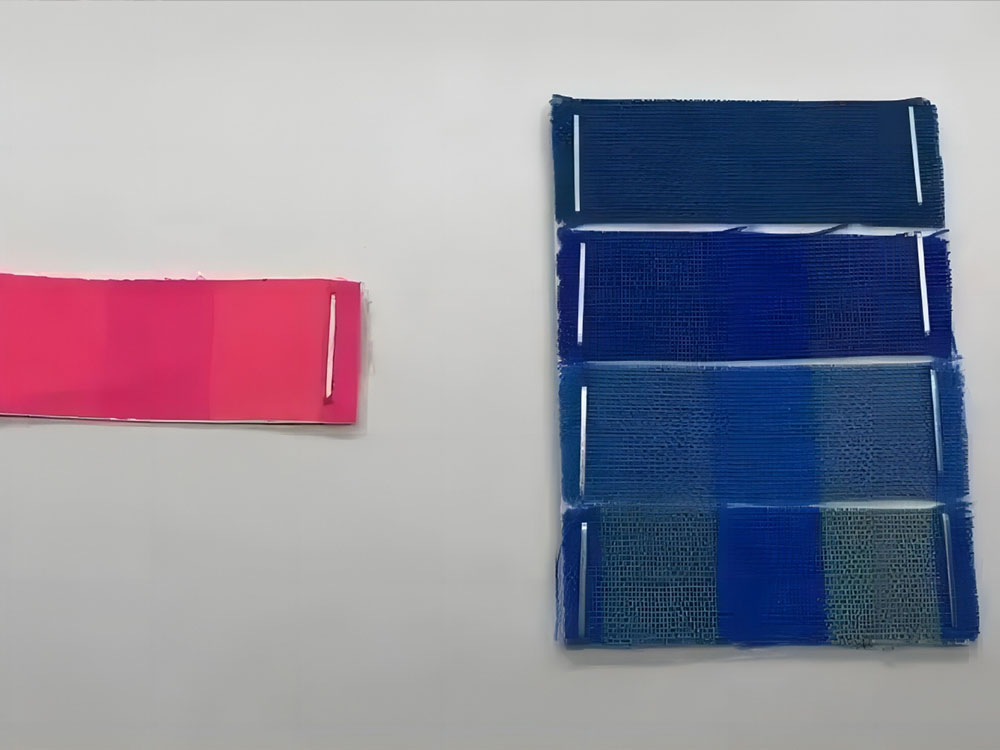

A xenon arc lamp exposes textile specimens. They may or may not get wet. We assess the colour fastness of the specimens using a grey card or a rating device. We test selected properties, like breaking strength, of the exposed and unexposed specimens. We test them separately. We use the right methods. We rate ageing performance based on the change in these properties. The ageing index is important for the textile sample’s end use. All parties agree on it.

03 GB/T 8430-1998 is about colour fastness tests for textiles.

It is about the fastness to an artificial climate: Xenon Arc.

Spray the textile specimen and eight blue wool standards. They are then exposed in a xenon lamp tester. This happens under set conditions. At the same time, the eight blue wool standards have glass to prevent misting. Then, compare the specimens with the blue wool standards. This is to assess the color fastness. It is not needed to expose the blue wool standard for wet photosensitive textiles. Instead, use the grey sample card to compare.

04 GB/T 31899-2015 Textile Weathering Test Ultraviolet Exposure

The technician places the specimen under the specified ultraviolet light. The light is fluorescent. The conditions include condensation and/or spray. Compare the performance change of the specimen after exposure with the original specimen.

05 AATCC TM186-2022 “Weather Resistance of Textiles: Wet Exposure to Ultraviolet Light”.

A UV light exposes the specimen. It is then humidified under controlled conditions. We assess the samples’ resistance to degradation by the percentage loss of strength. We also assess it by the residual strength. We compare the test specimen to the reference and exposure standards. We do this under standard textile test conditions. We use the resulting color change to measure resistance.

06 AATCC 169-2020 Weather Resistance of Textiles: Xenon Arc Lamp Exposure

Principle: Expose a sample of textile and a reference to a xenon arc lamp at the same time. This occurs under specific conditions. It is to assess how the test material resists degradation. It does this by comparing it with the reference.

07 ASTM G154-2023 “Operating Procedure for Fluorescent Ultraviolet Lamps for Exposure of Nonmetallic Materials”.

This standard is for specific exposure conditions. It also covers how to evaluate changes. The practices or methods define these for an application. This practice mimics weathering. Materials face sunlight and moisture during use. This exposure can be direct or through window glass. In controlled conditions, we expose samples to fluorescent UV light. At the end, we measure any changes in performance using recognised international standards.

08 ASTM G155-2021 Standard Operating Procedure for Xenon Arc Lamp Apparatus for Materials Exposure

This specification covers the basic principles and procedures for using xenon arc lamps. It also covers using water devices. Designers created these devices to recreate weathering. It happens when materials are in sunlight. This can be direct or through window glass. They are also in moisture from rain or dew. A filtered xenon arc lamp exposes the specimens. We control the conditions. At the end of the exposure, we measure changes in performance. We use recognized international standards.

There are different test conditions for each of the above aging criteria. Select them based on the textile’s use scenario and lifespan. We must also determine the evaluation method for the tests. The evaluation method should not only focus on appearance changes. It should also focus on changes in quality.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]