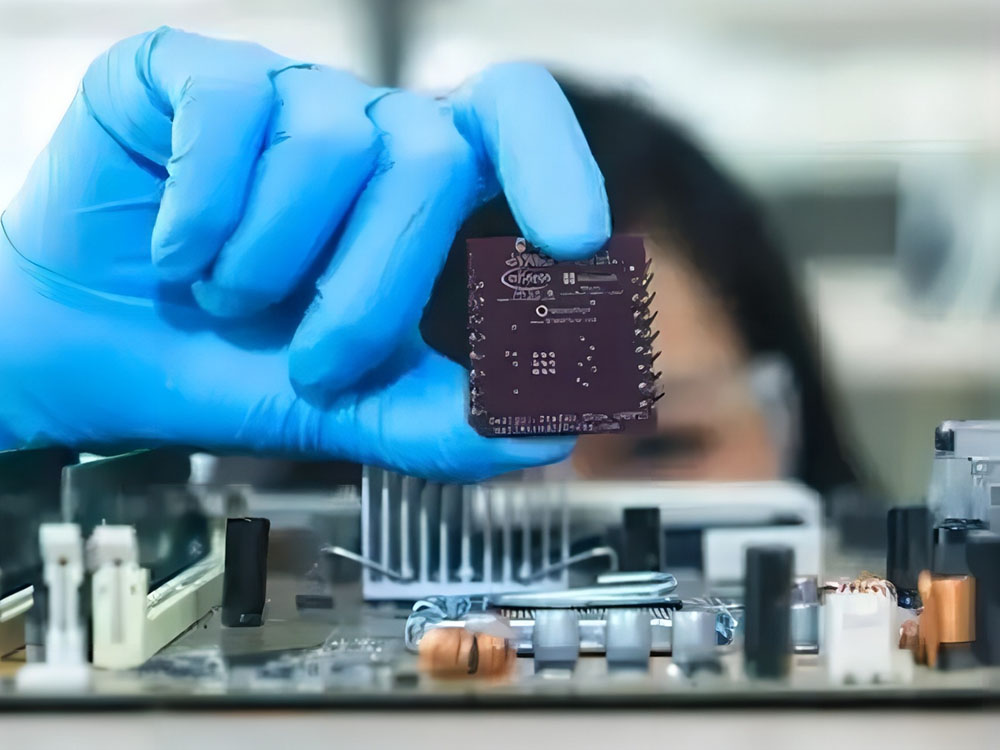

Science and technology are progressing. People use electronic products more frequently. So, they demand chip reliability more. Thus, aging tests are indispensable.

- Principle of chip aging test system

The IC chip aging test system is based on the physics of electronic device aging. It simulates the chip’s long-term working environment for testing.

During long use, the chip is exposed to unstable temperatures. It is also exposed to humidity, voltage, and other factors. These cause its internal devices to age. This aging degrades its performance or causes it to fail.

So, the aging test system simulates these factors. It checks chip aging by running the chip for a long time. It monitors changes in its performance indicators.

The key to chip aging tests is to pick the right aging signal and environment for testing.

Commonly used aging signals are high-temperature, high-voltage, and high-frequency. The common aging environment has a constant temperature. It also has thermal cycling and humidity and temperature cycling.

- Application of chip aging test system.

The IC chip aging test system plays an important role in the chip manufacturing industry.

The aging test assesses the chip’s reliability after long use. It gives chip makers an important reference for their decisions.

Also, aging tests can find chip problems. They let us solve or repair them early. This work improves product quality.

Also, aging tests can screen products. They exclude poor chips and ensure consistent, reliable products.

Also, chip designers can optimize the chip design using the aging test results. This will improve the chip’s durability and stability.

In short, an IC chip aging test system is vital in the chip industry.

Chips’ reliability and performance are assessed through aging tests. These tests simulate long-term use.

Aging tests can guide chip makers. They help ensure that product quality and reliability are ensured. They provide a reference for decision-making.

Chip aging test is important. It assesses chip reliability. This role is vital in the chip’s life cycle. Its effects the chip’s design, manufacture, and maintenance.

We use the chip-aging test to check how well a chip works and to guess its life. The test simulates the tough conditions the chip will face over a long period of time.

- Test Methods of the Chip Aging Test System

①High temperature aging test

Put the chip in a high-temperature place. The temperature is higher than normal. It is, for instance, 85 ℃ or 100 ℃. We’ve heated the chip for a long time to simulate a high-temperature environment. We do this to see if the chip’s performance is stable.

②High Voltage Aging Test

Apply a higher voltage to the chip. The voltage should be 1.2 or 1.5 times its normal level. By applying high voltage for a long time, we’ve found changes in chip performance indexes. This lets us assess the chip’s reliability in high voltage.

③High-frequency aging test

The chip will be run at a high frequency. The frequency will be several times its normal frequency. You use high-frequency operation for a long time. You do this to observe changes in the chip’s performance. This helps you assess the chip’s durability and stability.

④ Temperature and humidity cycle aging test

The chip is placed in a certain temperature and humidity. It is then cycled between high and low temperatures and humidities. This simulates the chip’s work. The environments have big changes in temperature and humidity. We’ve tested the chip’s reliability in hot, humid environments. We’ve done this by observing changes in chip performance.

⑤ Temperature aging test

Temperature is one of the main factors affecting the life of the chip. Heating the chip in a high-temperature environment can simulate its use over a long time.

The temperature aging test can be split into two types. One is at room temperature, and the other is at high temperature. Normal temperature aging tests use a constant temperature and humidity box. High temperature aging tests use a high-temperature greenhouse.

⑥ Damp heat aging test

Humid, hot air is one of the main factors that hurts chip reliability. Testing in high heat and humidity can mimic the moisture that hurts chips.

The test uses a constant temperature and humidity box. The test lasts more than 1000 hours.

⑦Voltage aging test

Voltage is an important factor for chip life. High-voltage tests can simulate chip aging under voltage stress.

Voltage aging tests generally use high-voltage power supplies, testing at a constant voltage.

⑧ Radiation aging test

Chips in high radiation will perform worse. You can test their performance by simulating the radiation environment. This lets you assess their ability to handle radiation and their reliability.

We conduct radiation aging tests with a radiation source. We use a test time and radiation energy as required to determine it’s.

⑨Mechanical aging test

Chips can be damaged by mechanical stress. Testing them under different stresses lets us assess their resistance and reliability.

Mechanical aging tests include impact tests, vibration tests, bending tests, and so on.

- Flow of chip aging tests.

The process of chip aging tests generally includes the following steps:

- Determine the purpose and test items of chip aging tests

Decide the test goals and content based on actual needs. This includes the test time, environment, stress factors, and so on.

- Design the chip aging test programme

Design the test program based on the chip’s characteristics and its stress factors. These factors include the type, level, time, and conditions of the stress.

- Implement chip aging tests

Follow the test plan to test for chip aging. Check the parameters and performance in the test.

- Analyze the results of the chip aging test

Analyze and process the test data to assess the life and reliability of the chip.

- Provide feedback and improvement according to the test results

Improve the design and making of chips based on the test results. This will boost the reliability and life of the products.

- Notes on chip aging tests

Testing chip aging is complex. You must pay attention to these points:

① Test parameters and environment should be accurate and reliable. In the chip aging test, you need to measure the test’s parameters and control its environment. This is to ensure the accuracy and reliability of the results.

② The design of the test programme should be reasonable and workable. When designing the test, consider the actual situation and test possibilities. Make a reasonable plan to ensure the test is effective and doable.

③ Test data should be accurate and complete records. In the chip aging test, it’s essential to record the test data well. This is needed to ensure the truth and reliability of the test results.

④The test process should pay attention to safety. During the chip aging test, it’s essential to focus on safety. Ensure that the safety of people and equipment is ensured in the test.

In conclusion, chip-aging tests are key. They assess chip reliability and lifespan by simulating many stress conditions. The conditions will occur during prolonged use. They provide vital guidance for chip design and manufacturing.

6.Summary

Only a good test program and accurate test data can improve a chip product’s life. They also ensure a product’s quality and stability.

We can only ensure that the data is statistically significant. We do this by choosing the right manufacturer. They must provide quality products for each test phase.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]