Manufacturers produce auto glass sunshade film as a type of plastic film product, mainly using polyester film and going through processes such as body dyeing, injection of ultraviolet absorber, coating, and laminating. This material is highly favoured by consumers because of its excellent heat insulation and sun protection. Auto glass sunshade film on the car idle cooling effect is more obvious, can reduce energy consumption, help energy saving and environmental protection . However, many consumers worry about automotive glass sunshade film performance deteriorating after several years of use, due to prolonged sun exposure. To address this issue, the industry has generally adopted two testing methods, outdoor exposure and xenon lamp aging, to verify the light aging resistance of automotive window shading films.

The outdoor exposure test is to directly expose the samples to the natural environment, subjecting the samples to the combined effects of various atmospheric factors to assess the product’s resistance to light aging. This test programme can fully verify the product’s ability to maintain sun protection and heat insulation performance under real use, but the test time is long, making it difficult to meet the needs of the enterprise’s new product development cycle. Xenon lamp aging test is through the environment simulation equipment to test the performance of the product decay of a method, through the control of sunlight radiation, ambient temperature, etc., to achieve accelerated aging effect. This method can simulate the natural environment for a number of hours through hundreds of hours of testing, and is a highly economical testing method.

There are various states of natural use and different test protocols for xenon aging, so finding the correlation between the 2 test protocols, outdoor exposure and xenon aging, is especially critical to aid in product development. To this end, this paper designs a test protocol, i.e., to test the optical properties of automotive glass sunshade film before and after the test by designing the typical use conditions of the product and the two commonly used xenon aging test methods, analyses the correlation between the two protocols, and puts forward some suggestions based on the test results. Manufacturers produce automotive glass sunshade film as a plastic product, mainly using polyester film and going through processes such as proprietary dyeing, injection of ultraviolet absorbers, coating, and lamination.

This material is highly favoured by consumers because of its excellent heat insulation and sun protection. Auto glass sunshade film on the car idle cooling effect is more obvious, can reduce energy consumption, help energy saving and environmental protection . However, the decay of automotive glass sunshade film performance after several years of use following prolonged exposure to the sun worries many consumers. To address this issue, the industry has generally adopted two testing methods, outdoor exposure and xenon lamp aging, to verify the light aging resistance of automotive window shading films.

The outdoor exposure test is to directly expose the samples to the natural environment, subjecting the samples to the combined effects of various atmospheric factors to assess the product’s resistance to light aging. This test programme can fully verify the product’s ability to maintain sun protection and heat insulation performance under real use, but the test time is long, making it difficult to meet the needs of the enterprise’s new product development cycle. Xenon lamp aging test is through the environment simulation equipment to test the performance of the product decay of a method, through the control of sunlight radiation, ambient temperature, etc., to achieve accelerated aging effect. This method can simulate the natural environment for a number of hours through hundreds of hours of testing, and is a highly economical testing method.

There are various states of natural use and different test protocols for xenon aging, so finding the correlation between the 2 test protocols, outdoor exposure and xenon aging, is especially critical to aid in product development. Therefore, in this paper, we design a test protocol to test the optical properties of automotive glass sunshade film before and after the test, analyse the correlation between the two test protocols by designing the typical use conditions of the product and the two commonly used xenon lamp aging test methods, and make some suggestions based on the test results.

1 Test programme

1.1 Outdoor exposure

The test time is 1.5 a, and we test the optical properties of automotive glass sunshade film at 0.5 a, 1.0 a, and 1.5 a respectively. We tested three samples in each group in two typical environments during the test: (1) with a sunshade, which had low light intensity and no rain; (2) without a sunshade, which had high light intensity and rain. We chose the outdoor exposure site in the Jinshan Industrial Zone in Shanghai, an area close to the sea, located on the roof of an open building with full access to sunlight and rain.

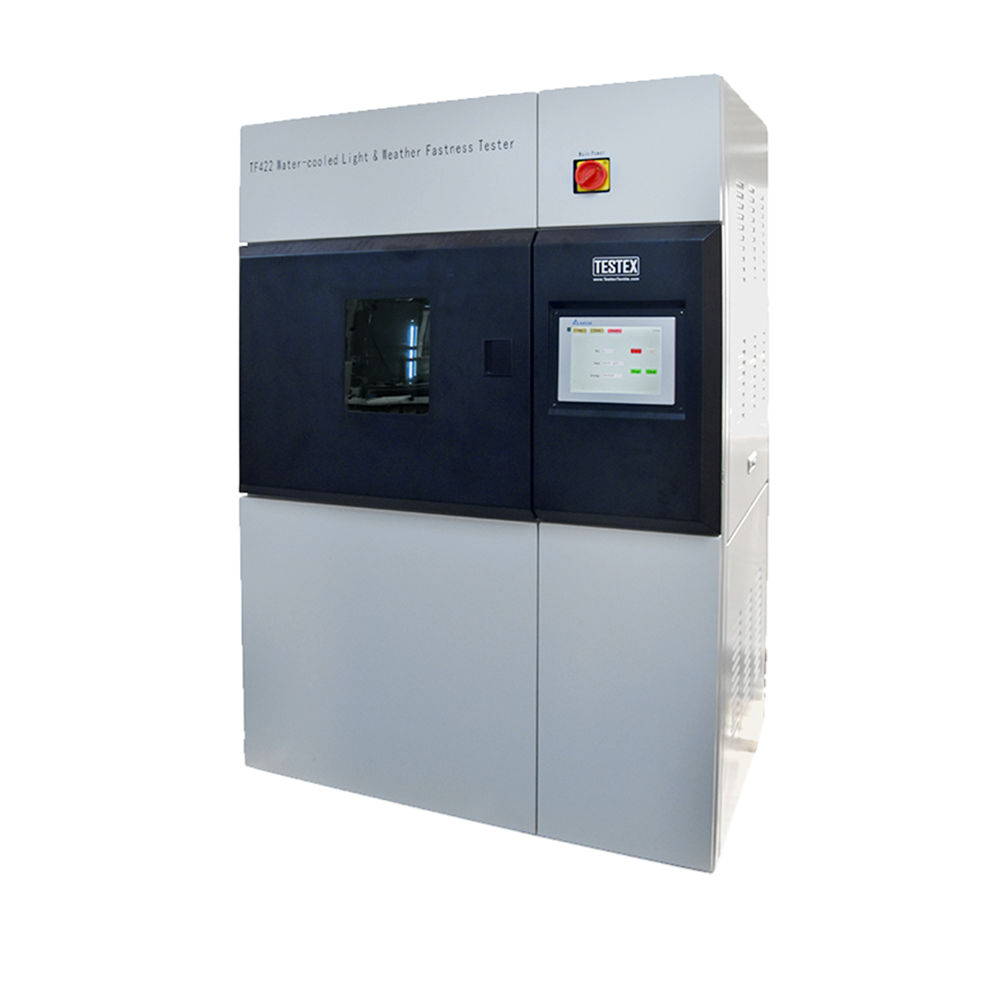

2 Xenon lamp aging

The test time is 600 h. We test the visible light transmittance and ultraviolet light transmittance of the samples at 200 h, 400 h, and 600 h, respectively. Each group tested three samples under the following test conditions: ① GA/T 744-2013 ‘Automobile Window Glass Sunshade Film’, with an irradiance of 0.55 W/m2 @340 nm, a black mark temperature of 63 ℃, a box temperature of 38 ℃, and no spraying; ② GB/T 1865-2009 ‘Artificial Climate Aging and Artificial Radiation Exposure of Colour Paint and Varnish’. GB/T 1865-2009 ‘artificial climate aging of paint and varnish and artificial radiation exposure filtered xenon arc radiation’ conditions, that is, irradiance 0.55 W/m2 @340 nm, the black standard temperature 63 ℃, box temperature 38 ℃, spray (spray 18 min after stopping the spray 102 min).

2 Test results and analysis

The two key indicators that affect the experience of using automotive glass sunshade film are visible light transmission ratio and ultraviolet transmission ratio. The higher the visible light transmission ratio, the better the transparency and driving vision it provides; the UV transmission ratio measures the transmitted UV spectral radiation flux compared to the incident UV spectral radiation flux, and because sunlight UV rays can be harmful to the skin and interior surfaces, a lower parameter is preferable.

The test results under outdoor exposure and shaded conditions correlate well with those of GA/T 744-2013 xenon lamp aging; the test results under outdoor exposure and unshaded conditions correlate somewhat with those of GB/T 1865-2009 xenon lamp aging.

(1) UV energy affects the optical properties of sunshade films.

UV energy destroys the main chain structure of organic materials. The main chain of sunshade films contains sensitive absorption bands in the UV segment, and catalysts from film production and impurities from transport also absorb UV. Xenon lamp aging can simulate the 290~800 μm band through the xenon light source, which covers the UV segment, and therefore can show correlation with the outdoor exposure programme.

(2) Ambient temperature and humidity affect the optical properties of sunshade films.

Elevated temperatures cause the molecules in the film material to move more vigorously, and once the kinetic energy of the molecules is stronger than the dissociation energy of their chemical bonds, the molecular chains will be thermally degraded. To address the effect of elevated temperature on sunshade films, we further validated by adjusting the box temperature based on the GA/T 744-2013 test protocol in a laboratory environment. During the validation test, we set the box temperature to 26 °C, 30 °C, and 34 °C, respectively, and compared the data with those at a box temperature of 38 °C. We set the box temperature to 30 °C, 30 °C, and 34 °C, respectively.

In addition, the effect of humidity on the membrane material is due to the fact that water can cause the material to swell or dissolve, resulting in a shift in the intermolecular forces, which does not ensure its initial aggregated state structure. Researchers use xenon aging to simulate a climatic environment similar to the natural environment in order to achieve test results similar to outdoor exposure. It can also be seen from the test data that the optical properties of the samples decay differently with and without shade.

(3) The amount of irradiation affects the optical properties of the sunshade film. The total energy of solar radiation refers to the cumulative radiant energy received per unit area of the sample surface over a period of time, which will directly affect the aging of the material. Shanghai has a subtropical climate, and the total annual solar radiation energy is 3,300-5,800 MJ/m2 . According to the xenon lamp aging equipment table shows the total energy, the total radiation energy of the test 600 h is 9 000 MJ/m2, the total energy of radiation is similar.

(4) Influence of the test samples’ bench conditions. Comparison found that the test results of outdoor exposure, no shade conditions and GB/T 1865-2009 xenon lamp aging test results have a certain degree of correlation, but the correlation is not as strong as the correlation between the test results of outdoor exposure, shade conditions and GA/T744-2013 xenon lamp aging test results. Certain factors affect the sample’s stand, as determined by judges. We applied the automotive glass sunshade film to the inside of the glass and conducted the test with the glass side facing up. In the laboratory environment, the steel plate test stand with good drainage helps evaporate or drain water from the film surface during spraying conditions.

However, we constructed the outdoor exposure test rig for this test out of wood, which absorbs more than steel plates, making it more likely for the film surface to collect rainwater or dew. As moisture will irreversibly affect the adhesive state of the automotive glass sunshade film, which in turn will cause changes in the optical properties.

3 Conclusion

Xenon lamp aging test has been widely used in the light aging performance test of various materials, which as an important supplement to the outdoor exposure test, can help to assess the natural aging ability of the product. For the Shanghai area, the correlation between the test results under outdoor exposure and shading conditions and those of GA/T 744-2013 xenon lamp aging is good, and the correlation between the test results under outdoor exposure and no shading conditions and those of GB/T 1865-2009 xenon lamp aging is certain.

However, we still need to consider the preference of xenon lamp aging compared to test results under outdoor exposure because xenon lamp aging tests simulate light, temperature, and humidity but cannot simulate airborne corrosion (e.g., acid rain), dust, and low-temperature environments in atmospheric conditions, all of which can also impact the aging of the samples. Future evaluations should include condensation test, neutral salt spray test, high and low temperature test, etc. to help verify the actual anti-aging capabilities of the products using this data.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]