As humans, we are always captivated by the power of sunlight. The ability of sunlight to nourish life and evoke emotions cannot be ignored. Also, it has technological innovations as well. In this natural phenomenon, scientists have turned to Xenon Arc Testing. It is a groundbreaking method that simulates sunlight in a controlled environment. This xenon testing holds the key to unlocking the secrets of sunlight simulation. It offers insights into material durability and reliability.

In this article, we will learn about weathering testing and its principles. You will learn the advantages and disadvantages of xenon testing.

Principles of Xenon Arc Testing

Xenon arc testing is a form of weathering test. It is a crucial component for testing the durability and longevity of products. It can simulate the effects of sunlight, moisture, and heat. This testing is an invaluable tool for assessing how materials withstand outdoor conditions. When materials are subjected to xenon arc weathering tests, they undergo xenon light. The materials undergo testing in fluctuating temperatures and intense light.

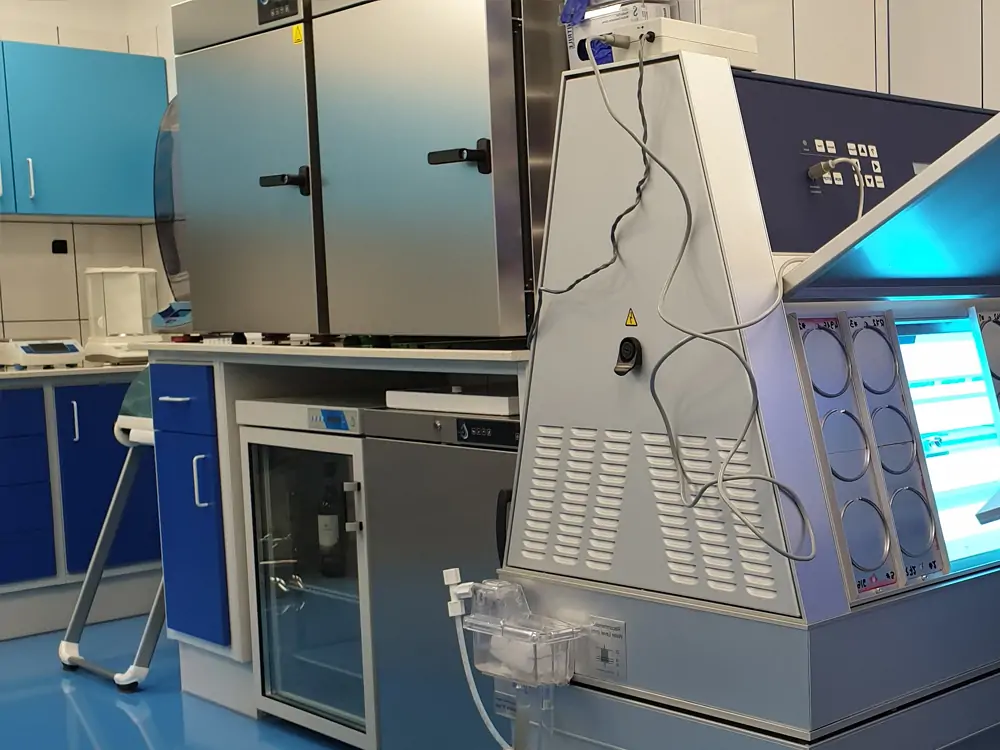

Xenon Arc Testing Equipment

Performing xenon testing requires equipment to ensure controlled sunlight exposure. The following are key components and essential xenon arc testing equipment:

Xenon Arc Lamps

Xenon arc lamps produce a wide range of light. This includes UV, visible, and infrared radiation, just like sunlight. These lamps emit strong light to mimic outdoor conditions for testing materials.

Xenon Lamp Housing

The protective housing encases the xenon arc lamps. This keeps them safe and controls exposure conditions. It shields operators from the intense light. It creates a controlled environment for testing.

Specimen Holders

Test specimen holders secure and position the specimens during the weathering test. It ensures consistent and repeatable conditions. This also prevents the specimens from moving or deforming. Thus, it helps to maintain reliable test results.

Light Filters

Xenon arc lamps have light filters added to change the light they produce. These light filters can target specific wavelengths or remove others. This changes the light to make testing more specific for certain materials.

Environmental Chambers

Environmental chambers control xenon arc lamps and specimens. This is to regulate temperature, humidity, and other conditions. They simulate outdoor conditions for testing.

Cooling Systems

The cooling systems prevent the xenon arc lamps from getting too hot during testing. This keeps the testing chamber at a stable temperature. Also, it prevents damage to the specimens.

Radiometer/Photometer

Radiometers measure all the light from xenon arc lamps. Photometers measure only visible light. They check and maintain the accuracy of light levels during testing. This helps ensure reliable results.

Temperature Sensors

Temperature sensors in the testing environmental chamber measure temperature changes during testing. They give real-time data on temperature. It makes adjustments and keeps the testing conditions consistent.

Humidity Control Systems

These humidity systems control humidity in the chamber to mimic different environments. It is easy to adjust the humidity levels. Because it is important for testing materials in varying moisture.

Data Acquisition Systems

These data acquisition systems collect and record data. They collect data on light intensity, temperature, and humidity. Researchers analyze the performance of the materials.

Safety Features

There are various safety features. These include emergency shut-off systems, protective barriers, and warning alarms. it is important to keep operators safe and prevent accidents during tests. This makes the environment safe for testing for everyone.

Applications of Xenon Testing in Various Industries

1.Automotive Industry

Xenon arc testing is used in the automotive industry. It tests various components in automobiles. This includes exterior paints, plastics, and rubber. It protects the durability of materials against sunlight exposure.

2.Textiles and Fabrics

Outdoor textiles, such as those used for awnings and outdoor furniture. They are also exposed to sunlight. Manufacturers use this weathering test to test how these materials resist fading damage.

3.Construction Materials

Construction materials like paints, coatings, and sealants undergo this test. It tests how these materials can handle outdoor environments. This helps make sure that buildings and structures last a long time and stay strong.

4.Electronics and Plastics

Electronic device components and plastic materials also undergo weathering tests. It detects how these materials can hold up to sunlight aging. This is important for making sure the devices work well and are reliable.

Advantages of Xenon Arc Test

Xenon testing is important to test materials. It has several advantages that are as follows:

- It provides a simulation of outdoor conditions by replicating the sunlight spectrum. This includes visible, IR, and UV.

- Xenon testing has versatile applications. It ranges from polymers and coatings to metals and textiles.

- Xenon testing is useful for fast testing of material durability. It processes faster than natural weathering.

- This testing provides a comprehensive assessment of the endurance of materials. This includes factors like humidity, temperature, and sunlight.

- It ensures quality control and quality assurance. It identifies the vulnerabilities in the production process. Thus, prevents the release of substandard products.

- Xenon testing is cost-effective because it goes in the long run. It gives accelerated evaluations of the durability of materials.

- It complies with international standards. It ensures consistency and comparability of the results in industries.

- It allows monitoring of tests. This contributes to detailed insights into material behavior.

Disadvantages of Xenon Arc Testing

Besides advantages, xenon arc weathering testing also has disadvantages that are as follows:

- Xenon testing does not consider the outdoor conditions. These factors include rain, temperature, and wind.

- It requires large equipment costs. The maintenance and purchase of xenon arc lamps are expensive.

- It has high operational costs. High operational cost is due to humidity and temperature control.

- It requires a large space for conducting xenon arc testing. It limits the feasibility of smaller laboratories.

- Weathering testing lacks natural variations during outdoor exposure leading to limitations.

- Xenon arc testing is resource-intensive. It requires careful monitoring and calibration for accurate results.

- The environmental chambers can cause contamination. This affects the results of material durability.

- It interferes with other external sources of light. It requires additional measures to mitigate these interferences.

- It has limited specificity because of the UV resistance which is a primary concern.

Advancements in Xenon Arc Weathering Testing: Illuminating the Path Forward

Businesses are pushing for more innovation in xenon arc testing. They want to make sure their products can withstand different conditions. This has changed how we do xenon testing, opening up new ways to see how sunlight affects materials. It is important to create xenon light sources that mimic sunlight. This helps researchers and engineers learn about the reaction of materials. This reaction is due to long-term exposure to various conditions. This includes humidity, sunlight, and temperature changes.

New data analytics and machine learning have improved the xenon arc weathering test. They check and analyze test samples in real time. This gives detailed information on materials. It tells about degradation patterns, material aging, and photochemical reactions. These tools help researchers find weaknesses and areas for product design improvement.

Conclusion

In conclusion, xenon arc testing is a powerful tool for evaluating how sunlight affects materials. It is used in industries like automotive and construction. Because it can simulate sunlight, is versatile, and can test materials. As industries grow and consumer demand increases, the need for durable materials grows. The weathering test can shed light on the performance of the materials. This occurs in simulated outdoor conditions. It plays a pivotal role in ensuring products withstand the test. Whether it is the fading resistance of textiles or automotive components. This method illuminates the path towards material durability. In the future, as technology advances, Xenon arc testing will likely improve. These improvements will make the simulations more accurate. Also, it will help us understand how materials age. The weathering test will continue to guide industries in developing quality products. Those developed products will withstand various environmental conditions.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]