An industrial oven is a drying equipment widely used in industrial production. Its performance and service life directly affect production efficiency and product quality. To protect the stable running of the industrial oven and prolong the service life. Routine servicing is essential. Maintenance is a necessary measure for ensuring that industrial ovens continue to operate. Only based on doing an excellent job of these tasks. It improves the equipment service life and ensures the production’s safety and reliability.

The maintenance of industrial oven equipment requires attention to the following points:

Cleaning and maintenance

Ensure the industrial materials baked in the oven are dry and clean. So we need to clean the industrial oven’s surface and the dust’s inner cavity. We also need to ensure the cleanliness and sanitation of the machine at all times.

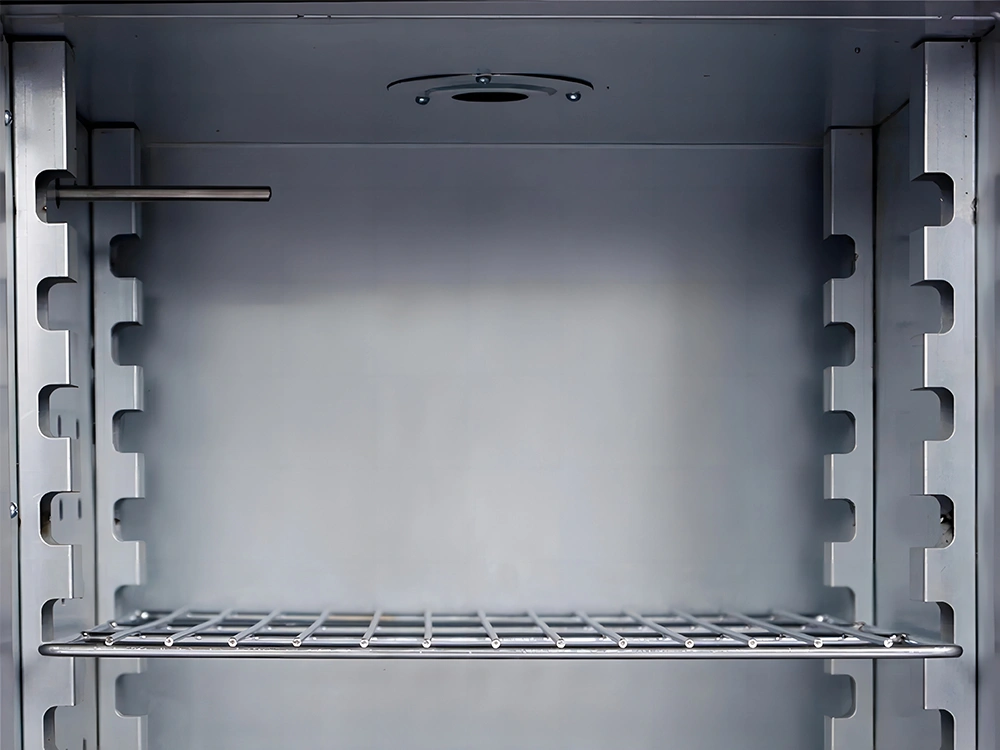

Clean the inside and outside of your industrial oven regularly. This cleaning includes heaters, fans, control panels, and other components. Remove dust and impurities and ensure that the equipment is well-ventilated. Periodically clean the baking trays and grids of your industrial oven. Avoid residue affecting the baking effect and equipment life. Clean the control panel and sensors regularly. Avoid dust and debris from affecting the proper running of the instrument.

When using the oven, it accumulates a great deal of dirt and dust inside the unit. Thus, you need to clean it regularly to remove dirt and dust from the inside. Use a soft cloth and neutral detergent—or high-temperature steam cleaning when cleaning. Avoid using cleaners containing corrosive substances such as acids and alkalis. Also, the filter needs to be changed regularly. Ensure the smooth flow of industrial oven air.

Regularly lubricate the lubrication parts of the oven equipment, such as fan bearings, transmission chains, etc. Reduces abrasion and noise, and prolongs the lifetime of the machine.

Checking electrical components and circuits

Check the electrical circuits of your industrial oven equipment regularly. Safeguard the circuit for proper operation. If a problem is found with the circuit, it must be fixed or changed promptly.

Examine the electrical components of your oven unit regularly. This includes wires, outlets, switches, etc. Ensure that they work correctly and replace damaged parts in time. To prevent electrical faults from causing fires and other safety issues.

Always check whether the current of the ammeter is regular. If the current is not normal, short-circuits and other situations are easy. If there is any abnormality, notify a maintenance specialist to repair it. So you can avoid unnecessary inconvenience.

Regularly check wires and cables for deterioration or aging and change them on time.

Check that power plugs and sockets are tight. Avoid malfunction caused by poor contact.

Ensure that the equipment is well grounded. Prevent electric shock and other safety accidents.

Check the sensor and control panel

You should regularly check whether the sensor and control panel work properly. If there is any abnormality, repair or replace it in time.

Regularly calibrate the sensor. Ensure the precision of temperature and humidity control of the equipment.

Check whether the keys and display of the control panel are normal. If there is an abnormality, handle it promptly.

Replacement of consumables

Regularly replace the industrial oven baking pan, mesh, and other consumables. Make sure that the equipment operates properly.

Replace seals and lubricants regularly. Make sure the unit is sealed and lubricated.

Replace damaged parts and wires to avoid equipment failure and safety hazards.

Regular replacement of the heater in the industrial oven equipment is necessary. Ensure that you heat up the machine. When replacing the heater, choose the same model and specifications as the heater—and replace it according to manual requirements.

Spare some perishable accessories, such as heaters, fans, pressure gauges, etc.. To replace the equipment in time when there is a problem.

Regularly check the industrial oven machine parts

When used, the equipment machine parts will wear and tear and fail. Thus, it must be regularly examined and maintained. For example, check the heater, fan, temperature controller, and other accessories. Confirm whether they are in abnormal conditions. Timely replacement or repair of equipment parts can prolong service life.

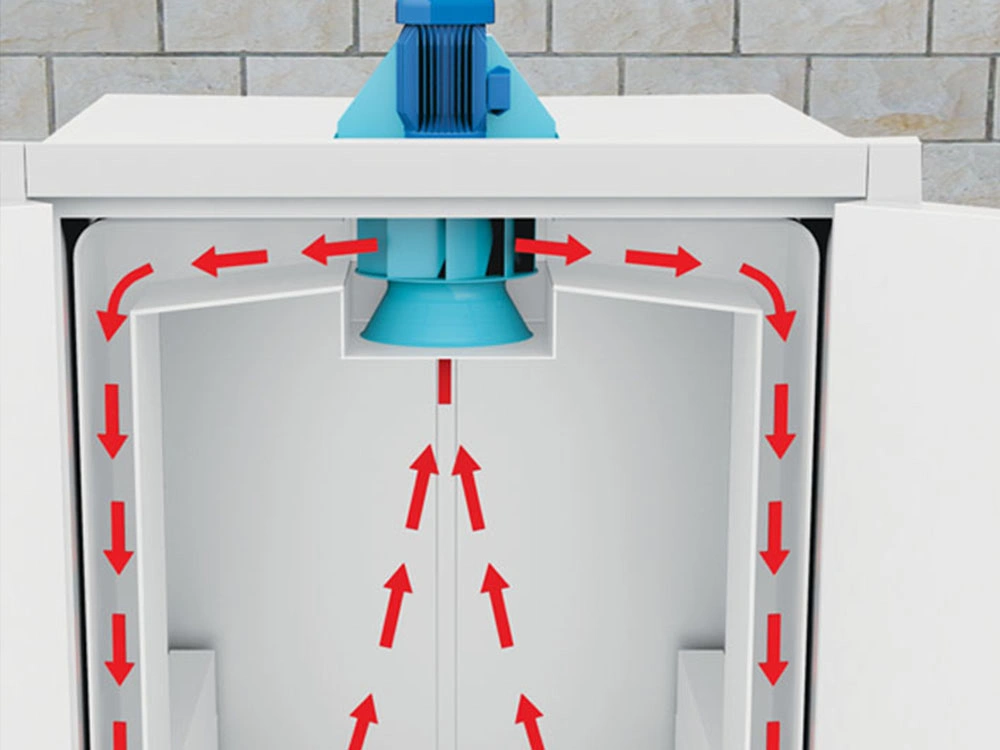

Check whether the fan is running normally. Because abnormalities in the fan may lead to the water vapor inside the oven can not be discharged in time. This will affect the drying effect. Maintain the fan of the industrial oven equipment regularly. To ensure that the fan works properly. If the fan is found to be defective, it must be fixed or changed on time.

Regularly check the pressure gauge of the industrial oven equipment. To ensure that the pressure gauge works properly. When you find that the pressure gauge is faulty, you must promptly repair or change it.

Periodically examine the temperature control system for the oven equipment. This includes temperature sensors, temperature controllers, etc. Ensure accuracy and reliability. It guarantees the baking quality and safety of your products.

Make Sure the Equipment Meets the Specifications

Need to ensure that the use of equipment is in line with the relevant safety standards. For example, electrical safety and mechanical safety. Also, care needs to be taken to insulate and ground the oven equipment. Avoid safety accidents.

Use non-explosion-proof electric ovens, and strictly prohibit bringing volatile objects into the oven.

Observe and adjust the oven temperature at all times. The temperature is to match the demands of the baking process.

If there is a sudden power failure, turn off the heating switch of the industrial oven. This prevents accidents when it is activated during an incoming call.

Has the equipment been serviced and maintained regularly by a professional? Keeps equipment in working order.

With the above maintenance and care, it can effectively increase the lifetime. Ensure the stability and reliability of your machine. At the same time, it can reduce equipment failure and maintenance costs. Improve production efficiency and product quality. Thus, regular servicing and maintenance is suggested. Make sure that the machine operates properly and lasts for the life of the machine.

Industrial oven safety regulations

- The equipment must be operated, repaired, and maintained;

- Operators need to carry out safety training and must be licensed. And study the electric oven “instruction manual”. Learn the basic structure and function of the machine. Become proficient in the operation program. Moreover, it must operate strictly following the regulations of operation;

- The operator should dress in working clothes, the sleeves should not be too long, and wear a job hat;

- Electric oven power consumption to prevent wire overload. You must use a separate line power supply. Install suitable fuses and use high-temperature-resistant insulating materials. And add a leakage protector;

- The heating equipment and power lines are to be checked daily. Power supply leads must not have exposed wires and other conditions. Electric plugs and sockets must be intact;

- It is strictly prohibited to open the power switch with wet hands to prevent electric shock;

- The electric oven will be placed in a dry, flat place on use, and make sure to keep enough space around it. Keep a distance of at least 10-15 cm from the surrounding objects;

- It is strictly prohibited to pull the power cord. Unplug the electric oven before moving it. And use both hands to move the oven;

- You cannot use the electric oven or place it near flammable materials. Keep away from drapes, curtains, or similar products when using to avoid fire. You cannot place any objects on top of the box when the oven is working.

- Please do not place closed containers in the oven to heat; otherwise, there may be a risk of explosion;

- For heating items, the container should reserve enough space. Prevent the liquid from boiling overflow;

- To avoid burns when the oven is working, only use the knob or handle.

- Please use a soft, damp cloth to clean the door. Do not use sharp cleaning instruments to prevent damage to the door glass;

- After completing the operation, you should close the oven power switch and the main power supply.

Summarize

Industrial ovens are important production equipment. It is widely used in industrial production. Preserve the proper functioning of mechanical machines. Must strengthen its maintenance and maintenance.

Daily maintenance and upkeep will help us find equipment problems in time. This will help us to prevent production from progressing and create hidden issues. Proper maintenance is the only way to prolong the life of your machine. Proper maintenance is the only way to extend the life and ensure it operates properly.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]