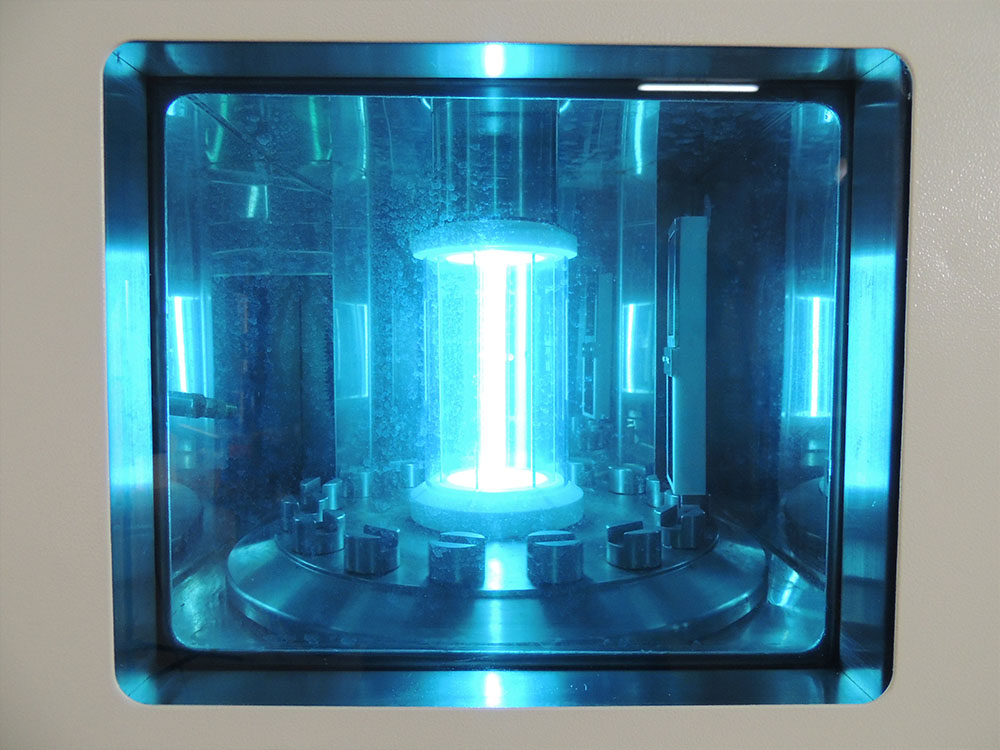

Why does the water-cooled xenon lamp aging tester lamp not light up?

The water-cooled xenon lamp aging tester‘s lamp does not light. This may be due to:

Water pump problems:

Check whether the water pump is working properly. If the pump does not work, it may be a power problem or the pump itself is damaged. Use a multimeter to measure the resistance of the water pump, the normal value should be about 1060 ohms. If the resistance is abnormal, it may damage the pump and require replacement.

Power problem:

Check whether the power supply is normal. Use a multimeter to measure whether there is 380V AC input and check whether the DC output is about 600V. If the power supply does not provide DC output, someone may have damaged it and will need to replace it.

Wiring and connection problems:

Check if someone has loosened the wiring. Also, check if someone has fixed the copper rods at both ends of the lamp. If the power supply is normal but the lamp does not light up, the wiring may be poorly connected.

Trigger problem:

Check whether the trigger relay KA6 on the switchboard has about 1 second of suction. If there is no suction, or if the trigger makes a sound but does not light the lamp, the damage may be in the trigger. Someone needs to replace it.

PLC problem:

If you hear the trigger sound but the lamp won’t light, check if the PLC is sending a voltage to the lamp power supply. Use a multimeter to check for a 5V DC input at the regulation input. If there isn’t one, there may be a problem with the PLC program or a damaged PLC module.

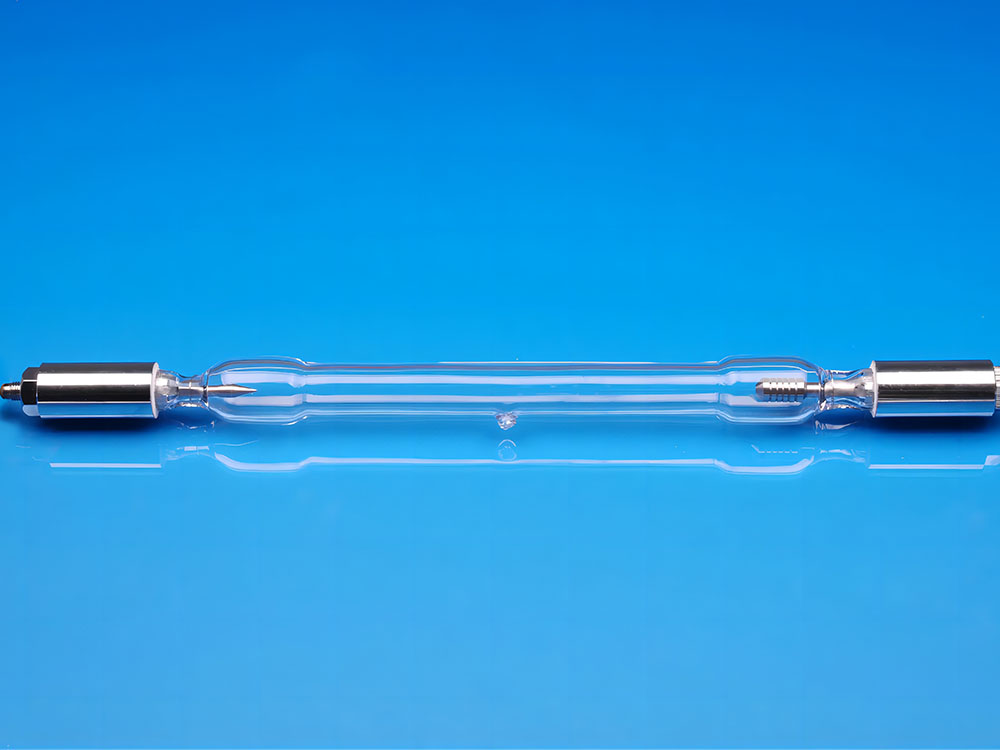

Xenon lamp itself:

If all the checks are normal, but the lamp won’t light, you may have a damaged or expired xenon lamp. You need to replace it.

Solution Steps:

Check the water pump:

Check that the water pump works. Measure the resistance and power supply. They should be normal.

Check the power supply: Measure the AC and DC outputs to see if they are normal.

Check the wiring connection: make sure all connections are firm and error-free.

Check the trigger relay: make sure the trigger relay is working properly.

Check PLC: Make sure the PLC output voltage is normal.

Replace the xenon lamp: If all the above are normal, try to replace the xenon lamp.

Why does the lamp of water-cooled xenon lamp aging tester flash?

The flickering of the aging tester for water-cooled xenon lamps may be due to:

Ballast problems: A faulty ballast is a common cause of xenon lamp flicker. If there is a problem with the ballast, it may cause the xenon lamp to flicker frequently. The solution to this problem is to replace the ballast with a better quality one.

Faulty wiring harness:

A faulty or unstable connection in the wiring harness for the xenon lights can cause them to flicker. Check the harness connection. It must be stable. Replace it if damaged.

Voltage stability:

Fluctuations in voltage can affect the xenon lamp and cause flickering. Voltage can be stabilised by installing capacitors to reduce flickering.

Bulb problems:

Problems with the bulb itself, such as a faulty or ageing bulb, can also cause flickering. Replacing the xenon bulb with a brand new one may be the solution to this problem.

Decoding errors:

Decoding errors may cause the xenon lamp to work improperly and flicker. You can fix decoding errors by reflashing the relevant software.

Cooling system problems:

If the cooling system (such as the water pump) is not working properly, it may also cause the xenon lamps to flicker. Check the working condition of the water pump to ensure that it is functioning properly.

Ways to fix these problems include:

Checking and replacing the ballast:

If the ballast is faulty, replace it promptly with a better quality ballast.

Checking the wiring harness connections:

Ensure the wiring harness connections are good. Replace damaged harnesses if needed.

Install capacitors:

Install capacitors to stabilize the voltage. They will reduce voltage fluctuations on the xenon lamp.

Replace the bulb: If the bulb is faulty or old, replace it with a brand new xenon bulb.

Reflash software: Fix decoding errors by reflashing the relevant software.

Check the cooling system:

Ensure that the cooling system (e.g. water pump) is working properly and repair or replace it if necessary.

Why does the water-cooled xenon lamp aging tester not work?

A water-cooled xenon lamp aging tester may not work for these reasons:

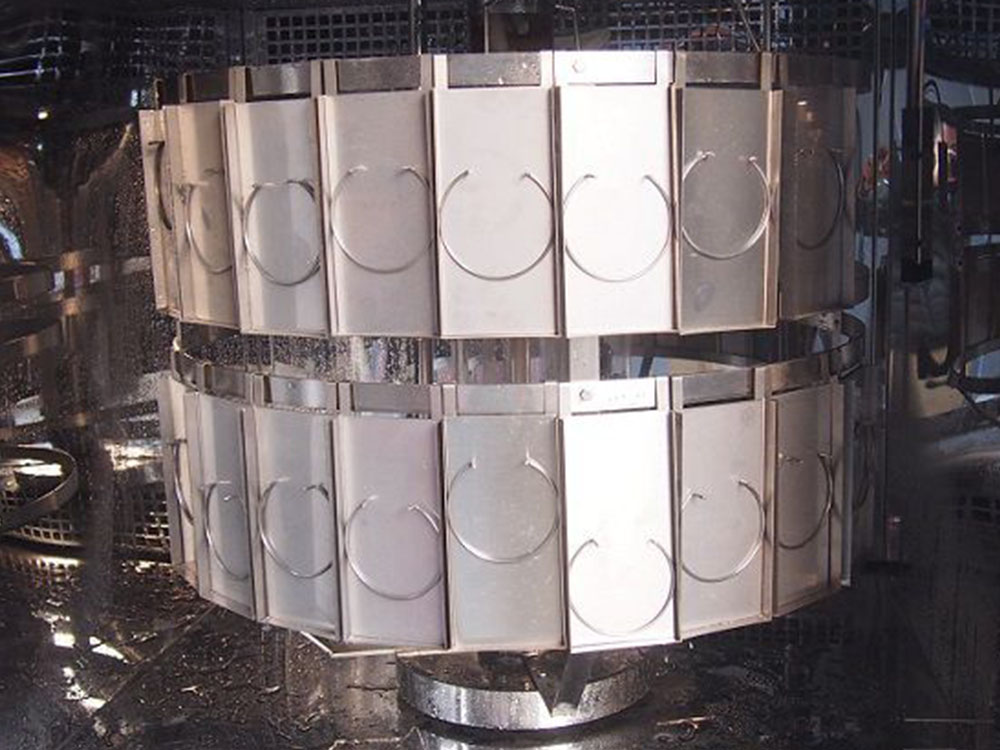

Cooling system failure:

The cooling system of the water-cooled xenon lamp aging tester is key. If the cooling water is impure or the system is faulty, it can cause overheating. Issues like a broken water pump or damaged water circuit can lead to this. Overheating will affect the tester’s normal operation.

Lamp and filter problems:

Water-cooled xenon aging tester lamps and filters need regular maintenance and replacement. A faulty lamp cartridge, a bad filter, or impure cooling water will reduce the lamp’s life and test results.

Improper operation and maintenance:

If the operator does not use and maintain the equipment as instructed, the test chamber will fail. For example, the lighting or instrument settings may be wrong, or the pump may not work.

Advantages of water-cooled xenon lamp aging test chamber include:

High brightness:

Xenon lamps can provide a bright light. They simulate a real-use environment.

Long life:

The tester’s xenon lamp is water-cooled to dissipate heat. This extends the lamp’s life and the tester’s.

High stability:

You can adjust the test’s internal temperature, humidity, and light as needed. This will ensure the test results are stable and reliable.

Easy to operate:

Equipped with various control and monitoring tools, it’s easy to use.

Why can’t we open the water-cooled xenon lamp aging test chamber?

The main reasons a water-cooled xenon aging tester cannot open the door during operation are:

Heat escape:

Xenon lamps produce a lot of heat when in use. Frequent door openings will let the heat escape. This will cause unstable temperatures in the test chamber, affecting test accuracy.

Light leakage:

Researchers use xenon lamps to simulate the full sunlight spectrum. Frequent opening of the chamber door will cause light leakage. This will affect the stability of the light source and the test results.

Safety Risks:

A high temperature test will release hot gas from the chamber. This may scald the operator. A low temperature test may cause frostbite from a sudden opening of the chamber door.

To ensure safe use and a long life for the water-cooled xenon lamp aging tester, follow these operation and maintenance guidelines:

Unpacking inspection:

Before use, check the equipment for any damage from transport. Also, confirm that all accessories are complete and undamaged.

Installation location:

The equipment should be in a well-ventilated, vibration-free area. It must be away from heat sources, flammable items, and chemicals.

Grounding:

Ground the equipment. This prevents injury from static or leakage.

Preparation before operation:

Verify that the water supply system connects and meets the requirements. Also, check the equipment’s power supply. You should connect it and set it to the right voltage.

Precautions during operation:

Check the test chamber’s temperature, humidity, light intensity, and other parameters. They must meet the test requirements.

End the test:

Switch off the equipment’s power supply. Remove the samples from the box. Clean the interior to ensure there is no residue in the box.

Can I take out the samples as soon as the xenon lamp ageing tester stops running?

Do not take out the samples immediately after stopping the Xenon Lamp Ageing Tester. The tester will simulate specific conditions (e.g., high heat, humidity, and light) when it runs, especially in aging tests. These will affect the samples. When the tester stops, the sample may still be aging. The test environment has changed. Immediate removal may affect the test results.

Operation procedures and precautions for xenon lamp aging tester

Equipment Inspection:

Ensure the equipment works. Check that all connections are normal, including the power and grounding.

Sample Preparation:

Place the sample to be tested on the sample rack inside the tester. Follow the requirements. Ensure the sample surface is clean and unobstructed.

Parameter Setting:

Use the control system to set the temperature, humidity, light, and spray cycle. Also, set the other parameters.

Programme editing:

Select or create a new test program. Include a light cycle, a dark cycle, a temperature change, and a humidity change.

Start Test:

After confirming that all settings are correct, start the test chamber. This will run the program. Monitor the parameters during the test to ensure they follow the preset program.

End of Test:

After the programme, stop the chamber and remove the sample. Then, evaluate the sample and record the test results.

Equipment Maintenance:

After the test, clean and maintain the equipment. This will ensure it is ready for the next test.

Does the xenon lamp aging tester emit radiation?

Xenon lamp aging test chambers do not produce radiation under normal use. Xenon lamp aging test chambers simulate solar radiation. They use xenon lamps to generate UV and visible light spectra to age products. Xenon lamps produce radiation. But, under normal use, the xenon lamp aging tester has a special isolation plate inside it. This plate effectively isolates the radiation. The tester is usually used in a special test chamber. The irradiated area has a closed, safe environment. So, it generally does not impact humans or the environment.

Xenon lamp aging test chamber working principle and scope of application

Xenon lamp aging test chambers simulate sunlight, including UV and visible light. They use xenon lamps to generate the light spectra. This better simulates natural light conditions. The goal is to use a xenon lamp to generate UV, visible light, and other radiation. A light filter will then process this light. The spectrum reaching the specimen should be close to the solar spectrum. The xenon lamp aging tester tests various materials, like textiles, cosmetics, and electronics. It can simulate different conditions, such as light, rain, and temperature changes.

Safety Precautions for Use

The xenon lamp aging tester emits a small amount of radiation. So, please note the following points:

When using the xenon lamp aging tester, isolate the irradiated area.

Do not observe the xenon lamp directly to avoid UV damage to the eyes.

Confirm that the test parameters meet the requirements.

Watch the equipment when the xenon lamp aging tester opens and closes.

What is the function of the xenon lamp aging tester?

A xenon lamp aging tester simulates light, temperature, and humidity. It tests how materials or products hold up after long use. Specific roles include the following aspects:

Material Weathering Test:

Simulate the UV and visible light from xenon lamps. Then, expose materials to prolonged light. This will test their durability and lifespan. We can test materials for colour change, chaffing, and strength loss. We will check for other ageing issues.

Product performance evaluation:

A xenon lamp aging test chamber can fully evaluate a product’s performance. For example, in the automotive industry, engineers can test old plastic parts of vehicles. They assess their weathering and durability.

New material research and development:

For new materials, a xenon lamp aging test chamber can help researchers. It tests the materials’ performance in a light environment. This lets them adjust the formula or processing to improve quality and stability.

Quality control:

Use xenon lamp aging test chambers for quality control. They ensure products are durable and stable under normal use. The aging test lets you track the product’s performance. You can then adjust and improve it as needed.

Wide range of applications:

The xenon lamp aging tester has a wide range of applications in many fields. For example, in the automotive industry, it can be used to assess the light resistance and colour stability of automotive interior and exterior, lampshades and plastic parts; in the field of building materials, it can be used to test the weathering performance of aluminium profiles, coatings and other building materials; in the electronics industry, it can be used to test the durability and stability of electronic products (such as mobile phones, TVs, computers, etc.).

What is the effect of xenon lamp aging tester on materials?

Xenon lamp aging testers mainly affect materials in these ways:

Simulation of full-spectrum sunlight:

Xenon lamp aging testers use xenon arc lamps. They simulate full sunlight. These lamps emit light close to that of natural sunlight, including UV, visible, and IR light. This light source is very comprehensive. It lets the tester simulate sunlight’s effects on materials. So, it can reproduce different environments and seasons. This simulation is vital for testing materials’ weatherability in the outdoors.

Highly adjustable:

The chamber has a high-tech climate control system. It can simulate a wide range of conditions, from extreme cold to heat. The user can also adjust parameters, like light intensity, to test different materials and products. This high adjustability lets the chamber be used in many aging test scenarios. It improves test flexibility and accuracy.

High stability and efficiency:

The xenon lamp aging tester has a very stable light source. It also has a precise temperature and humidity control system. This maintains a stable test environment. This is essential for long-term ageing tests and helps to reduce errors in test results. The chambers usually have a large testing capacity and fast speed. They can test multiple samples at once, improving efficiency.

Wide range of applications:

Xenon lamp aging test chambers have a wide range of applications in a number of fields. For example, in the auto industry, it can test the light and color stability of car interiors, exteriors, lampshades, and plastics. It can test the weathering of aluminum, coatings, and other building materials. It can test the durability of products like mobile phones, TVs, and computers.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]