In the world of testing and evaluating the durability of materials, there are 2 tests: Thermal Shock vs. Thermal Cycling Tests. These tests are easy to understand how car parts, ceramics, and electronics work. Even though these tests look similar, they have different reasons. Plus, they perform functions in different ways. In this article, we’ll explain these tests in an easy way and help you decide which one is best for what you need.

Understanding Thermal Shock Testing

Thermal shock tests check if a material can handle quick temperature changes. There are some shifts like high to low temperature. Then, from low to high temperature. These sudden shifts can cause stress and damage like cracks or fractures. The main goal is to see how well a material handles these big temperature swings.

What is the Thermal Shock Test?

In this test, a sample stimulates to the conditions of the real-world. This includes the cold and the hot environments. These testes help to replicate the different situations that induce stress. This disturbs the lifespan of the material due to temperature change. These changes occur in heating or cooling cycles in electronic devices. Also, in the components of automotive engine.

Purpose of Thermal Shock Testing

Shock tests are crucial in ensuring the reliability and durability of various materials. For example, in electronics, there are different components like semiconductors and circuit boards. They undergo extreme changes in temperature due to thermal cycling. This helps the manufacturers to check the material’s ability to hold thermal stress. In automotive industry, this test method undergoes thermal changes to check engine parts.

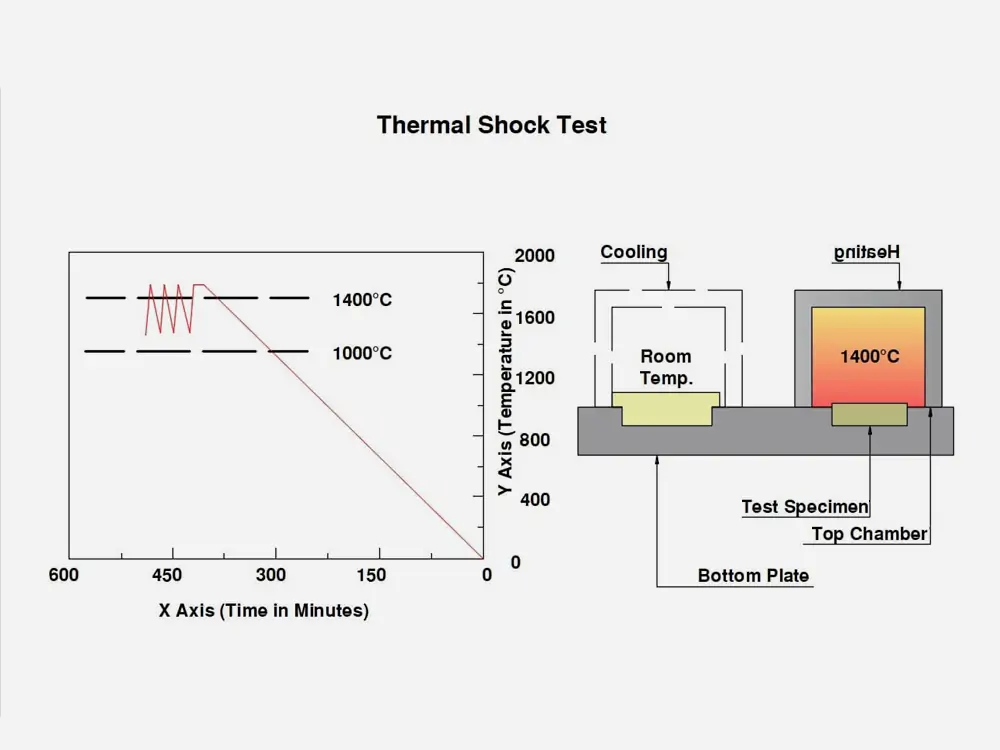

Process of Conducting Thermal Shock Testing

- The process of performing shock test involves placing a sample in chamber. This alternates between high and low temperature.

- The sample gets exposure to high temperature for some time. Then, it is undergoing to the transfer to a low-temperature environment.

- The rapid shift from the extreme heat to cold conditions of stress leads to other issues. This includes vulnerabilities and weaknesses.

- The number of cycles and temperature differentials vary from each other. This depends on the various testing requirements and standards.

- In the test, various parameters undergo monitoring. This includes hot and cold temperature, rate of change, and time for exposure.

- The different parameters help in ensuring the product ability. It also produce reliable results in the real-world conditions.

- Additionally, various equipment and data acquisition systems are useful. They help to analyze and record the performance of the material under test.

- This data is useful for the manufacturers. This helps to assess the ability of the material that survives thermal shocks. It helps to make informed decisions about the its suitability for specific applications.

Understanding Thermal Cycling Tests

As thermal shock tests are beneficial for sudden temperatures changes. Thermal cycling test examine the product performance that subjects to heating and cooling cycles. This is particularly useful when evaluating the long-term durability and stability of materials.

What is the Thermal Cycling Test?

In this test, the sample exposes to temperature variations in an extended time. This test involves temperature transitions. This aims to stimulate gradual temperature changes to the material in real-world applications. This process helps manufacturers to assess how materials withstand thermal stress. There are various factors such as expansion, contraction, and resistance.

Purpose of Thermal Cycling Test

This test is useful in industries where long-term material performance is critical. In electronics, thermal cycling test helps to check the reliability of integrated circuits. There are components like transistors that undergo temperature changes during the normal operation.

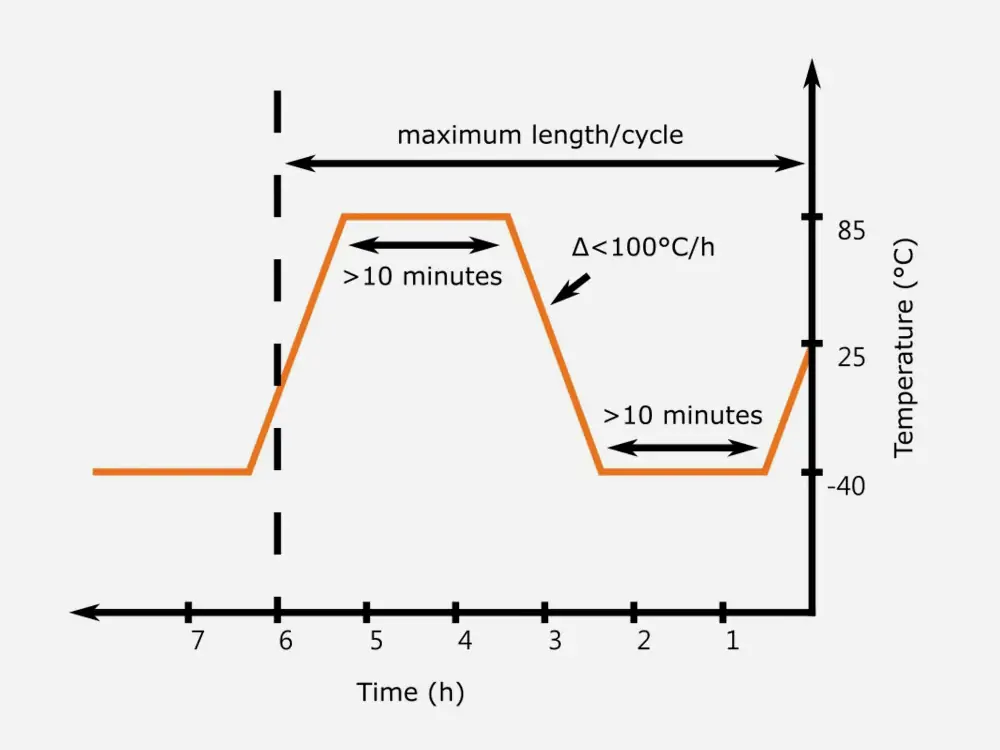

Process of Conducting Thermal Cycling Test

- The thermal cycling test involves sample exposure to heating and cooling cycles.

- Each cycle consists of specific temperature ranges and dwell times.

- This repeating process helps engineers and researchers to check 2 things. One is the reliability and other is durability of the material. Certain conditions are in consideration that mimic its anticipated usage.

- The number of cycles, dwell times, and temperature ranges vary from each other. This is due to the industry standards or specific requirements of the product test.

Key Differences Between Thermal Shock Testing vs. Thermal Cycling Tests

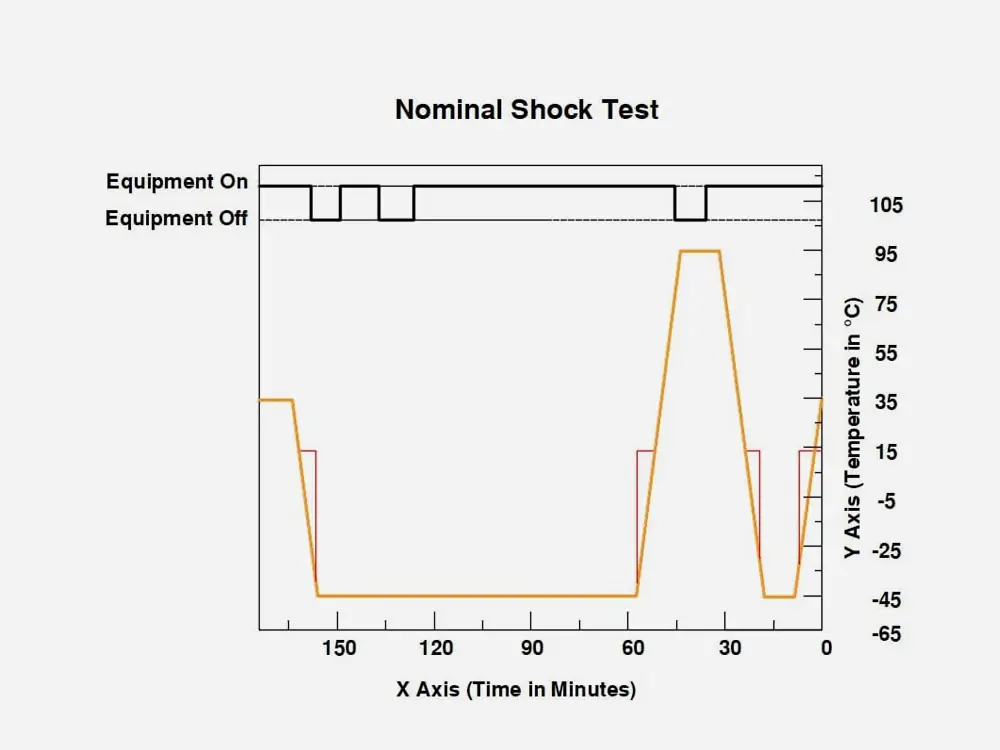

Both the thermal shock testing and thermal cycling tests check the temperature effect. This testing is beneficial for materials with several key differences.

Differences in Test Procedures

The key difference in thermal cycling and thermal shock test lies in test process.

- Thermal shock tests subject to rapid changes of temperature. This happens in less time even at extreme temperature conditions.

- So, thermal cycling tests involve gradual changes of temperature. This happens in more time at each temperature extreme.

These contrasting procedures are useful for the tests to work in real-time scenarios. Also, this helps to assess the specific properties of the material or products.

Variations in Test Purposes

- Thermal shock testing focuses on material’s resistance due to the temperature changes. These tests are helpful to identify the material’s ability. This undergoes extreme temperature differentials without any damage or failure.

- Thermal cycling test assess the material to withstand thermal expansion and contraction. This test is carried out for a extended time. This also provides insights into the durability of the material for long time. It also checks the stability in various applications with cyclic thermal stress.

Applications: Thermal Shock vs. Thermal Cycling Tests

Thermal Shock Test

- As this test works well for applications, it helps to identify the weaknesses. These flaws in material are due to sudden temperature changes.

- They are useful for testing in automotive, aerospace and electronics industries. Because during this test, many abrupt variations in temperature take place.

Thermal Cycling Testing

- Whereas, in thermal cycling tests assess the reliability for the long-term. This works good for various products and materials in applications.

- They work great for cyclic temperature changes. This includes renewable energy systems, telecommunication infrastructure, and industrial equipment.

Choosing the Right Test for Your Needs

When you choose a test whether it is cycling test or shock test, always consider the product nature. Also, it is important to keep the conditions in mind under exposure in its lifespan. If your product is prone to temperature changes, shock tests are more suitable. But, if product undergoes cyclic variations of temperature, cycling tests give relevant data.

Pros and Cons of Thermal Shock Test

Pros

- Efficient way to evaluate how a product responds to sudden temperature changes.

- Reveal potential weak points in a material or product’s design or composition.

- It is a cost-effective method, making it a preferred choice for industries

Cons

- It has a limited application range as all materials or products are not suitable for shock test.

- It can have an environmental impact if the thermal shock testing is conducted on a large scale.

Pros and Cons of Thermal Cycling Testing

Pros

- This test mimics real-world conditions, as it involves gradual temperature changes.

- It assesses the product’s performance under both high and low-temperature extremes.

- This shock test determines the product’s long-term durability and resistance to fatigue

Cons

- Cycling test is a time-consuming method

- This thermal cycling test is expensive compared to other testing methods.

As we drew knowledge towards the experts, this testing helps pick the tests for materials. These testing methods are beneficial for the companies. So, they can assess their material or products and make their design better. It also helps the industries to keep their customers happy and satisfied. Whether you test car parts or electronic devices, these tests are suitable to use. Both are indispensable tools in the arsenal of material scientists, contributing to the development of products that stand the test of time. Both thermal shock test and thermal cycling test are important to make use of technology.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]