In electroplating, durability and how materials perform are of significant importance. It is of no use to ignore the use of UV testing chambers in this industry. The UV chambers are super-powered sun lamps. These lamps help to check how the electroplated finish works in real-time conditions. It is essential to check for the manufacturers. Because it helps them to make sure that products last for a long time. No matter if they are outside in the sun or inside under lights. This includes improved corrosion resistance, wear resistance, conductivity, and aesthetics. But, the long-term performance of the electroplated finish is critical.

In this article, let’s go into the details of UV aging test chambers. And, how important these chambers are in the electroplating industry.

How UV Aging Test Chambers Simulate Real-World Conditions

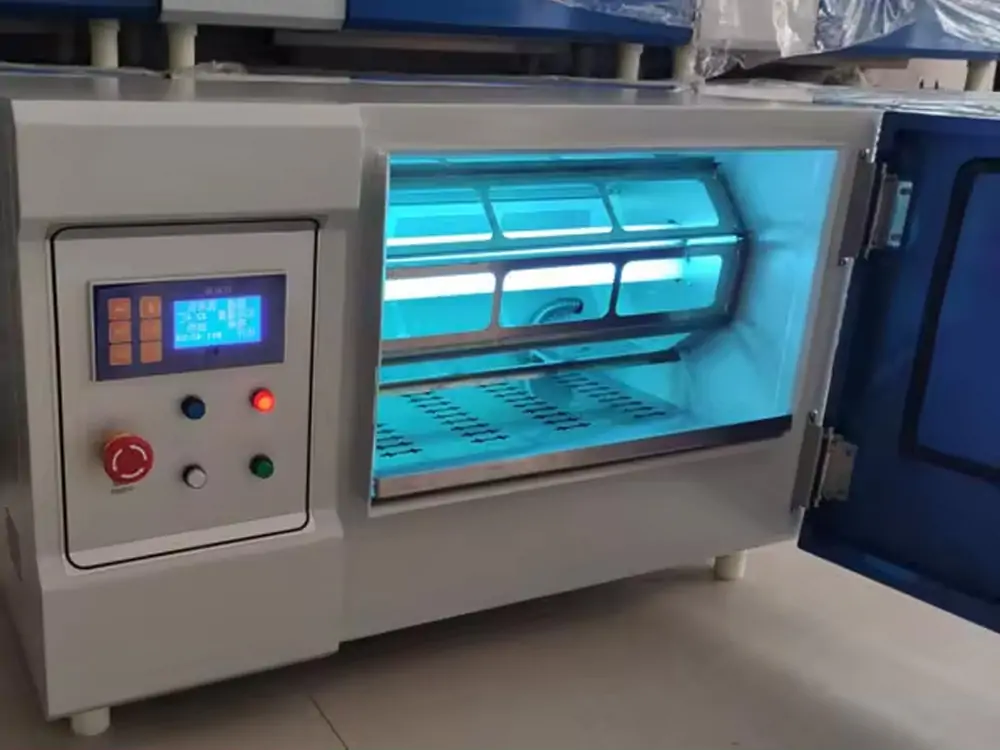

UV aging test chambers replicate the effects of exposure to sunlight on materials. These chambers use UV radiation, humidity, and temperature. This helps in testing using controlled levels of these factors. These controlled levels increase the degradation process. Also, it helps predict long-term performance. This is helpful in electroplated finishes. The process requires a compressed timeframe.

The key features of a UV aging test chamber:

- UV Light Source: These chambers emit calibrated UV radiation. This mimics the intensity and wavelength distribution of natural sunlight. For this purpose, different UV lamps are essential to use. Their use depends on the specific application and desired test conditions.

- Temperature Control: The temperature is easy to maintain in the chamber. This happens in various environmental conditions. The conditions become humid and hot climates. And, sometimes, it becomes cold in a dry environment.

- Humidity Control: The chamber can control humidity levels. This is important to simulate different environmental factors that can influence UV degradation.

- Monitoring and Data Acquisition: Modern chambers have sensors and data logging systems. This monitors temperature, humidity, and UV irradiance in testing. This data is crucial for analyzing the degradation process and quantifying the results.

UV Degradation and its Impact on Electroplated Finishes

Electroplated finishes undergo various environmental factors throughout their lifespan. The significant thread is UV radiation. It is a major component of sunlight. The UV exposure causes degradation of the electroplated over time.

The result is:

- Fading: The color and luster of the finish can diminish.

- Chalking: The surface may develop a powdery white residue.

- Cracking and Peeling: The electroplated layer loses adhesion and breaks down.

- Loss of functionality: The protective properties of the finish may deteriorate.

Benefits of Using UV Aging Test Chambers in Electroplating

The benefits of using UV test chambers in electroplating are:

1. Improved Quality Assurance

When electroplated samples undergo UV exposure, it identifies weaknesses in the plating process. Also, it helps to identify issues in material selection in early development. It is then easy to make adjustments before massive production. It ensures a durable and long-lasting final product.

2. Reduced Development Time

The evaluation of the longevity of electroplating finishes was longer through traditional methods. It involves a long time for outdoor exposure. In contrast, UV aging chambers provide a faster and more controlled way. It helps to assess the product performance. It leads to a quicker time-to-market.

3. Cost Savings

In the early phases, it was costly to identify and rectify issues. UV aging test chambers have reduced this. These chambers ensure the durability of the electroplated finish. The manufacturers can decrease warranty claims and associated costs.

4. Optimized Material Selection

UV aging tests help to compare the performance of different plating materials. It also helps to test the finishing processes under controlled conditions. This helps manufacturers to select the most appropriate materials for their specific application.

Applications of UV Aging Test Chambers in the Electroplating Industry

Electroplating plays a vital role in countless industries. It enhances the properties of various materials. Also, it ensures that the long-term performance of the electroplated finish is crucial.

Evaluating Finish Durability for Different Applications

This enables manufacturers to assess the durability of electroplated finishes across various applications. Car parts undergo intense UV radiation and high temperatures. This mimics harsh sunlight exposure. The building materials undergo test-simulating conditions. It evaluates the ability to withstand prolonged sun without color or structural degradation.

Electronic devices undergo exposure to controlled UV levels. This predicts how the finish will hold up under typical indoor lighting.

Optimizing Plating Processes and Material Selection

UV aging chambers refine processes. It makes it easy to select suitable materials. Manufacturers can test samples with various plating solutions. The testing is easy to conduct under identical UV exposure. Also, it helps to provide solutions for the most durable and UV-resistant finish.

Also, it helps to identify the effectiveness of pre and post-treatment methods. This enhances the UV resistance. These chambers investigate the effect of plating thickness on UV resistance. It becomes easy to determine the optimal thickness for durability and functionality.

Identifying Potential Failure Modes and Early Warning Signs

These chambers check potential weaknesses in the electroplating process. It is essential to check this step before mass production begins. Also, it is necessary to check the early signs of fading, cracking, or peeling. It allows for adjustments to the plating process or material selection.

UV aging tests reveal potential issues. These issues are between the base material and the electroplated layer. This helps manufacturers address any weaknesses in the plating process. Because these issues might lead to premature finish detachment.

Final Thoughts

In conclusion, the UV aging test chamber stands as an indispensable asset. This helps with quality assurance within the electroplating industry. It serves as the cornerstone to ensure durability and reliability. Also, it helps with the performance of coating and materials. UV aging test chambers help in quality control procedures. So, electroplaters gain a significant advantage.

These chambers provide a controlled and accelerated environment. This helps to predict the real-world performance. Also, it leads to various benefits in the industry. The UV aging test chambers are more than a tool. It is a cornerstone of quality assurance. Plus, it is a testament to quality commitment in the electroplating industry. The impact goes beyond the laboratory testing. It shapes the future of manufacturing. It ensures the continuous success of coating in an ever-changing world.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]