What is HAST testing of chips?

HAST testing is a fast stress test. It assesses chip reliability by simulating high heat and humidity. This speeds up aging and failure.

Why should chips undergo HAST testing?

Test the chip’s stability in high heat and humidity. Ensure it can work for a long time in a harsh environment.

To detect issues from high heat and humidity, such as:

Solder rupture,

Broken wires from expansion, and

Corroded connections.

Test the chip’s reliability. It must give accurate performance data for manufacturers and customers.

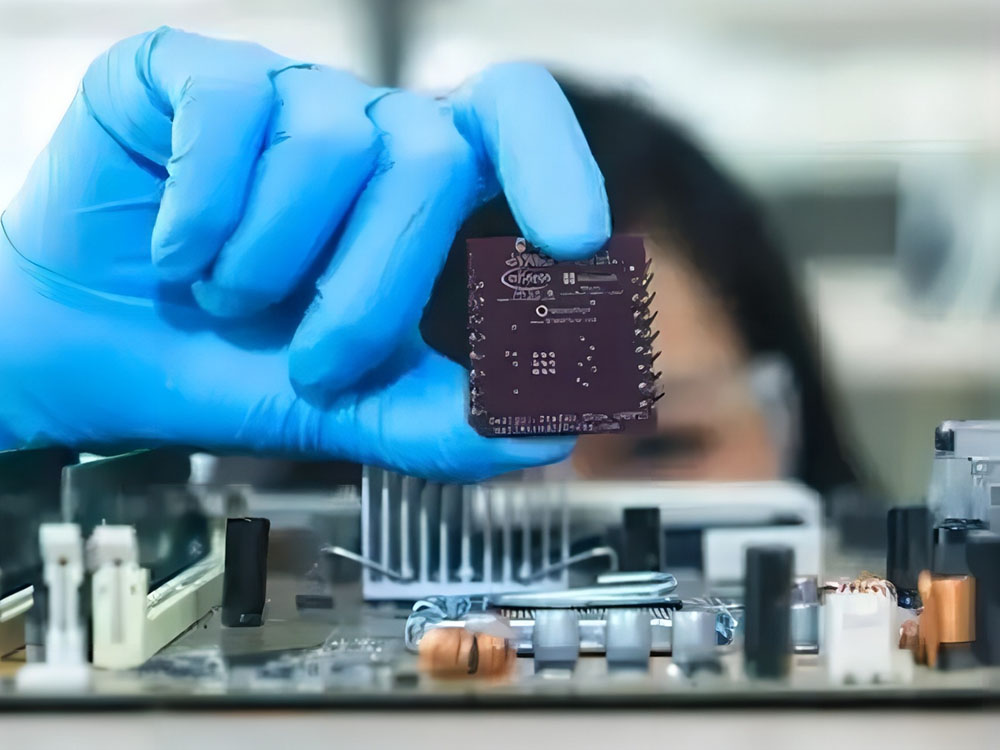

What is the role of the test holder in HAST testing?

In HAST testing, the test holder is the key component that connects the chip to the test equipment. It sends electrical signals to the chip and returns the test results. The test bench provides a stable interface. It ensures accurate communication between the chip and the test equipment. It also ensures the test data’s accuracy and consistency.

First, high temperature and high humidity test test stands. They must withstand them. In HAST testing, the temperature is usually between 100°C and 150°C, and the humidity is as high as 85% to 95%. Thus, test stands must endure high heat and humidity to be reliable. The test holder’s materials and design must account for these factors. They must ensure it does not fail or affect the test results.

Secondly, the test holder must also provide good electrical performance. It must ensure good signal transmission and low resistance connections. This will enable accurate communication between the chip and the test equipment. During design and manufacturing, it is essential to test the test holder’s electrical traits. These include contact resistance, insertion loss, and signal amplitude.

The test holder’s design must match the chip’s package and test equipment. Different types of chips have different package forms, such as die, QFN, BGA and so on. The test bench must design to match the chip’s different packages.

Why HAST test?

Routine assessment of product reliability

Accelerated assessment of product reliability through temperature, humidity, bias and other stresses.

It dramatically reduces product development cycles compared to traditional temperature and humidity testing.

HAST test temperature is usually above 105 ℃. High humidity increases pressure, which speeds up moisture absorption. It quickly saturates the device. The HAST test, commonly run for 96 hours, is a faster alternative to the 1000-hour THB test.

High heat and humidity can cause water vapor to adsorb, absorb, and diffuse in the test samples. The material can expand as it absorbs humidity. This can reduce strength and mechanical properties, and harm performance. The water vapor can also lower the insulating materials’ electrical properties.

Effectively improve the company’s test capacity and efficiency

The shorter test time lets us test more products for temperature and humidity. U.S. data shows humidity causes 19% of device failures. The main failure modes caused by humidity: corrosion, particle migration, diffusion, hydrolysis.

Accelerated aging test (HAST) what test categories?

High temperature step stress test

Vibration step stress test

Comprehensive stress test

Low temperature step stress test

Rapid thermal cycling test

Working stress test

In what fields can we apply HAST?

HAST Weathering Test is widely used for accelerated weathering life testing of products. For example, EVA, connectors, and photovoltaic modules. Also, there are polymer materials, circuit boards, semiconductors, magnetic materials, and integrated circuits. To reduce the time for life testing of a system or product and accelerate the test process. Accelerated life testing requires additional operational and environmental stress. Users rely on the test to check the wear and life of mechanical and electronic parts. It also finds the causes of increased failure rates.

What are highly accelerated stress test chambers?

HAST is a test device. It simulates aging in products at high temperature and humidity. HAST stands for Highly Accelerated Stress Test. The tester uses high temperature and high humidity to speed up the aging of products. This helps find problems that may occur in long-term use. It also guides product design and improvement. We usually use the HAST tester for product testing. It’s used in electronics, optoelectronics, and other industries. These include the chemical, automotive, and aerospace fields.

What is a highly accelerated stress test?

The HAST test is a highly accelerated reliability test for electronic components. It’s based on temperature and humidity. Its full name is Highly Accelerated Temperature and Humidity Stress Test. The highly accelerated aging test is now a standard, high-temp, high-humidity test. Manufacturers use it in semiconductors, PCBs, solar panels, displays, and other products. The aging test is now the standard. It is a fast, effective alternative to high temperature and humidity tests (e.g., 85C/85%RH-1000 hours).

How to install a highly accelerated pressure tester?

There are many steps to install highly accelerated pressure test chambers. It’s vital to ensure safety and effectiveness.

Determine the ultimate stress level. First, find it in the test specimen. This is the test’s basis. If the sample does not fail at this ultimate stress, the test can stop to avoid damage.

Install the sample: The test product is in the highly accelerated life test chamber. Also, make the necessary electrical, signal I/O, and monitoring connections. Use sensors (e.g. temperature sensors, accelerometers, etc.) to monitor the stress levels applied to the test product. The various connections should withstand the stresses of the test.

Initialisation test: Before formal testing, the subject product must work. So, it is functionally tested. We also need to test the monitoring equipment. It must work properly. Also, check the integrity of any cables connected to the product under test. They must work properly under high stress, like high air flow.

Increasing the test stress: Gradually increase the stress to the specified stress level. If we monitor the test product, we can increase the stress level. If no one monitors the product, the stress level gradually increases. This is to stabilize the product at each stress level before testing for failures.

Data analysis and report writing: After testing, we collect and analyze the data. This checks for any changes in performance under extreme conditions. A detailed report, based on the tests, is prepared. It summarises the product’s performance and possible issues.

The installation and testing must follow the operating procedures. This is to ensure safety and achieve the test’s purpose. Also, different test chambers (e.g., PCT High Temp and HAST) have different methods and precautions. So, read the relevant manuals before use.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]