In electronics, processing is complex and uses many materials. They can have both processing and component defects. These defects are obvious or potential. Obvious defects make the product not work, like short or broken circuits.

Products with possible defects may be used temporarily. But, the defects will be quickly exposed in use. Then, the product will not work. Normal inspection cannot find potential defects. But, we reject them by using aging methods.

If aging method doesn’t work, defects it misses will show up. They will cause early failures or malfunctions during the product’s use. This will lead to more returns and higher maintenance costs.

1、Concept

A certain temperature and long exposure to environmental stress cause aging. Environmental stress screening includes many stresses. These include temperature cycling and random vibration, not just high temperatures. These stresses speed up many reactions in the components. They do so by acting together on the reactions. This early revelation of potential defects allows us to eliminate early failures. To achieve the purpose of eliminating early failure products. Aging is a kind of environmental stress screening.

2、Role

①These defects may exist in manufacturing. They include surface staining. They also have poor lead welding and channel leakage. There are wafer cracks, oxide layer defects, and local hot spots. They have a better screening effect.

②For defect-free components, aging also makes its electrical parameters more stable.

3、Aging test items

The main aging test items are:

3.1 Light aging test:

Light aging is the main outdoor use of materials subjected to aging damage, for indoor use of materials, will also be subjected to a certain degree of light aging. Aging the main three lamps with light has its advantages. The carbon arc lamp was the first to use. Many Japanese and fiber material standards use carbon arc lamps. But, they are expensive and unreliable. You need to replace them after 90 hours. So, xenon arc and ultraviolet lamps have replaced them. Xenon lamps have a big advantage in mimicking natural light. They are cheap, making them good for most products.

UV lamps produce light below 400nm. They can speed up simulating natural light in the ultraviolet. This light destroys materials. They are faster than xenon lamps. They are more stable. But they tend to produce non-natural light that damages things (especially UVB lamps).

The main applications are outdoor and indoor use. They are for rubber and plastic, paint, and ink products. And they are also for communications, electrical equipment shells, and other equipment. They are for automotive and motorbike parts.

3.2 Thermal aging

Main reference standards: ASTM D3045, JIS K 6257, and so on.

The heat aging box has a procedure function. You can set the temperature change through the procedure. It suits the needs of heat aging various products.

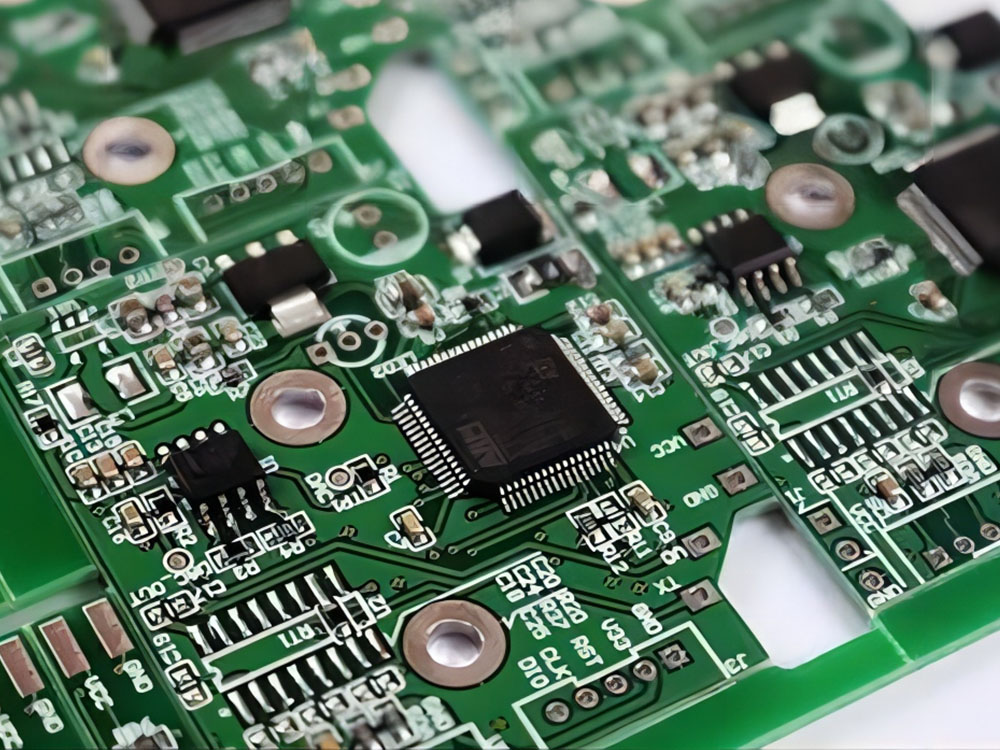

This test is for heat-resistant aging of various products. It applies to PCB boards and insulating rubber in electrical appliances. It’s also for long-life products. For example, the jacket material in cable-stayed bridges used for over 20 years. The test looks at how time changes the material and product performance. It also checks the reliability of the product.

3.3 Damp heat aging

The main reference standards: are general standards such as GB/T 15905, and GB/T 2573.

In addition, it can be set for different product standards. These include the humidity and temperature curves of enterprise standards. It is good for many complex thermal aging tests. When using the product, both temperature and humidity can easily affect you. Some materials, like PET and PBT, are sensitive to water. The test checks if they can use long-term in humidity.

3.4 Salt spray aging

Main reference standards: ASTM D117, JISZ2371, and other standards.

Neutral salt spray, acid salt spray, copper ion accelerated salt spray test. It is mainly used to simulate the salt in the air. The salt has a corrosive effect on coatings, plating, and other protective procedures. This effect is due to the salt dissolved in water vapor. It is especially a problem in coastal areas and inland salt lakes where the air salt is high. The high salt makes products very easy to corrode by salt spray.

This rule mainly applies to coatings. They include building exterior coatings, marine coatings, container coatings, and more. It also applies to plating.

3.5 Ozone aging

Main reference standards: HG/T 2869, JIS K 6259, ASTM D 1149.

It mainly examines how rubber resists ozone. Rubber has many double bonds, which ozone easily attacks. This is particularly true when using rubber dynamically or stretching it. It also examines how new elastomers, such as TPU and EPDM, resist ozone.

3.6 High and low-temperature cycle

The main reference standards are JG/T 25 for architectural coatings. They cover the method for testing freeze-thaw cycle resistance. Other standards can also cover these tests. It is mainly used for testing architectural coatings. It is also used for special environmental equipment.

4、Electronic components aging test precautions

To achieve satisfactory results in aging, you should note the following points:

① The aging equipment should have good measures to prevent self-excited oscillation.

When applying a voltage to the device, increase it slowly from zero. Reduce it slowly when de-voltage. If not, the sudden voltage change may damage the device. After aging, measure promptly within the time in the standards. Otherwise, certain out-of-spec parameters will return to their original values.

③ Measure its thermal resistance carefully. This ensures that the highest junction temperature can age it.

For integrated circuits, their operating voltage and current face tight restrictions. So, their junction temperature rises very little. It does not get hot enough for aging. The rise does not raise the air temperature. So, static power aging at room temperature applies to only some types of integrated circuits. These include linear and digital circuits.

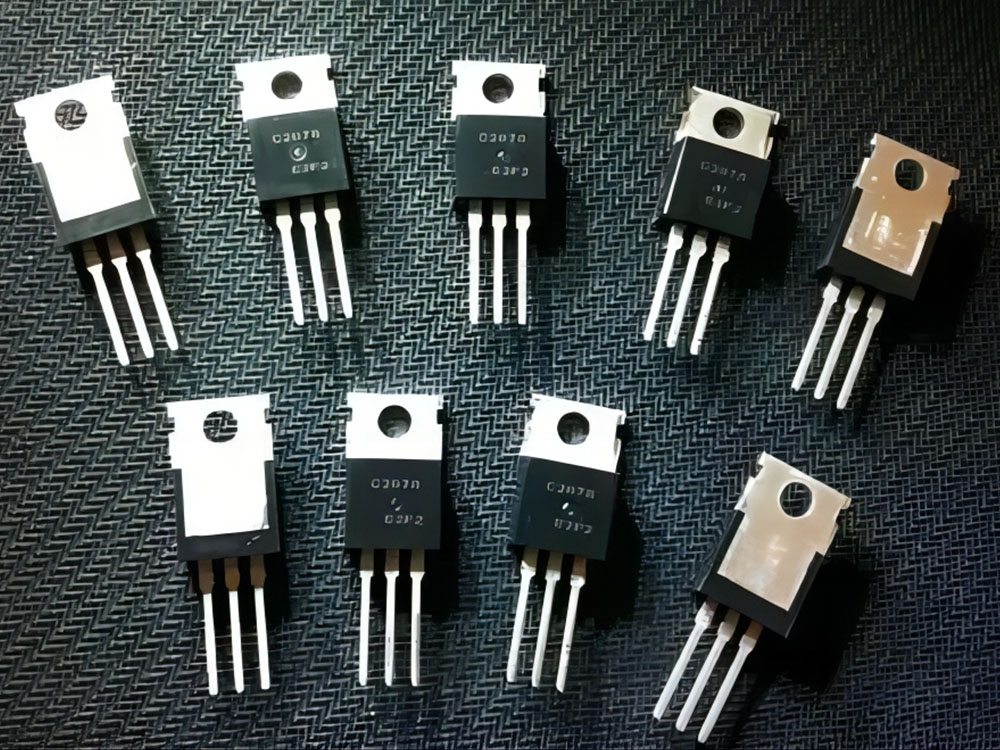

5、 Semiconductor devices commonly used in aging screening methods

5.1 Room temperature static power aging

Room temperature static power aging is to make the device at room temperature aging. The semiconductor PN junction is in a positive bias state. The thermal stress required for device aging comes from the power the device uses. The device is aging due to the combined effects of electricity and heat. This speeds up its internal physical and chemical reactions, revealing potential defects early. Then, we remove the defective device. This aging method does not need high-temperature equipment. The operation is also simple. So, it is commonly used. In the safe range, a small increase in aging power raises the device temperature. This can improve aging and shorten the aging time.

To get the aging to work well, pay attention to these points:

① Aging equipment should be a good measure to prevent self-excited oscillation.

② When you apply a voltage to the device, slowly increase the voltage from zero. Slowly reduce it as well. If not, the sudden voltage change may damage the device. After aging, measure on time. It must be within the time in the standard. Otherwise, some parameters will return to their original values if they go out of spec as they age.

③ To ensure the transistor can age at high junction temperature, measure its thermal resistance well.

For integrated circuits, their voltage and current have tight limits. So, their junction temperature rise is very small. It does not raise the ambient temperature. This makes it hard to reach the temperature needed for aging. So, static power aging at room temperature only affects some circuits. These circuits are linear and digital.

5.2 High-temperature static power aging

The aging method uses high temperatures. The test circuit is the same as for the room temperature method. The difference is that the former is at a higher temperature. As the device is at a higher ambient temperature for aging. This can make the circuit’s junction very hot. So, in general, high-temperature aging harms integrated circuits more than room-temperature aging.

Some military electronic component standards say the chip must endure high-temperature power aging. The conditions are specific. Aging happens under the product standard’s rated voltage. This includes supply voltage, load, signal, and line. You can determine aging conditions as needed, which are 125 ± 3 ℃ for 168 hours. We monitor the aging process at least once every 8 hours.

High-temperature reverse bias aging

During aging, the device’s PN junction faces high heat and reverse bias. Almost no current, and thus almost no power, passes through the device. This aging method is great at rejecting early failure devices. They have surface defects. It is widely used to age semiconductor devices for some reverse applications.

High-Temperature Dynamic Aging

High-temperature dynamic aging is mainly used for digital devices. A pulse signal drives the input of the aging device. This keeps the device constantly flipping back and forth. This aging method is very close to the actual use of the device.

High-temperature dynamic aging has two basic test circuits. They are series switching and parallel switching circuits.

A series switching test circuit is also known as the ‘ring counter’ circuit. This device under test has all its outputs and inputs connected in a series. They form a ring counting circuit. The latter level gets the output of the former level. So, the latter level is the load of the former level. It does not need extra excitation signals or loads. The equipment is simple and easy to use. The downside is that one test device failure will stop the whole ring system. Until replaced with a new test circuit or short the problematic device is, the test is back to normal.

The device under test defines the test circuit. It connects in parallel with the power supply. This setup allows driving each tested device individually. The switching voltage drives them. Each device can connect its output to a maximum load. This setup overcomes the problems of series switching aging.

The test is at the highest-rated operating temperature and voltage. It lasts 168 to 240 h. For example, civilian equipment is typically a few hours. Military high-reliability equipment may choose 100 ~ 168 hours. Aerospace-grade equipment can choose a cycle time of 240 hours or even longer.

6、The aging of components

These tests age resistive elements. They apply the power and temperature required by the specification. The operator should note the need for heat dissipation. They should pay particular attention to this after ageing.

② Capacitor aging test generally uses high-temperature voltage aging. This is the capacitor’s highest rated operating temperature. It is under the rated voltage for 96 ~ 100 hours. It is to weed out defective products caused by breakdown and short-circuit in the medium. Tiny holes, defects, and conductive particles in the film cause the capacitors to fail. For example. This happens during high-temperature voltage aging. The defects cause short circuits. In flawed liquid tantalum capacitors, high-temperature aging causes a large short circuit. This current heats the product suddenly. The electrolyte and solder quickly vaporize. This makes the pressure rise enough to destroy the product.

For defect-free capacitors, high-temperature aging removes internal stresses. It also improves the capacitor’s dielectric properties and stability. High-temperature voltage aging can make the dielectric defective. It affects metallized paper dielectric (or plastic foil film) capacitors. This aging can cause them to ‘self-heal’ to restore their performance.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]