A constant temperature and humidity test chamber is widely used in many industries. It simulates temperature and humidity changes in different environments. It tests the physical properties of various materials, including:

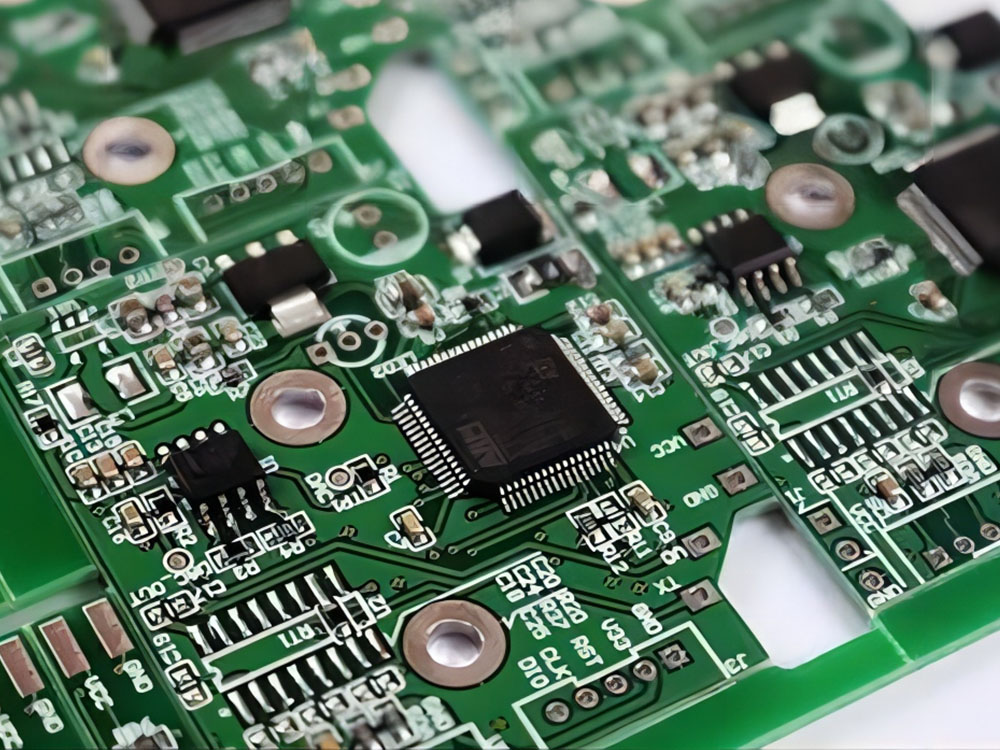

electronic and electrical components

automation parts

communication equipment

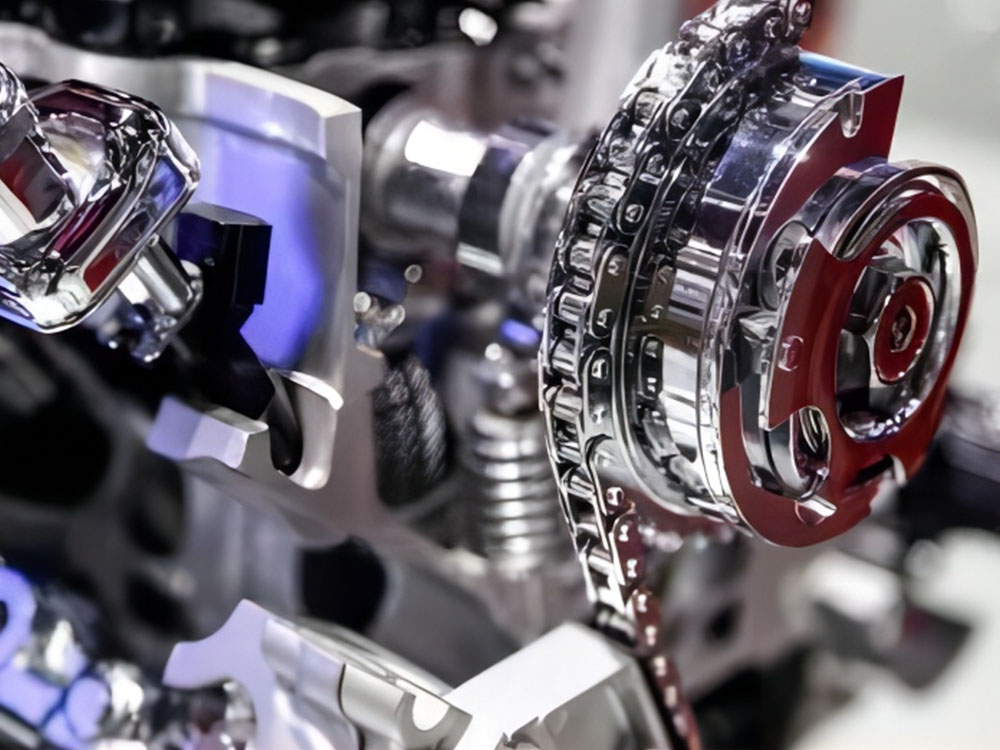

automotive parts

metals

chemicals

plastics

This equipment is vital in the defence, aerospace, and military sectors. It is also critical for testing BGAs, PCB spanners, and chips. Also, it tests semiconductors, ceramics, magnetic materials, and polymers. It tests materials’ resistance to extreme temperatures and damage from temperature changes. This ensures product quality.

Constant temperature and humidity test chambers can test electronic components. Their uses include: performance testing, troubleshooting, durability testing, stress screening, and environmental adaptability. These chambers are key for testing products in many fields. They range from precision circuits to heavy-duty components. They help manufacturers improve quality and meet performance standards. Jinjian Laboratory launched a ‘double 85 temperature and humidity test.’ It helps customers assess their products’ heat and humidity resistance. We also offer a test analysis and improvement program. This supports product R&D and quality control. It aims to boost product competitiveness and user satisfaction.

1. High temperature storage

Most electronic components fail due to changes in their body and surface. These are physical and chemical changes. These changes are closely related to temperature. After the temperature rises, the chemical reaction speeds up. This accelerates the failure process. Expose defective components in time to eliminate them.

High-temperature screening is widely used in semiconductor devices. It removes failure mechanisms like surface contamination, poor bonding, and oxide layer defects. It is generally stored at the highest junction temperature for 24~168 hours. Screening at high temperatures is simple and cheap. It can test many components. After high-temperature storage, it can stabilize component performance and reduce drift in use.

2. Electricity test

The screening process must reveal defects in electronic components and their surfaces. Using integrated thermoelectric stress can do this. It’s a key step to ensure the components’ reliability. Screening of electronic components is usually done at rated power. It lasts from a few hours to 168 hours.

For some products, especially integrated circuits, be careful when changing the test conditions. It may harm their performance. In these cases, we can achieve high stress test conditions. We do this by raising the operating temperature. This increases the junction temperature. Power refining tests need costly, specialized high and low temp test chambers. The screening time should be short to avoid wasting resources.

In civil products, screening takes a few hours to ensure reliability. For military use or high-reliability products, the screening time may be 100 to 168 hours. For aerospace-grade components, the screening cycle may be longer. It may take 240 hours or more to meet performance requirements in extreme conditions. This careful screening process ensures the reliability of electronic components in various environments. It improves the quality and performance of the final product.

3. Temperature cycling

In use, electronic products will face many temperature challenges. Thermal expansion and contraction can cause failures in poorly matched parts. They are prone to this under temperature changes. Temperature cycling testing is a screening method. It uses the stresses from extreme high and low temperatures. This tests for components with thermal performance issues. This type of testing typically consists of 5 to 10 cycles over a temperature range of -55°C to 125°C.

Power refinement testing requires costly, specialized test equipment. So, we must keep the screening process to a reasonable length. For civilian electronics, the screening time is usually short. It’s only a few hours, to keep costs down. For military or high-reliability products, the screening time may be 100 to 168 hours. Aerospace-grade components may need a longer, 240-hour screening cycle. This is due to their high reliability requirements.

This careful testing can greatly improve the reliability of electronics in extreme temperatures. It will ensure their reliability in various environments.

4. The need to screen components)

The reliability of electronic components depends on the product’s design. Not all products are reliable after manufacturing. Human factors and variable conditions can affect them. Each batch of finished products has some defective items. They may fail early under certain stress conditions. The average life of an early failure component is much shorter than that of a normal product.

The reliability of electronic equipment depends on its components. If the whole equipment has the early-failure parts, its failure rate will rise greatly. Its reliability will not meet the requirements, and repairs will be costly. So, for both military and civilian products, screening is key to ensuring reliability. To test electronic components, use a constant temperature and humidity test chamber.

Constant temperature and humidity test machine use precautions are?

1. The refrigeration system is the core of the tester. It is a constant temperature and humidity tester.

Please check all steel tubes for leakage at least once a year. All joints and welded joints, if there is oil leakage, please deal with it in time.

2. Frequently check the dry bulb and wet cloth.

Only control the temperature and humidity if the test cloth’s surface becomes dirty or hard, or if it exceeds 85℃. After checking, if it does not absorb water, replace it. It relates to the accuracy of moisture measurement. The test cloth is usually replaced every three months. When replacing, we should wipe the temperature measuring body with a clean cloth. When replacing the new test cloth, please wash your hands and then clean the sink. Clean.

3. When you pick up the product after completing the testing time, remember to turn it off.

Staff must wear dry, electrical and moisture resistant gloves before picking up and placing the product.

4. The chamber’s body and floor must always be clean.

To avoid accidents and poor performance from dust in the unit.

How to measure the constant temperature and humidity tester?

1. Turn on the power switch.

2. Check whether the fan in the box is working properly, whether the wind speed is normal, whether there is abnormal sound.

3. Constant temperature and humidity setting, press the setup button, press once to enter the temperature setting, wait for the temperature number flashing, set the desired temperature value. Press the setup button twice to enter the humidity setting, wait for the temperature number to flash, and then set the desired humidity value.

4. Time setting, press the time button, press it once to enter the day setting, wait for the day number to flash, and set the desired day number. Press the time button twice to enter the clock setting, wait for the clock number to flash, then set the desired clock value. 5. Press the time button three times in succession to enter the minute setting, wait for the minute number to flash, then set the desired minute value.

5. Set the temperature online value, the maximum temperature value of this constant temperature and humidity box is 100℃.

6. Place the item to be tested on the shelf of the box.

7. Close the door.

8. Automatically heat and humidify to start the test.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]