There are many types of textiles, including clothing, bedding, and other ordinary textiles. Outdoor textiles are also a kind of textiles. Such as tents, umbrellas, sun umbrellas, exterior garments, industrial textiles and overlays. The materials of outdoor textiles include plant fibers, polyester, and coatings. Dyed or colored textiles fade or change color when exposed to heat, sunlight, and humidity. Besides, synthetic or natural polymers lose their chemical intensity. Thus, textiles need to be tested to determine their stability and durability.

Textiles are usually exposed to sunlight when in use. Light destroys the dyes on the product, producing fading and usually a whiter or darker color. Colorfastness to light is a textile fades degree when exposed to light during use or processing. Colorfastness to light is an important indicator of textile performance.

Precautions for textile color fastness to light test

Sampling

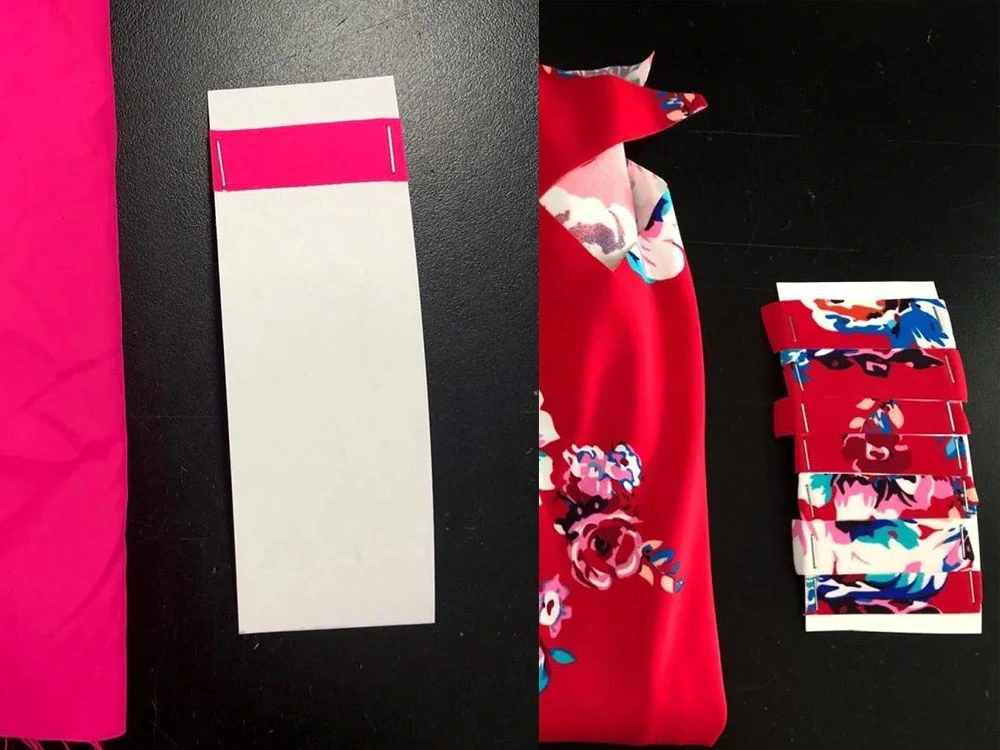

Colorfastness to light to take samples of all colors, at the same time to ensure that the light to all colors. The cover plate should be in close contact with the exposed part of the specimen and the blue wool label. But, the mask should not be excessively tight. Ensure that the size of the specimen to be tested is under the standard. The specimen and fleece should be of the same shape and size to avoid errors in grading due to differences in area. Some pile fabrics have uncertain pile directions, which may make evaluation difficult. In this case, the exposure area should be increased appropriately.

Specimen size according to the number of specimens and the shape and size of the specimen clip. If the specimen is a pure color textile, it is usually cut (45 x 10) mm in the direction of the warp threads of the textile. If the sample is printed or multi-color fabrics, it is necessary to take more than one specimen. The specimen is symmetrical to the left and right to ensure that each color is exposed to the sun.

Operation process

(1) Equipment

Ensure that the equipment meets the test conditions specified in the standard. Strictly follow the related operating program. Use a red cotton or blue wool sample to examine the unit for operation. The testing process should also ensure the continuity of the test.

(2) End point determination

In the textile testing methods, the most are through the wool to determine the endpoint. Besides, there are also some through the sample itself or the reference sample and so on. Thus, the operator is familiar with the endpoint determination rules of each method. The experimental process should be repeatedly viewed, not more or less light.

Rating

The current method of textile color fastness rating is based on visual inspection. This requires a certain level of technical rating personnel. Raters usually need to develop good eating habits. Raters should strictly follow the requirements of the standard. For complex samples, after one person rating, other people re-rating. This is to ensure the reliability of the test results. To cut the difference in gaze between raters, the difference in gaze needs to be compared regularly. Reduce the loss brought to the enterprise and the customer due to the difference in eyesight.

Colorfastness to light is a common item for fabric color fastness tests. To ensure objectivity and accuracy, the test must follow the relevant standards. This requires the testing personnel to fully grasp and understand the standards. At the same time pay attention to the details of the testing process.

Colorfastness to light test

Importance of color fastness to light test

If you want to export textiles, your goods need to follow global standards. Colorfastness to light is the most significant global criterion. A qualified color fastness to light test report must be issued before the products can be sold. The color fastness to light test can help to enhance the product’s capabilities. And improve product quality and core market competitiveness.

Principle of light color fastness testing

The light color fastness test imitates the fading of textiles under sunlight exposure. The color fastness to light of fabrics is judged accordingly.

Light color fastness testing methods and equipment

Generally, the test of color fastness to light is based on sunlight. But, to help the control, artificial light is used for the test. Thus, the color’s fastness to light is also divided into sunlight and artificial light. Direct exposure to sunlight is usually called color fastness to sunlight test. Artificial light is called the light color fastness test. The reason for the color change of fabrics by light is complicated. This is not just about the chemistry of the dye. This is also linked to the features of the dyed fabric, the light source, and other factors.

Colorfastness to light is also known as colorfastness to sunlight. It is not workable to place the specimen directly under the sun as described in the definition. That’s the reason it takes months or even years for textiles to fade under natural light. With today’s ever-changing products, this inefficient method of testing is not workable. To increase productivity, the aging process must be shortened and conclusions drawn quickly. This is where the sunlight fastness tester comes in. Simulating the natural light source, and accelerated exposure, got rapid test results.

Methods to improve the color fastness to light of textiles

① Selection of dyestuffs according to the nature of fibers and the use of textiles.

Cellulosic fiber fabrics should use dyes with good anti-oxidation properties. For protein fibers, dyestuffs with good anti-reduction properties should be used. Dyes containing weak oxidizing additives can also be selected. Other fibers shall be chosen according to the results of the discolored dyes.

② Select dyes according to the depth of color

The active dye’s light fastness on cellulose fibers is proportional to dye consistency. This means that the deeper the color, the greater the light resistance. The greater the consistency of the dye, the larger the extent to which the molecules are gathered. The smaller the surface of the dyestuff exposed to air, moisture, and light, the lower the chance of light oxidation.

However, the paler the color, the higher the degree of dispersion of the dye in the fiber. The chance of exposure to rays is greater and the color fastness to light is reduced. Therefore, when staining light-colored species, use dyes that have good light fastness resistance. Besides, fabrics have added finishes that decrease the product’s light fastness. Examples include emollient and wrinkle-resistant finishes. Thus, dyes that are insensitive to those sorting compounds are to be applied.

③ Select dyes of great light stability and consistency for color blocking.

Dyes with varying discoloring characteristics and even different photofading regimes. Occasionally, the existence of one dye will cause another to fade. For color blending, use dyes that are insensitive to one another’s light. It is even possible to improve the light stability of the dyes. It is particularly vital in dyeing deep colors like black.

Fading of any of the 3 original colors too fast can lead to fading of the fabric. The faded dye remnants also influence the photostability of other unfaded dyes. Proper management of the dying procedure, makes the dye and the fiber combine well. Try to avoid hydrolyzed dyes and unsolidified dyes remaining on the fiber. This is an essential method for getting great color fastness.

Summary

As the textile industry develops, people’s demands on textiles become more demanding. People’s requirements are no longer limited to covering the body and keeping warm. In addition to aesthetics, and comfort, textile environmental friendliness is also emphasized. Light fastness is one of the most important factors in textile environmental protection. As every piece of clothing cannot escape the fate of direct exposure to sunlight. The dramatic color fading caused by sunlight on textiles is of particular concern. Garments made from fabrics with poor color fastness to light can become discolored. This seriously affects the overall effect and service life of the garment. That’s why consumers are demanding more color fastness to light from clothing fabrics.