With the increasing population and urbanization, more and more resources are in use which is leading to the release of harmful emissions from certain materials into the air. This release of harmful chemicals affects living beings as well as the natural environment. We often use a VOC Emission Test Chamber to study the behavior and effect of these harmful contaminants or emissions. VOC includes a wide range of carbon chemicals that have high vapor pressure even at room temperature. These include phenol, styrene, naphthalene, and formaldehyde which evaporate easily in the air. All these VOCs are evaluated and determined by this VOC test chamber. Usually, the testing of the product is done to reduce the emissions of VOCs in the indoor environment.

How Does VOC Emission Test Chamber Works?

A VOC emission test chamber works in a controlled environment to analyze and measure the release of VOCs from certain products, systems, or materials. Following are the steps of how this test chamber operates:

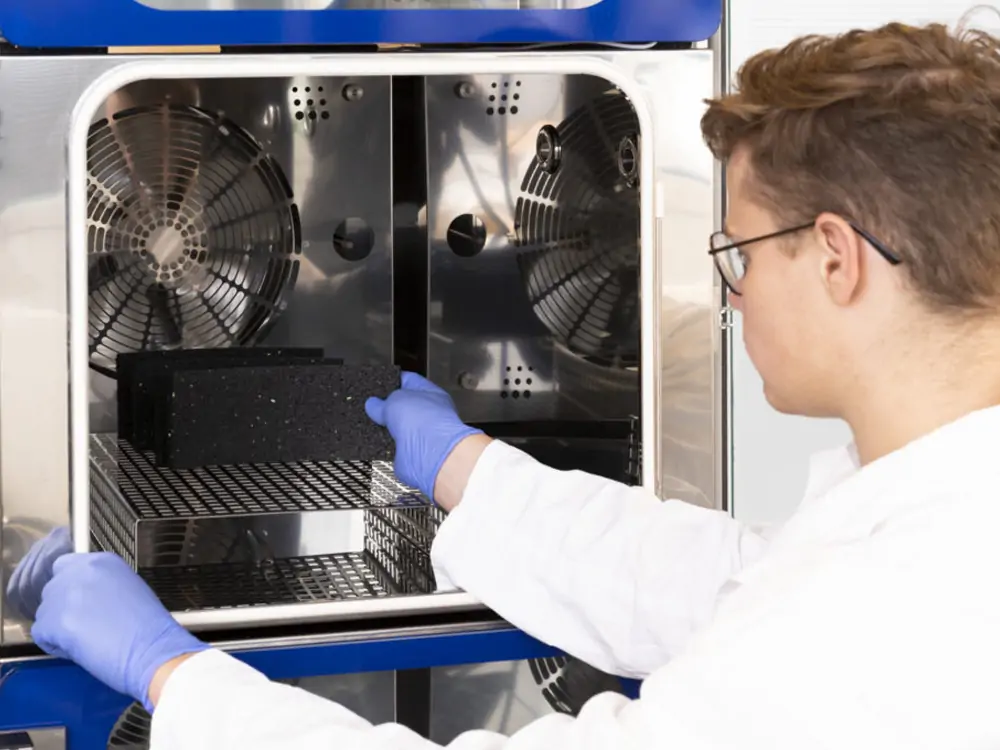

- Chamber Setup

In it, you prepare a chamber in an enclosed area or space with controlled temperature, airflow, and humidity. The chamber is made of certain materials that do not emit VOCs. These include glass or stainless steel. - Sample Preparation

In this step, you need to put the system or product that needs testing inside the test chamber. The samples include furniture, electronic devices, textiles, building materials, large assemblies, and vehicles. - Conditioning Phase Before Testing

Next comes the conditioning phase before the start of the testing. The sample undergoes a period that stabilizes the VOC emissions. This involves the exposure of the samples to specific humidity, temperature, or other environmental conditions for accurate results. - Emissions Measurement

Then comes the measurement of the emissions. When the samples are conditioned, the air inside the test chamber is sampled continuously and then analyzed to measure the VOC concentration. This is done using a mass spectrometer or gas chromatograph to determine VOCs in the air. - Sampling Time

Now, comes the duration of sampling. This depends on certain standards and requirements and ranges from a few hours to some days. This allows to collect maximum data for the assessment of VOCs.

Then, the collected data of the VOC emissions are analyzed further to detect how much VOC is present in the samples and what are the emission rates. This data is important for compliance, improving air quality, and for the development of products.

Lastly comes the reporting step in which testing is gathered in a report that provides all important details regarding the emission levels.

Different Sizes of VOC Emission Test Chamber

The size of the test chamber varies that depends on the applications and the requirements. These chambers accommodate different sizes of samples and are available in different sizes.

- Small-Size Chambers

These test chambers are useful for smaller material or product testing. This includes small electronic devices, furniture, textiles, and building materials. The dimensions of these chambers range from a few m3 to 10 m3.

- Medium-Size Chambers

These chambers are useful for performing testing of large products. These include appliances, construction components, and automobiles. The chamber volume range from 10-100 m3.

- Large-Size Chambers

These testing chambers are best for the testing of larger items. This includes aircraft, large structural components, and entire vehicles. Their volume exceeds 100 m3 while some of the chambers have several 1000’s m3.

Uses of VOC Test Chamber

There are different uses of VOC test chambers in various industries. Some of the key uses of this testing are:

- VOC testing is useful to meet the environmental standards and regulations set by the agencies.

- VOC Emission testing also helps in producing new materials that have low VOC emissions and move towards eco-friendly options.

- This is helpful for the assessment of indoor air quality in offices, homes, and schools. This helps to identify the sources of indoor air pollution.

- VOC emission testing plays an important role in the evaluation of health and safety concerns. This is done to ensure that the materials and products are safe for the workers and consumers.

- This testing is particularly important for EIA. It helps to identify areas that need improvements and work for a better living environment.

- VOC testing is important for quality assurance and quality control. By proper testing, companies ensure that their manufactured products meet the standards.

Applications of VOC Emission Test Chamber

There is a wide range of applications of VOC chambers for testing in various industries. Some of their applications include:

Building Materials:

This VOC testing is useful for materials like coatings, sealants, flooring, adhesives, paints, and insulation. This helps to comply with the standards and regulations, thus also helps for the assessment of air quality indoors. Furthermore, it also helps to develop eco-friendly and low-emission-releasing materials.

Textiles & Furniture:

This VOC emission testing is also done on mattresses, textiles, upholstery, and carpets. Also, this helps in the evaluation of the impact on air quality in the indoor environment. This emission testing is great for products that are used in commercial and residential spaces.

Automotive Industry:

Emission testing is mostly performed on the interior of vehicles. This includes dashboards, carpets, and seats that comply with automotive standards. Also, it is helpful in the assessment of health risks that are associated with the exposure of VOCs inside the facilities and vehicles.

Electronics:

Electrical devices and electronics also emit VOCs. These emissions come from adhesives, coatings, and other components. This testing helps in the development of environmental-friendly electronics that have reduced sources of emissions.

Consumer-Related Products:

Various products include personal care products, air fresheners, and cleaning products that release harmful VOCs into the environment. So, this emission testing helps detect health risks and leads to the development of safe alternatives for these products.

R & D:

Emission testing is an important part of research and development. This helps in the manufacturing of new products or materials that have low emissions. Thus, helps to evaluate the emissions, prototypes, and emission-reducing strategies.

Defense & Aerospace:

VOC emission testing is important for spacecraft, aircraft components, equipment, and interior materials. These products need to comply with aviation standards and regulations. So, this maintains a healthy environment that supports the manufacturing of aerospace systems that release low emissions.

Conclusion: The Importance of VOC Emission Testing Chambers

In conclusion, VOC test chambers play one of the most important roles in the world where we need to keep human health and environmental conditions in mind. These VOC test chambers always make products that comply with international standards. When these manufactured products ensure the release of low emissions, this helps us to access the quantification of VOCs and give accurate measurements.

One of the most important significances of these test chambers goes beyond compliance and regulation. This development of products leads to more environmental responsibility and fosters innovations. Moreover, this testing helps to improve the well-being and health of the people living in commercial, educational, and residential spaces. These VOC chambers are vital tools that lead to compliance, air quality assessment, development of products, and reduction of environmental impact. The utilization of this emission testing promotes a healthy environment, reduces negative health impacts as well as improves sustainability.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]