An environmental test chamber is an enclosed area with specific conditions for maintenance. This test chamber is also known as an environmental chamber or climatic chamber. Different types of technical pieces in chambers are capable of stimulating different conditions. The regulation of these conditions uses a series of computers when required for a long time. The size of the test chamber ranges from 1/5 cubic feet to 12,000 cubic feet in controlled specific rooms. It is important to maintain controlled environment chambers for 10 years.

How Does Environmental Test Chamber Work?

The basic principle is to maintain specific conditions through mechanical processes. These chambers have various systems for controlling environmental conditions depending on their use. When using these test chambers, keep several things in mind. The circulation of air, cooling, refrigeration, heating, control humidity, and salt spray.

The circulation of air is important for testing to maintain the conditions. The conditions are necessary to maintain both inside the chamber and the lab. Both these factors are powerful enough that drive accurate results. Also, these climate chambers have a combination of fan and baffle. This combination optimizes humidity and temperature conditions in the lab.

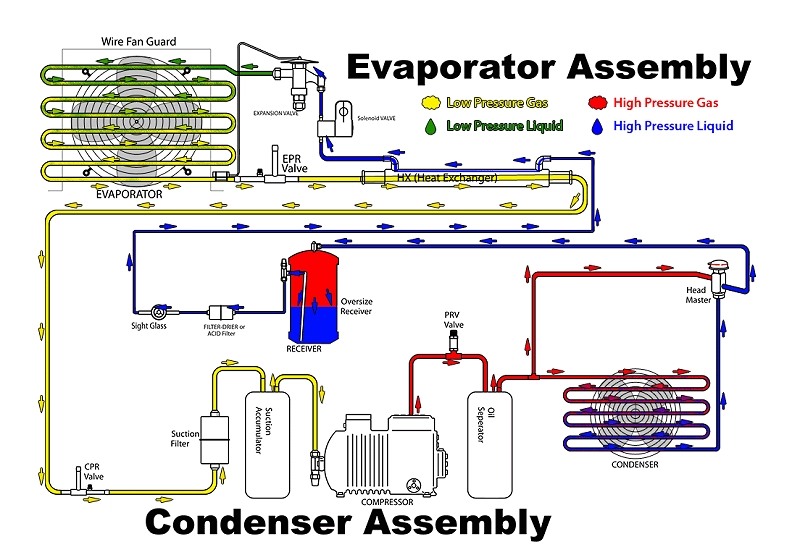

After testing the circulation of air, next comes the cooling and refrigeration. These chambers should have a low temperature, i.e. 70 °C. The refrigeration machines have different pulldown rates from 2.5-10°C in 1 minute. It is easy to maintain a small and sealed system rather than a large one. In the cooling step, add different supplements like CO2 or liquid nitrogen. These supplements are for low temperatures and faster cooling rates.

In the heating phase, they have electric heaters to create a fast response and air passage. Some of the standard models have 120°C with a precision less or equal to 0.5. Keep in mind to maintain the performance rate of test chambers during cooling and heating.

It is also important to create proper humidity during the working of test chambers. Custom-fit vapor steam generators attached to the chambers. These generators rely on a water source that produces humidity of 20-95%. While using the special devices, humidity regulates from 10-98%. If the test needs humidity of low than 5%, it is necessary to add air dryers to the climate test chambers.

After that, it is important to create a salt spray that is first prepared and stored. The compressed air in the tank forces the water and solution to move from the nozzle and creates a fine mist. These chambers have a clear wall to make the product visible during the testing phase.

Types of Environmental Simulation Chambers

3 different types of environmental test chambers include:

- Temperature & Humidity Chambers

Temperature testing is important to perform on a product before it goes to the market. The most common product failure occurs in foods, beverages, cosmetics, electronics, and pharmaceuticals. In these chambers, the temperatures go from -70°C to 180°C. The products come in contact with different temperatures. This tells how much these products withstand the conditions. Other than the temperature, humidity is also a factor in the product failure. This temperature humidity chamber creates various climate conditions for data collection.

- Thermal Shock Chambers

Some components of aerospace, and equipment like telecommunication and military, need high testing. These products withstand extreme cold and heat for a long time due to temperature changes. Thermal shock tests replicate extreme conditions and provide a large data to the engineers. This data serves as a product’s proof related to its durability and quality.

- Combined Test Chambers

Combined test chambers provide a comprehensive testing solution. This testing exposes products to varying climatic conditions and mechanical stress. They aim to replicate actual operating conditions. Vibration test systems check mechanical stress along all three axes using various methods. The main vibration test systems include mechanical, hydraulic, and electrodynamic. Each one replicates different types of mechanical stress. These 3 types of vibration tests are suitable for simulating the required conditions.

Uses of Environmental Test Chamber

The basic purpose of the test chambers is to stimulate the conditions that a product faces when it is in its use phase. During the planning, engineers anticipate the durability of the designs and test for predictions using these chambers.

Thermal Testing

The basic purpose is to stimulate the conditions that a product faces when it is in its use phase. During the planning, engineers see the durability of the designs. Also, they do further testing for predictions.

Humidity Test

After temperature, humidity is the second most crucial factor that contributes to the degradation of products. Moisture, in any form, can cause substantial harm to materials, substances, and products. Humidity is a major concern as it includes both the temperature and the moisture content.

Thermal Shock Test

Thermal shock testing is a method of testing a product’s response to temperature changes. A product may encounter temperature gradients of varying degrees throughout its lifespan. On the other hand, in conventional testing for temperature, the product is continuously exposed to the same temperature for a longer period.

Pressure Testing for Air

When products are transported by air or truck, the air pressure can fluctuate. To determine the level of air pressure that the product can withstand, it is exposed to different pressure levels within an environmental chamber.

Fast Aging Test

This test is conducted to check the lifespan of the product. In this testing, the product is subjected to stress that is specifically designed to reduce the process of aging. The process takes a long time for product testing.

Altitude Testing

The purpose is to determine the high-pressure effects on the sample while maintaining the vacuum. The range of temperature during the test is -65-150°C at heights ranging from -200 feet to 100,000 feet.

Corrosion Testing

It is designed to determine how corrosion affects the product’s performance. In this test, samples are exposed to a concentrated saline solution for a specific period. Different types of products that are tested include paints, coating, and some other products that are resistant to cause corrosion.

Applications of Testing in Climatic Chambers

A climatic chamber can perform any type of test on products. It is done to comply with the regulations that are given by the official regulatory bodies.

- Industries such as aerospace, defense, and telecommunications demand rigorous testing. These testing involve extreme temperatures, shocks, and vibrations due to the intended use of the final product.

- Telecommunication, air force, and defense need extreme testing that involves exposure to low or high temperatures. Also, exposure to specific vibrations and shocks depends on the use of the final product.

- In the food industry, testing is conducted to determine a product’s shelf life and expiry date under optimal factory conditions. These tests also include the evaluation of packaging and the contact between the packaging and the product.

- Building materials also require testing of different stress levels, i.e. weathering. These materials are affected by stresses so, for a climatic chamber is most necessary for testing materials.

- Industries like cosmetics, pharmaceuticals, and chemical ones have extreme regulations as they directly cause impacts public health.

Conclusion: The Importance of Test Chambers

In conclusion, everyone should know that environmental test chambers are a key tool that ensures that the products available in the market are durable, safe to use, and reliable in every aspect. These test chambers help in reducing the risk of failure of various products, reduces recall costs, and ensure that these products meet the requirement of the regulatory bodies. As industries continue to evolve, using test chambers is not only critical but also meets the increasing demands of the customers. Whichever product requires testing, these climatic chambers stimulate different conditions that a product goes through during its life span. Therefore, it helps to assess the stability and performance of the product designs before they go into the market. By using this data from the environmental chambers, engineers can make improvements and adjustments to the materials and designs. This leads to less failure of products in the growing market.

For more environmental test chamber, Please visit: https://chiuventionclimatechamber.com

For more environmental test simulation programmes,environmental testing knowledge, instrument knowledge, and environmental testing laboratory knowledge, please contact us: [email protected]