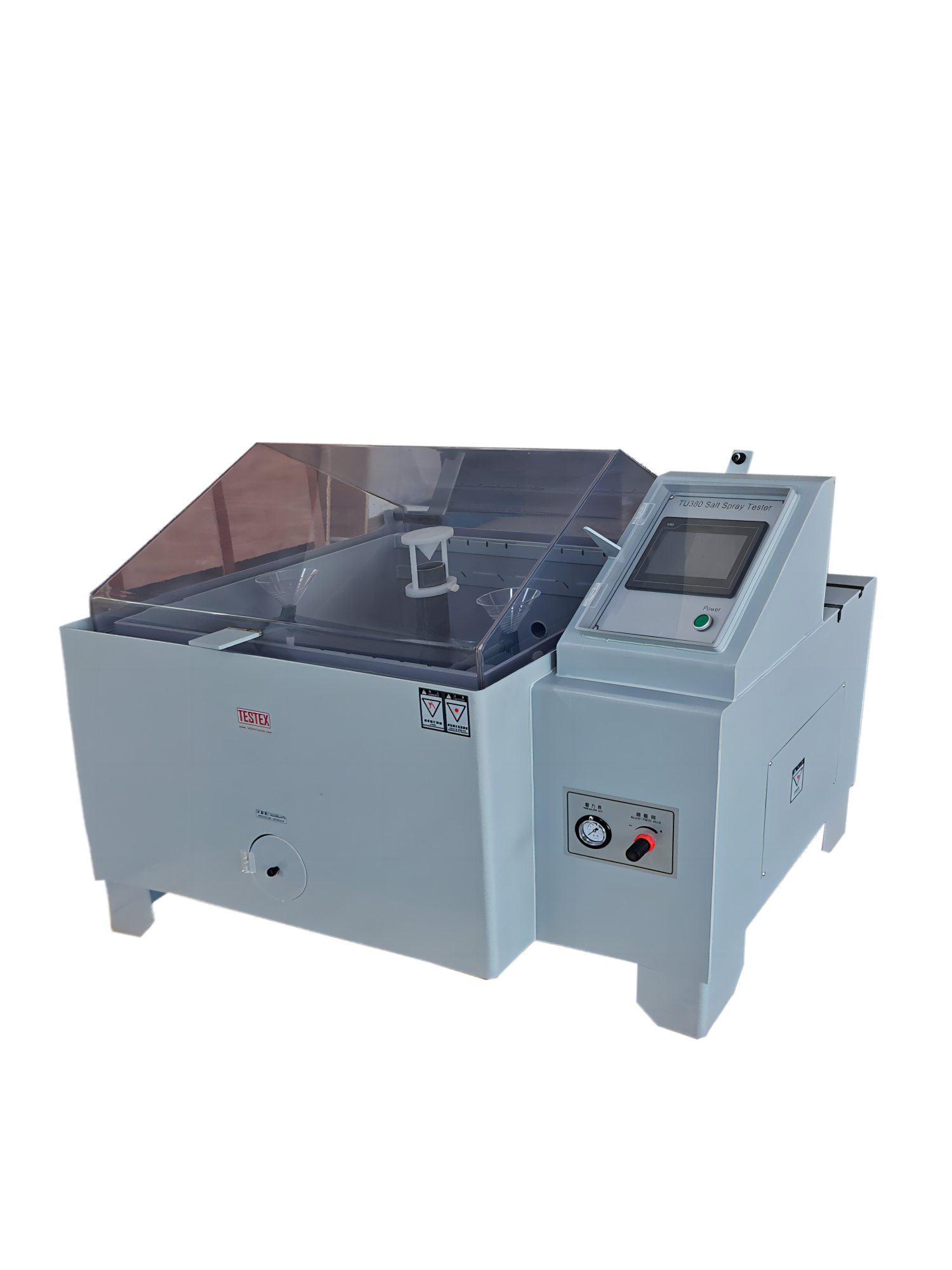

Salt spray test chambers are essential tools in the materials testing industry, primarily used to assess the corrosion resistance of various materials and coatings. These chambers simulate harsh environmental conditions by exposing samples to a saline mist, thereby allowing manufacturers to evaluate the long-term durability of their products. However, like any sophisticated equipment, salt spray test chambers require regular maintenance and occasional repairs to ensure optimal performance and accurate results. This article provides a comprehensive guide on how to maintain and repair salt spray test chambers effectively.

Importance of Maintenance

Regular maintenance of salt spray test chambers is crucial for several reasons:

- Accuracy of Test Results: Properly maintained equipment ensures that salt spray test results are reliable and consistent. Any malfunction or degradation in performance can lead to erroneous data, which may result in poor product quality or failure in real-world applications.

- Longevity of Equipment: Routine care can significantly extend the lifespan of the salt spray test chamber. Addressing minor issues before they escalate into major problems can save costs associated with repairs and replacements.

- Safety: Regular inspections and maintenance help identify potential hazards, ensuring that operators work in a safe environment.

- Compliance with Standards: Many industries have strict regulations regarding salt spray test testing procedures. Proper maintenance ensures compliance with these standards, avoiding potential legal issues.

Key Maintenance Practices

1. Regular Cleaning

Cleaning is one of the most critical aspects of maintaining a salt spray test chamber:

- Interior Cleaning: After each salt spray test, rinse all internal surfaces with warm water to remove salt deposits. Avoid using abrasive materials or solvents that could damage the salt spray test chamber’s interior.

- Nozzle Maintenance: Regularly inspect and clean the nozzles to prevent clogging from salt buildup. Use a soft brush or cloth for cleaning.

- Exterior Cleaning: Wipe down the exterior surfaces with a damp cloth and mild detergent to keep the chamber looking presentable and functioning well.

2. Inspecting Components

Regular inspections are essential for identifying wear and tear:

- Check for Leaks: Inspect all seals, hoses, and connections for signs of leaks. Address any leaks promptly to prevent further damage.

- Examine Electrical Systems: Regularly check electrical connections and components for signs of wear or corrosion.

- Inspect Air Compressors: Ensure that air compressors are functioning correctly by checking for unusual noises or vibrations.

3. Calibration

Calibration is vital for ensuring accurate test results:

- Frequency: Calibrate the salt spray test chamber according to ChiuVention’s recommendations, typically every six months or after significant repairs.

- Calibration Procedures: Follow detailed calibration procedures as outlined in the operation manual. This may involve using reference standards to verify that temperature, humidity, and pressure readings are accurate.

4. Water Management

Proper water management is crucial for optimal performance:

- Saturator Maintenance: Regularly check the water level in the saturator and refill it as necessary. Ensure that clean water is used to prevent contamination.

- Salt Solution Replacement: Replace the salt solution at least once a week or more frequently if it shows signs of contamination or degradation.

- Draining Procedures: If the salt spray test chamber will not be used for an extended period, drain all water from the saturator and heating tank to prevent stagnation.

5. Lubrication

Lubrication helps maintain moving parts:

- Air Compressor Lubrication: Ensure that air compressors are lubricated regularly according to manufacturer specifications.

- Moving Parts: Apply lubricant to any moving components as needed to reduce friction and wear.

6. Post-Test Procedures

After conducting tests, follow these procedures:

- Clean Up: Thoroughly clean the chamber after each use to remove any residual saltwater or debris.

- Inspect Samples: Check samples for any contamination that may affect future tests.

- Documentation: Keep detailed records of maintenance activities, including cleaning schedules, calibration dates, and any repairs performed.

Troubleshooting Common Issues

Despite regular maintenance, issues may arise with salt spray test chambers. Here are some common problems and their solutions:

1. Inconsistent Salt Spray Test Results

If you notice variations in test results:

- Check Calibration: Ensure that the salt spay chamber is properly calibrated.

- Inspect Environmental Conditions: Verify that temperature and humidity levels are within specified ranges.

- Sample Preparation: Ensure that samples are prepared consistently according to testing protocols.

2. Clogged Nozzles

Clogged nozzles can disrupt testing:

- Cleaning Method: Remove nozzles carefully and clean them using appropriate solvents or ultra-fine wire brushes.

- Regular Maintenance Schedule: Implement a routine cleaning schedule specifically for nozzles.

3. Electrical Failures

If electrical components fail:

- Inspect Wiring: Check for loose connections or damaged wires.

- Consult Manufacturer Support: If issues persist, contact technical support for assistance.

4. Hydraulic Issues

For chambers utilizing hydraulic systems:

- Check Fluid Levels: Ensure hydraulic fluid levels are adequate.

- Inspect Seals and Hoses: Look for leaks or signs of wear on hydraulic components.

Repairing Salt Spray Test Chambers

When repairs are necessary, follow these guidelines:

1. Identify the Problem

Before attempting repairs, thoroughly diagnose the issue:

- Gather information from operators regarding symptoms observed during testing.

- Review maintenance logs for any recent changes or issues noted.

2. Consult Documentation

Refer to the operation manual provided by the manufacturer:

- Follow the troubleshooting steps outlined in the manual.

- Use diagrams and schematics to understand component layouts.

3. Perform Repairs Safely

When conducting repairs:

- Disconnect power sources before servicing electrical components.

- Use appropriate tools and safety equipment when handling machinery.

4. Replacement Parts

If components need replacement:

- Use only manufacturer-approved parts to ensure compatibility.

- Keep an inventory of commonly replaced parts on hand for quick repairs.

Conclusion

Maintaining a salt spray test chamber is essential for ensuring accurate testing results, prolonging equipment lifespan, and maintaining safety standards in laboratory environments. By following regular cleaning protocols, conducting thorough inspections, calibrating equipment regularly, managing water levels effectively, lubricating moving parts, and addressing issues promptly through troubleshooting and repair procedures, operators can significantly enhance the reliability of their salt spray test chambers. A proactive approach to maintenance not only minimizes downtime but also ensures compliance with industry standards, ultimately leading to better product quality and customer satisfaction. By investing time and resources into proper care for these vital testing machines, organizations can achieve consistent results in their corrosion resistance evaluations and maintain a competitive edge in their respective markets.